6

English

FEATURES

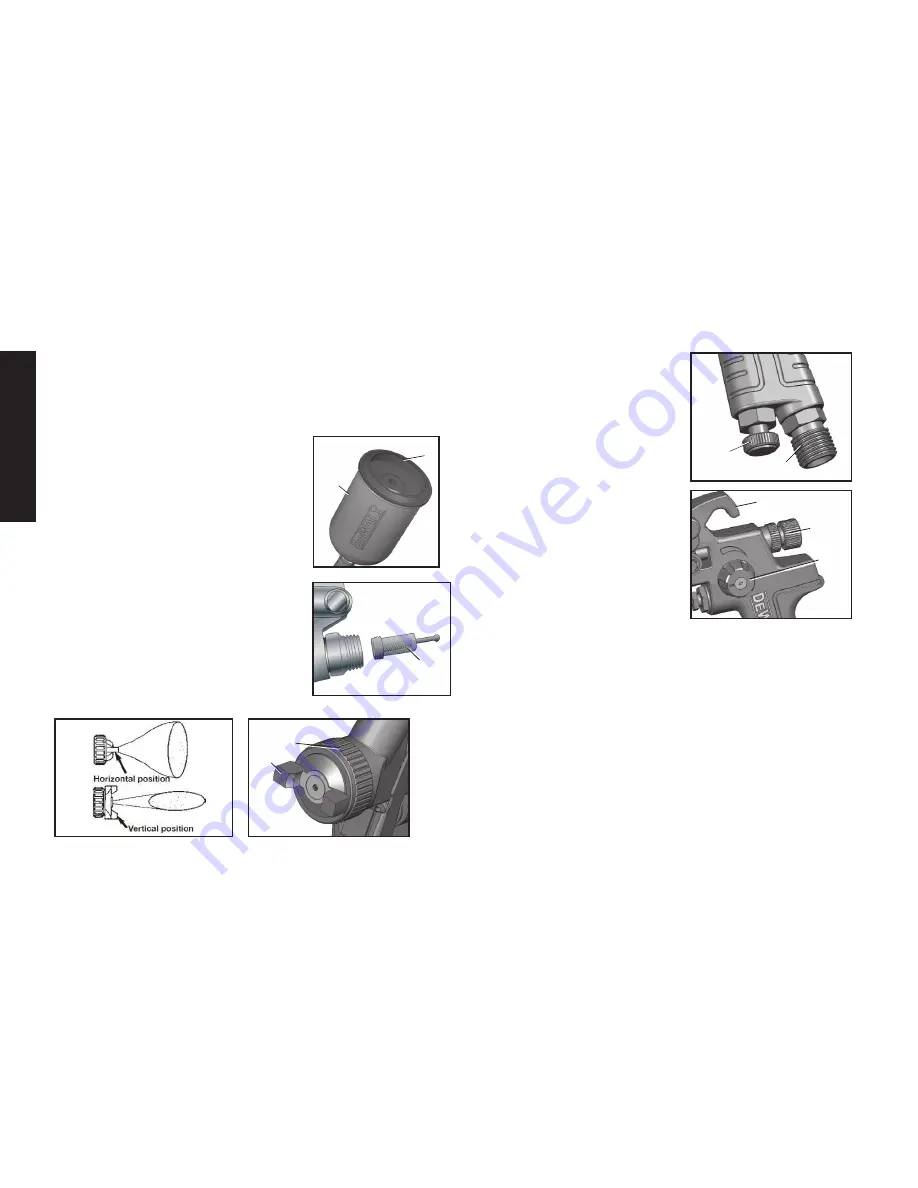

SPraY GUn BoDY

The body of the spray gun is designed to be well-balanced

and lightweight. The body is a compact size and has a fine

spray for precision jobs.

SPraY GUn cUP

The

cup (a) of the spray gun can hold

133 mL (4.5 oz) and has a removable

snap in

lid (K). The design of the spray

gun cup

lid (K) includes a lip around the

edge of the lid for easy removal from the

spray gun cup (a).

MaTerIal FIlTer

The

material filter (B) is used to protect

against contaminants and small par-

ticles.It is located inside of the spray gun,

between the

spray gun cup (a) and air

cap (c).

aIr caP hornS

The position of the

air cap (c) horns (D)

allow two spray patterns.

See Fig. 2.

aIr VolUMe conTrol KnoB

The

air volume control knob (F)

controls the air flow and allows for

a MAX of 30 PSI to reduce over-

spray and efficient air consumption.

aIr InleT

The tool’s

air inlet (G) located at

the bottom of the handle is used

for connecting an air supply that

has a standard 1/4” NPT

American thread.

FlUID conTrol KnoB

The

fluid control knob (I) allows

control of the material amount

released (the density of the

“fan spray”).

PaTTern conTrol KnoB

The

pattern control knob (h) allows

the width of the “fan spray”

to be adjusted.

FIXeD hooK

The spray gun includes a

fixed hook (J) on the body to allow for

convenient hanging when stored.

H

I

J

D

C

F

G

K

A

B