...................Class I Construction

no .......................no load speed

.......................(grounded) n

.........................rated

speed

...................Class II Construction

.......................earthing terminal

(double insulated)

........................safety alert symbol

…/min ............per minute

BPM ...................beats per minute

IPM .................impacts per minute

RPM ...................revolutions per minute

SPM ...............strokes per minute

sfpm ...................surface feet per minute

SAVE THESE INSTRUCTIONS FOR FUTURE USE

Motor

Be sure your power supply agrees with the nameplate marking. Voltage decrease of more than

10% will cause loss of power and overheating. D

E

WALT tools are factory tested; if this tool does

not operate, check power supply.

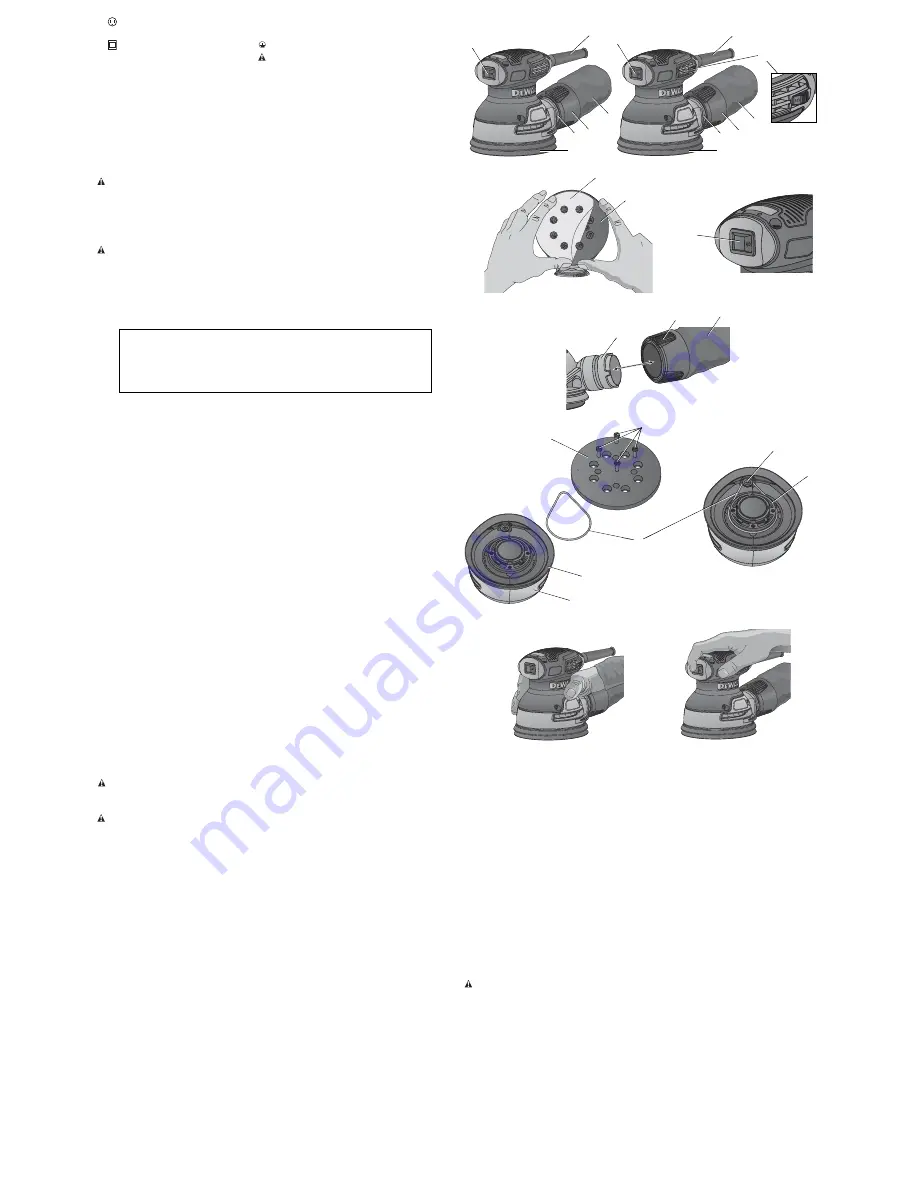

COMPONENTS (FIG. 1)

WARNING:

Never modify the power tool or any part of it. Damage or personal injury could result.

