English

8

a ratcheting feature. Your grinder offers two options for

this adjustment.

•

One-touch

TM

:

In this position the engaging face

is slanted and will ride over to the next alignment

hole when guard is rotated in a clockwise direction

(spindle facing user) but self-locks in the counter-

clockwise direction.

•

Two-touch

TM

:

In this position the engaging face is

straight and squared off. It will NOT ride over to the next

alignment hole unless guard release lever is pressed and

held while simultaneously rotating the guard in either

a clockwise or counter-clockwise direction (spindle

facing user).

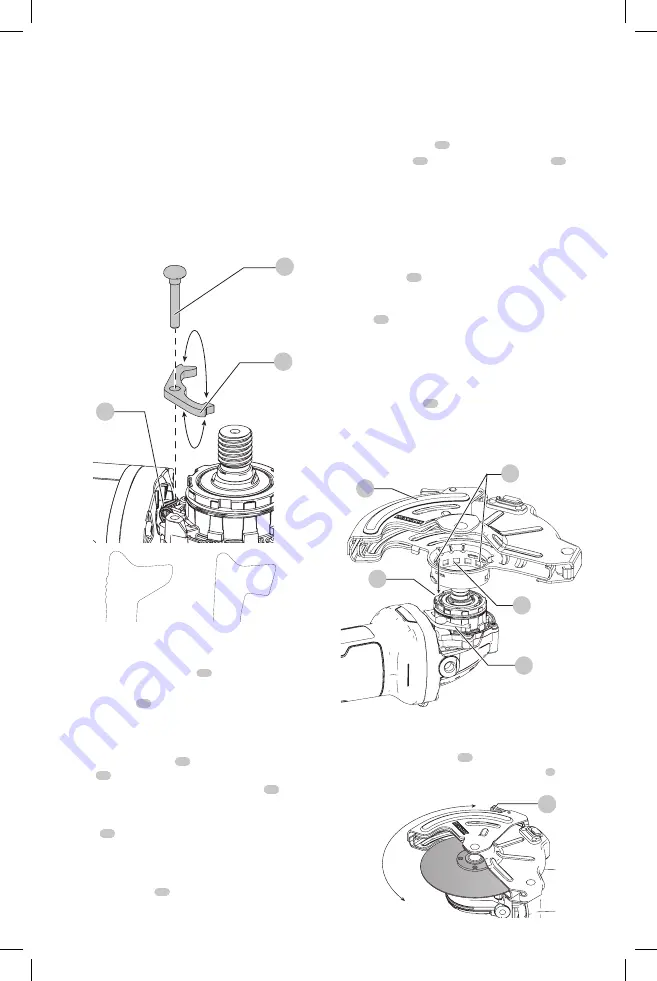

Fig. C

15

16

17

One-Touch

TM

Two-Touch

TM

setting guard Adjustment Options

To adjust the guard release lever

15

for desired

adjustment option:

1. Remove screw

16

using a T20 bit.

2. Remove the guard release lever taking note of the

spring position. Choose the end of the lever for the

desired adjustment option. One-touch will use the

slanted end of the lever

15

to engage the alignment

holes

13

on the guard collar. Two-touch will use the

squared end to engage the alignment holes

13

on the

guard collar.

3. Replace the lever, positioning the chosen end under the

spring

17

. Ensure the lever is in proper contact with

the spring.

4. Replace screw and torque to 2.0-3.0N-m. Ensure proper

installation with spring return function by depressing

guard release lever

15

.

Mounting guard (Fig. D)

CAUTION:

Prior to mounting guard, ensure the screw,

lever, and spring are fitted correctly before mounting

the guard.

1. With the spindle facing the operator, press and hold the

guard release lever

15

.

2. Align the lugs

12

on the guard with the slots

18

on

the gear case cover.

3. Push the guard down until the guard lugs engage

and rotate them in the groove on the gear case cover.

Release the guard release lever.

4. To position the guard:

One-touch

TM

:

Rotate the guard clockwise into the

desired working position. Press and hold the guard

release lever

15

to rotate the guard in the counter-

clockwise direction.

Two-touch

TM

:

Press and hold the guard release

lever

15

. Rotate the guard clockwise or counter-

clockwise into the desired working position.

nOTE:

The guard body should be positioned between

the spindle and the operator to provide maximum

operator protection.

The guard release lever should snap into one of the

alignment holes

13

on the guard collar. This ensures

that the guard is secure.

5. To remove the guard, follow steps 1–3 of these

instructions in reverse.

11

Fig. D

12

13

15

18

To Adjust the heavy-Duty Cut-off guard: (Fig. D, E)

When application allows and/or greater guard coverage

is preferred, the outer guard

11

can be adjusted closed

by pressing the guard opening adjustment lever

9

and

rotating the outer guard to the desired position.

Fig. E

9