Section 1 Capacitive Discharge (Brushless)

Diagnostic Repair Manual

7

5.

If the field flash was successful, the generator

should produce approximately 240 VAC at the

main circuit breaker of the generator when the

START-RUN-STOP is set to START.

IMPORTANT NOTE:

Do not field flash alternator more

than two times in sequence. If the unit has not produced

power after two attempts, other issues exist and need to

be addressed.

Results

1.

Refer to flow chart.

Test 6 – Check Capacitor

General Theory

The brushless rotor system relies on the charging and

discharging of a capacitor to induce voltage into the rotor,

and also maintains voltage once 240 VAC is achieved. If

the capacitor fails, only residual magnetism of the rotor

will be measured at the main breaker.

NOTE:

The voltage of a brushless capacitive discharge

generator will start low and increase as load is applied.

IMPORTANT NOTE:

The capacitor may need to be

discharged before testing. A capacitor can be discharged

by crossing the terminals with a metal insulated screw

driver.

IMPORTANT NOTE:

Use proper protective equipment

when dealing with a capacitor that has exploded.

Procedure

1.

Consult the owner’s manual of the meter being used

for directions on measuring capacitance.

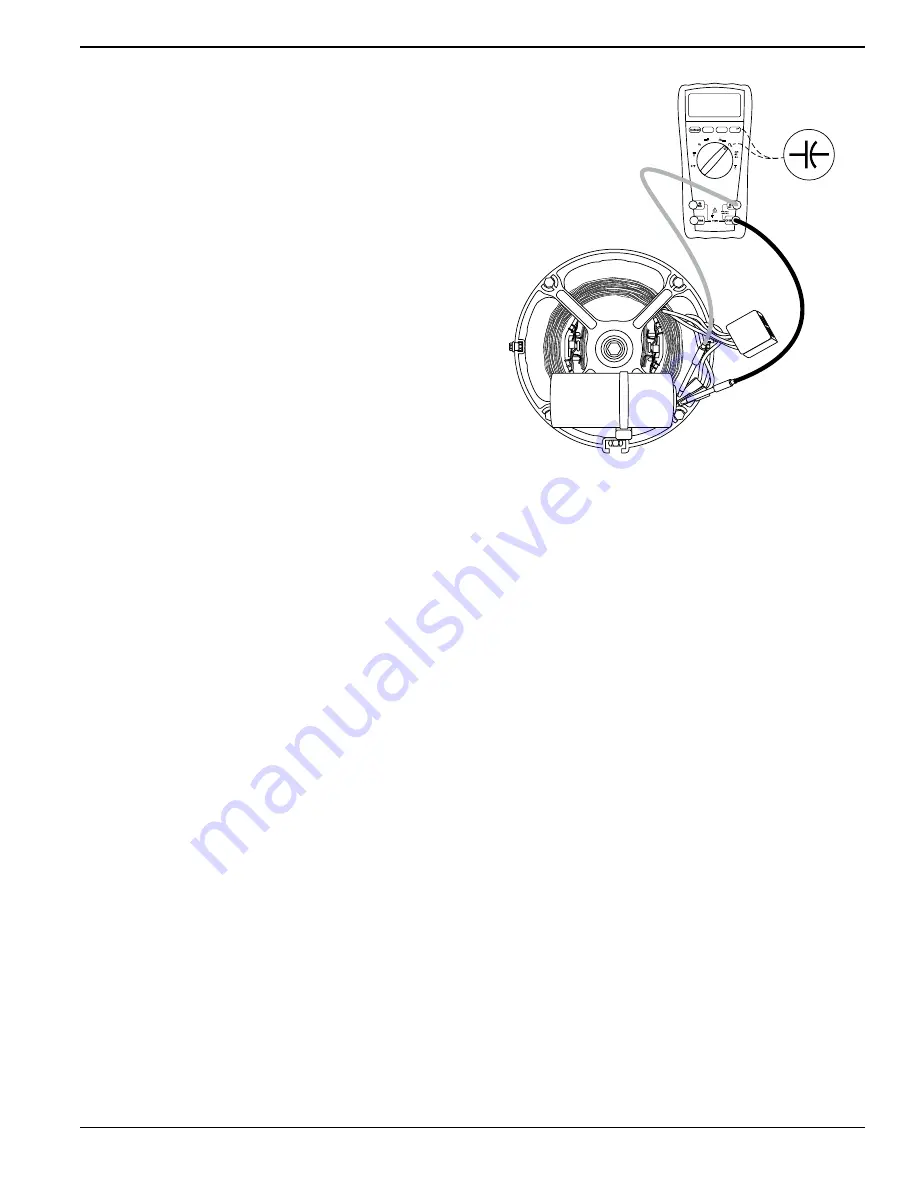

shows a typical meter and how to check capacitance.

2.

Connect meter leads directly across the terminals

of capacitor. The rated µf (micro farad) of the

capacitor is marked on the side of the canister.

3.

The meter should display the correct µf reading ±

5µf. If anything other than the indicated rating is

displayed, replace the capacitor.

Results

1.

Refer to flow chart.

2.

Visually observe the capacitor.

a. A capacitor that has gone bad has a tendency

to explode. Use caution when dealing with an

exploded capacitor, the gel from inside a

capacitor can cause skin irritation.

b. A capacitor is defective if terminal connections

are loose on the canister.

c. A capacitor is defective if it wobbles while

sitting on a flat surface.

d. If any of these traits are observed, replace

capacitor.

Figure 1-9. Capacitor Test Points (Alternator

Configuration “A”)

Test 7 – Test Brushless Excitation

Winding

General Theory

An excitation winding is used to charge a capacitor. It

discharges and charges, releasing a voltage that is

induced into the rotor. If the excitation winding fails, only

residual magnetism of the rotor will be measured at the

main breaker.

NOTE:

The resistance of stator windings is very low. Some

meters will not read such a low resistance, and will simply

indicate CONTINUITY. Recommended is a high quality,

digital type meter capable of reading very low resistances.

IMPORTANT NOTE:

The capacitor may need to be

discharged before testing. A capacitor can be discharged by

crossing the terminals with a metal insulated screw driver.

Procedure

1.

Disconnect Red Wires from capacitor.

2.

Set DMM to measure resistance.

3.

Connect meter leads to excitation winding leads.

a. Reading should be approximately to the values

found in the specifications.

4.

Connect a meter lead to one excitation winding

lead and connect the other meter lead to a clean

frame ground, INFINITY should be measured.

Repeat this step with the other excitation lead.

5.

Isolate the stator wire so the stator is disconnected

from the receptacle panel and the capacitor.

NOTE:

Isolate all main stator leads before proceeding.

003995

59.0

μf