10

English

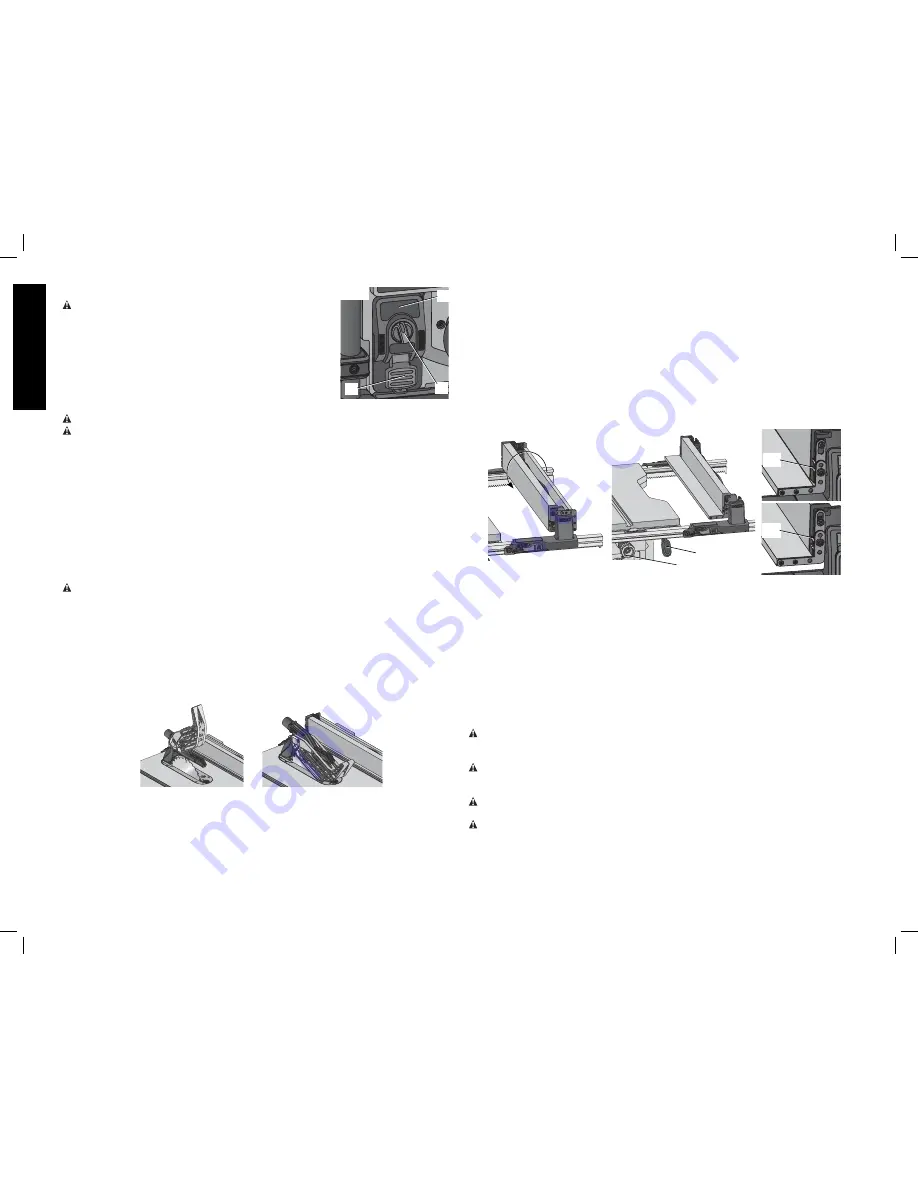

WORK SUPPORT EXTENSION/NARROW RIPPING FENCE

The table saw is equipped with a narrow ripping fence that also supports work that extends

beyond the saw table.

To use the narrow ripping fence in the work support position, rotate it from its stored position

as shown in Figure 31, and slide the pins into the lower sets of slots (A3) on both ends of the

fence.

To use the narrow ripping fence in the narrow ripping position, snap the pins into the upper

sets of slots (A4) on both ends of the fence.

