English

11

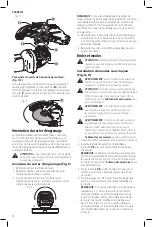

Fig. J

DWE46144n

DWE46166n

5

5

Trigger Switch and Lock-off Lever (Fig. K)

DWE46166N

WARNING:

Before using the tool, check that the side

handle is tightened securely.

CAUTION:

Hold the side handle and body of the tool

firmly to maintain control of the tool at start up and

during use and until the wheel or accessory stops

rotating. Make sure the wheel has come to a complete

stop be fore laying the tool down.

1. To turn the tool on, push the lock-off lever

3

toward

the back of the tool, then depress the trigger switch

1

.

The tool will run while the switch is depressed.

2. Turn the tool off by releasing the releasing switch.

WARNING:

Allow the tool to reach full speed before

touching tool to the work surface. Lift the tool from

the work surface before turning the tool off.

Fig. K

1

3

Paddle Switch (Fig. A)

DWE46144N

CAUTION:

Hold the side handle and body of the tool

firmly to maintain control of the tool at start up and

during use and until the wheel or accessory stops

rotating. Make sure the wheel has come to a complete

stop be fore laying the tool down.

nOTE:

To reduce unexpected tool movement, do not

switch the tool on or off while under load conditions. Allow

the grinder to run up to full speed before touching the work

surface. Lift the tool from the surface before turning the tool

off. Allow the tool to stop rotating before putting it down.

1. To turn the tool on, push the lock-off lever

3

toward

the back of the tool, then depress the paddle switch

2

.

The tool will run while the switch is depressed.

2. Turn the tool off by releasing the paddle switch.

Spindle Lock (Fig. A)

The spindle lock

4

is provided to prevent the spindle from

rotating when installing or removing wheels. Operate the

spindle lock only when the tool is turned off, unplugged

from the power supply, and has come to a complete stop.

NOTICE:

To reduce the risk of damage to the tool, do

not engage the spindle lock while the tool is operating.

Damage to the tool will result and attached accessory

may spin off possibly resulting in injury.

To engage the lock, depress the spindle lock button

and rotate the spindle until you are unable to rotate the

spindle further.

Surface Grinding, Sanding and Wire

Brushing (Fig. L)

CAUTION: Always use the correct guard per the

instructions in this manual.

WARNING: Metal dust build-up.

Extensive use

of flap discs in metal applications can result in the

increased potential for electric shock. To reduce

this risk, insert an RCD before use and clean the

ventilation slots daily by blowing dry compressed air

into the ventilation slots inaccordance with the below

maintenance instructions.

To perform work on the surface of a workpiece:

1. Allow the tool to reach full speed before touching the

tool to the work surface.

2. Apply minimum pressure to the work surface, allowing

the tool to operate at high speed. Material removal rate

is greatest when the tool operates at high speed.

Angle

Fig. L

3. Maintain an appropriate angle between the tool

and work surface. Refer to the chart according to

particular function.

Function

Angle

Grinding

20˚-30˚

Sanding with Flap Disc

5˚-10˚

Sanding with Backing Pad

5˚-15˚

Wire Brushing

5˚-10˚