A. On/Off switch

B. Speed control dial (DWE6423)

C. Dust extraction outlet

D. Dust bag

E. Dust bag collar

F. Sanding pad

G. Strain relief

ASSEMBLY AND ADJUSTMENTS

WARNING: To reduce the risk of injury, turn unit off and disconnect it from power

source before installing and removing accessories, before adjusting or when making

repairs.

An accidental start-up can cause injury.

Attaching Sanding Discs (Fig. 2)

Your sander is designed to use 5" (125 mm) sanding discs (H) with an 8-hole dust extraction

pattern. Sanding discs for the DWE6421 and DWE6423 attach with hook and loop. Sanding discs

for the DWE6420 attach using pressure sensitive adhesive (PSA).

REQUIRED SANDPAPERS

Model Sander

Disc Size

Attachment Method

Hole Pattern

DWE6420

5”

PSA

8 Holes

DWE6421

5”

Hook & Loop

8 Holes

DWE6423

5”

Hook & Loop

8 Holes

TO ATTACH SANDING DISC TO THE SANDING PAD (FIG. 2)

1. Turn the sander over so that the sanding pad (F) is facing upward.

2. Clean the dust from the sanding pad (F) face.

3. Hold the pad with one hand to keep it from rotating.

4. With the other hand, align the holes and place the disc (H) directly on top of the pad.

NOTE:

These sanders are not to be used in drywall applications. Using a sanding screen (e.g.,

screen used for sanding drywall) directly on the hook and loop pad will not hold and will damage

the hooks on the pad. The hooks on the pad will wear very rapidly if left in contact with the work

surface while the tool is operating.

Switch (Fig. 3)

To turn the unit on, depress the side of the dust-protected switch (A) that corresponds to the

symbol “I”. To turn the tool off, depress the side of the switch that corresponds to the symbol “O”.

Speed Control Dial (Fig. 1)

DWE6423

The speed control dial (B), shown in Figure 1, allows you to increase or decrease speed from 8,000–

12,000 Orbits Per Minute. The optimal speed setting for each application is very much dependent

on personal preference. Generally, you will want to use a higher setting on harder materials and a

lower setting on softer materials. Material removal rate increases as speed increases.

Dust Extraction (Fig. 4, 5)

Your sander has two dust extraction methods: a built-in outlet (C) which allows either the supplied

dust bag (D) or a shop vacuum system to be connected; and a dust skirt (M, Fig. 5). The built-in

outlet utilizes the D

E

WALT AirLock connection making it compatible with the D

E

WALT dust extractor.

TO ATTACH THE DUST BAG

1. While holding the sander, fit the dust bag collar (E) to the outlet (C) as shown in Figure 4.

2. Turn the collar (E) clockwise to lock the dust bag (D) in place.

TO EMPTY THE DUST BAG

1. While holding the sander, turn the collar (E) counterclockwise to unlock the dust bag (D).

2. Remove dust bag from the sander and gently shake or tap the dust bag to empty.

3. Reattach the dust bag back onto the outlet and lock into place by turning the dust bag collar

clockwise.

You may notice that all the dust will not come free from the bag. This will not affect sanding

performance but will reduce the sander’s dust collection efficiency. To restore your sander’s dust

collection efficiency, depress the spring inside the dust bag when you are emptying it and tap it on

the side of the trash can or dust receptacle.

CAUTION: Never operate these tools unless the dust collector is in place.

Sanding dust

exhaust may create a breathing hazard.

OPERATION (FIG. 6)

WARNING: To reduce the risk of injury, turn unit off and disconnect it from power

source before installing and removing accessories, before adjusting or when making

repairs.

An accidental start-up can cause injury.

NOTICE

: These sanders are not to be used in drywall applications.

NOTICE

: Avoid overloading your sander. Overloading will result in a considerable reduction in

speed and finish quality of your work. The unit may also become hot. In this event, run sander at a

no load condition for a minute or two.

NOTICE

: If you wrap the cord around the tool when you store it, leave a generous loop of cord

such that the strain relief (G) does not bend. This helps prevent premature cord failure.

To operate your sander, grasp it as shown in Figures 6A or 6B and turn it on. Move the unit in long,

sweeping strokes along the surface being sanded, letting the sander do the work.

Pushing down on the tool while sanding actually slows the removal rate and produces an inferior

quality surface. Be sure to check your work often, this sander is capable of removing material

rapidly, especially with coarse paper.

