11

ENGLISH

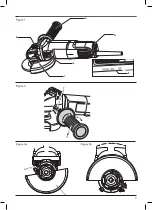

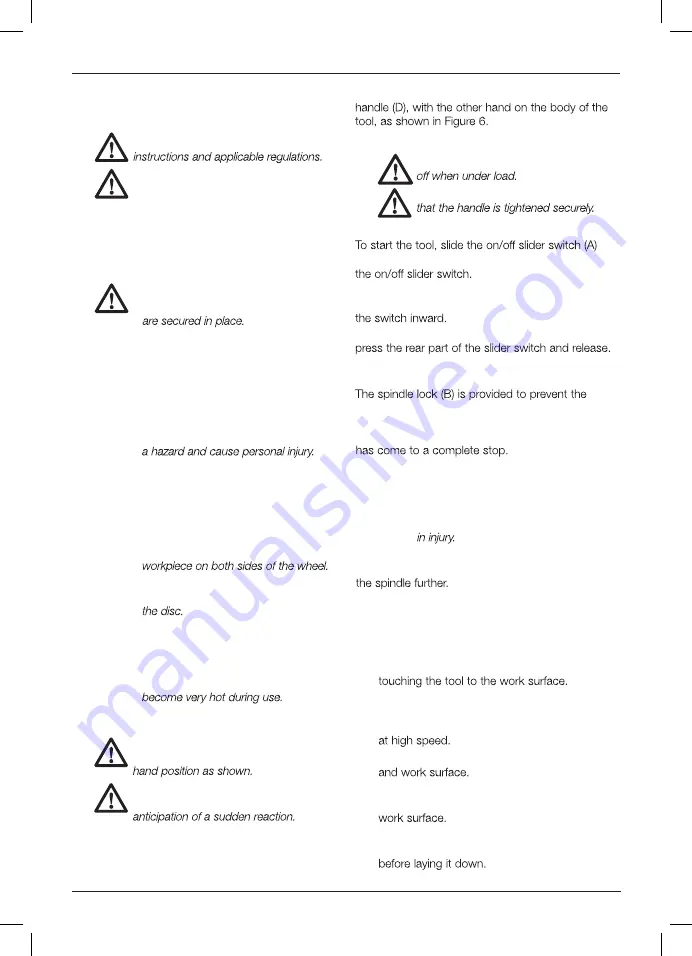

Proper hand position requires one hand on the side

Switches

WARNING:

Do not switch the tool on or

WARNING:

Before using the tool, check

SLIDER SWITCH (FIG. 1)

toward the front of the tool. To stop the tool, release

For continuous operation, slide the switch toward

the front of the tool and press the forward part of

To stop the tool while operating in continuous mode,

Spindle Lock (Fig. 1)

spindle from rotating when installing or removing

wheels. Operate the spindle lock only when the tool

prevent movement of the workpiece

and loss of control. Movement of the

workpiece or loss of control may create

•

Support panels or any oversized

workpiece to minimize the risk

of wheel pinching and kickback.

Large workpieces tend to sag under

their own weight. Supports must be

placed under the workpiece near the

line of cut and near the edge of the

• Apply only a gentle pressure to the

tool. Do not exert side pressure on

• Avoid overloading. Should the tool

become hot, let it run a few minutes

under no load condition to cool the

accessory. Do not touch accessories

before they have cooled. The discs

Proper Hand Position (Fig. 1, 6)

WARNING:

To reduce the risk of serious

personal injury,

ALWAYS

use proper

WARNING:

To reduce the risk of serious

personal injury,

ALWAYS

hold securely in

OPERATION

Instructions for Use

WARNING:

Always observe the safety

WARNING: To reduce the risk

of serious personal injury, turn

tool off and disconnect tool from

power source before making any

adjustments or removing/installing

attachments or accessories.

Be sure

the trigger switch is in the OFF position.

An accidental start-up can cause injury..

WARNING:

• Ensure all materials to be ground or cut

• Secure and support the workpiece.

Use clamps or a vice to hold and

support the workpiece to a stable

platform. It is important to clamp and

support the workpiece securely to

is turned off, unplugged from the power supply, and

NOTICE:

To reduce the risk of damage

to the tool, do not engage the spindle

lock while the tool is operating. Damage

to the tool will result and attached

accessory may spin off possibly resulting

To engage the lock, depress the spindle lock button

and rotate the spindle until you are unable to rotate

Using Depressed Centre Grinding

Wheels

SURFACE GRINDING WITH GRINDING WHEELS

1. Allow the tool to reach full speed before

2. Apply minimum pressure to the work surface,

allowing the tool to operate at high speed.

Grinding rate is greatest when the tool operates

3. Maintain a 20° to 30° angle between the tool

4. Continuously move the tool in a forward and

back motion to avoid creating gouges in the

5. Remove the tool from work surface before

turning tool off. Allow the tool to stop rotating

Summary of Contents for DWE4119

Page 1: ...DWE4119 ...

Page 2: ...English 5 original instructions ...

Page 3: ...3 A D E D F C E B D A C M L 2 ...

Page 4: ...4 H G K J I K I H G ...

Page 15: ......

Page 16: ...N855938 05 2020 ...