This feature will allow 2" (51 mm) of extra clearance to the blade. Refer to figure 33 B. If more

clearance is necessary, follow directions for making an auxiliary fence under

Narrow Rip

Auxiliary Fence

in the

Operation

section.

NOTE:

When not in use, the narrow ripping fence should be placed in its stored position.

FIG. 31

FIG. 32

D

E

A4

A3

NOTE:

This fence will allow the guard to remain on the saw when completing narrow ripping.

This fence will provide ample space for a push stick. If you prefer more clearance for push

blocks or push sticks, refer to

Narrow Rip Auxiliary Fence

.

FINE ADJUSTMENT KNOB (FIG. 31)

The fine adjustment knob (D) allows smaller adjustments when setting the fence. Before

adjusting, be sure the rail lock lever is in its up or unlocked position.

RIP SCALE POINTER

The rip scale pointer will need to be adjusted for proper performance of the rip fence if the

user switches between thick and thin kerf blades. The rip scale pointer only reads correctly

for position 1 (0 to 24.5"), however for position 1 with narrow rip fence in use add 2" (50 mm).

See

Adjusting the Rip Scale

under

Assembly

.

Ripping (Fig. 33)

WARNING:

Never touch the “free end” of the workpiece or a “free piece” that is cut off,

while the power is ON and/or the saw blade is rotating. Piece may contact the blade resulting

in a thrown workpiece and possible injury.

WARNING:

A rip fence should

ALWAYS

be used for ripping operations to prevent loss of

control and personal injury.

NEVER

perform a ripping operation freehand.

ALWAYS

lock the

fence to the rail.

WARNING:

When bevel ripping and whenever possible, place the fence on the side of the

blade so that the blade is tilted away from the fence and hands.

WARNING:

Keep hands clear of the blade.

On-Off Switch (Fig. 29)

WARNING:

To reduce the risk of injury,

be sure the switch

is in the OFF position before plugging machine in.

Pull the red paddle (H) to turn this saw on and push down the

red paddle to turn the saw off.

LOCK OFF FEATURE INSTRUCTIONS

To lock the saw off, insert a padlock underneath the paddle.

A padlock with a maximum diameter of 1/4" (6.35 mm) and

minimum clearance of 3" (76.2 mm) is recommended.

Guard Detect Operation (Fig 29)

WARNING:

Use the blade guard assembly for all thru-sawing.

WARNING:

Use the riving knife for non thru-sawing when blade guard assembly cannot

be used.

When there is a need for sawing in which the blade guard assembly cannot be used, the

guard detection system provides the user the ability to operate the saw in a bypass mode at

the user's discretion.

1. With the blade guard assembly not installed, switch saw on. The bypass indicator will

flash indicating that the saw cannot be used in this condition.

2. To bypass, rotate the bypass knob once. The flashing light will change to non flashing,

indicating that the saw can be operated once.

3. Additional cutting requires the bypass to be repeatedly activated.

NOTE:

When blade guard assembly is reinstalled, saw will operate without the need to use

the bypass knob.

Guard Operating Feature (Fig. 30)

WARNING: To reduce the risk of injury, turn unit off and disconnect machine from

power source

before installing and removing accessories, before adjusting or changing set-

ups or when making repairs. An accidental start-up can cause injury.

1. The guard(s) will lock in place when in the raised position.

2. This feature increases visability when measuring the blade to fence distance.

3. Push down on guard(s) and they will release to the operating position.

NOTE:

Pull on the anti-kickback assembly to ensure it is locked in place.

ALWAYS

make sure both guards are in the down position in contact with the table before

operating.

FIG. 30

RAISED

POSITION

OPERATING

POSITION

Rip Fence Operation (Fig. 31–32)

RAIL LOCK LEVER (FIG. 32)

The rail lock lever (E) locks the fence in place preventing movement during cutting.

To lock

the rail lever,

push it down and toward the rear of the saw.

To unlock,

pull it up and toward

the front of the saw.

NOTE:

When ripping, always lock the rail lock lever.

FIG. 29

Y

X

H