The random orbital action of your sander allows you to sand with the grain or at any angle across

it for most sanding jobs. To produce the best finish possible, start with coarse grit sandpaper and

change gradually to finer and finer paper. Vacuum and wipe surface with a tack cloth between grit

steps. Your sander is designed to sand into small or confined areas. Its small size and light weight

make it ideal for overhead work.

The rate at which the dust collection bag fills up will vary with the type of material being sanded

and the coarseness of the sandpaper. For best results, empty the bag frequently. When sanding

painted surfaces, (see the following for additional precautions when sanding paint) you may find that

the sandpaper loads up and clogs with paint. A heat gun will work much better to remove paint

before sanding. FOLLOW ALL SAFETY INSTRUCTIONS IN HEAT GUN INSTRUCTION MANUAL.

NOTE (DWE6420 ONLY):

When using PSA sanding discs, remove the disc soon after operation.

PSA paper, if the disc is left on during tool storage, sometimes becomes difficult to remove. To aid

in the removal of old PSA paper, sand for a few minutes to soften the adhesive backing prior to

changing disc.

Precautions To Take When Sanding Paint

1. Sanding of lead based paint is NOT RECOMMENDED due to the difficulty of controlling the

contaminated dust. The greatest danger of lead poisoning is to children and pregnant women.

2. Since it is difficult to identify whether or not a paint contains lead without a chemical analysis, we

recommend the following precautions when sanding any paint:

PERSONAL

SAFETY

1.

No children or pregnant women should enter the work area where the paint sanding is being

done until all clean up is completed.

FIG. 3

FIG. 2

2.

A dust mask or respirator should be worn by all persons entering the work area. The filter

should be replaced daily or whenever the wearer has difficulty breathing. See your local

hardware store for the proper NIOSH-approved dust mask.

3.

NO EATING, DRINKING or SMOKING should be done in the work area to prevent ingesting

contaminated paint particles. Workers should wash and clean up BEFORE eating, drinking

or smoking. Articles of food, drink, or smoking should not be left in the work area where

dust would settle on them.

ENVIRONMENTAL

SAFETY

1. Paint should be removed in such a manner as to minimize the amount of dust generated.

2.

Areas where paint removal is occurring should be sealed with plastic sheeting of 4 mils

thickness.

3.

Sanding should be done in a manner to reduce tracking of paint dust outside the work area.

CLEANING AND DISPOSAL

1.

All surfaces in the work area should be vacuumed and thoroughly cleaned daily for the

duration of the sanding project. Vacuum filter bags should be changed frequently.

2.

Plastic drop cloths should be gathered up and disposed of along with any dust chips or

other removal debris. They should be placed in sealed refuse receptacles and disposed of

through regular trash pick-up procedures. During clean up, children and pregnant women

should be kept away from the immediate work area.

3.

All toys, washable furniture and utensils used by children should be washed thoroughly

before being used again.

MAINTENANCE

WARNING: To reduce the risk of injury, turn unit off and disconnect it from power

source before installing and removing accessories, before adjusting or when making

repairs.

An accidental start-up can cause injury.

Replacing the Sanding Pad and the Belt (Fig. 5)

Your sander is equipped with a replaceable belt (L) which is located between the pad (F) and the

sander body (I). It is designed to control the pad speed while the unit is off the work surface. The

belt and the sanding pad (F) are designed to be consumable parts and will occasionally need to be

replaced. The sanding pad needs replacement when signs of wear become evident. Replacement

of the belt is necessary when the pad speed increases very dramatically when the unit is lifted

from the work surface. These parts are available at extra cost from your local dealer or authorized

D

E

WALT service center.

1. Holding the platen firmly, remove the four screws (N) from the bottom of the pad.

2. Remove the pad (F).

3. Replace worn or damaged belt (L) by wrapping it around the shoulder screw (J) and bearing

retainer (K) as shown in Figure 5.

4. Reinstall pad (replace with new pad if necessary). Replace the four screws (N). Be careful not

to over-tighten screws.

FIG. 1

A

H

DWE6420, DWE6421

FIG. 6A

FIG. 6B

DWE6423

A

F

E

D

A

F

E

D

B

E

FIG. 4

C

G

G

C

C

F

D

FIG. 5

I

F

J

K

M

L

N