7

ENGLISH

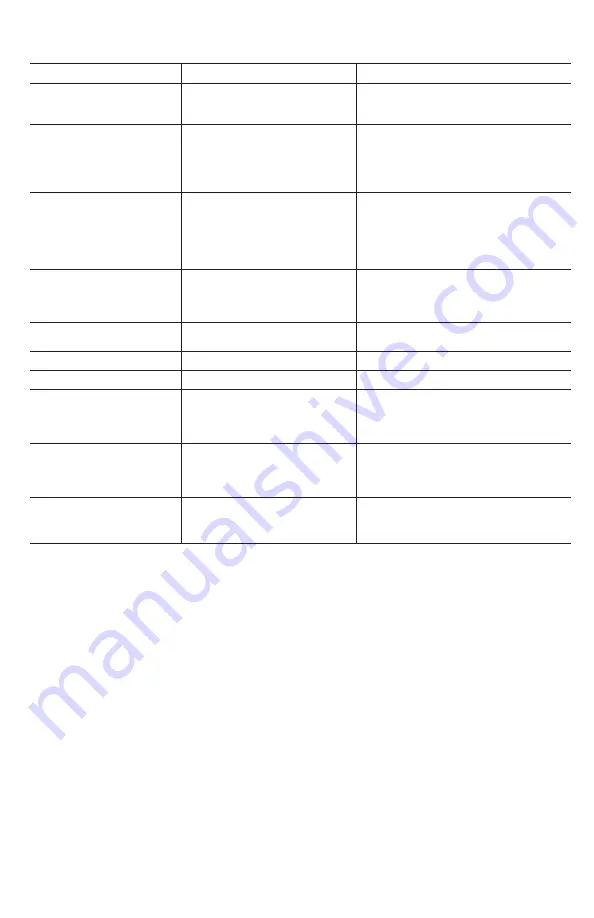

PROBLEM

CAUSE

SOLUTION

Sprayer starts to spray when pumping

or sprayer will not stop spraying when

shut-off lever is released.

Shut-off lock is engaged.

Squeeze shut-off lever and disengage the lock.

See

Pressurizing and Spraying

section

.

Sprayer will not build pressure.

1. Pressure chamber installed into pump.

2. Dirty, damaged or worn pump or chamber

o

o-ring.

3. Dirty poppet in pump.

1. Install pressure chamber as described in

Pressure

C

Chamber Maintenance

section.

2. Clean and lubricate or replace o-rings as described in

S

Seal Servicing

section.

3. Clean sprayer as described in

Cleaning

section.

Sprayer will not spray.

1. Sprayer pressurization.

2. Shut-off clogged.

3. Nozzle clogged.

1. Pressurize sprayer as described in

Pressurizing

and

S

Spraying

section.

2. Clean shut-off as described in

Shut-off Maintenance

s

section.

3. Clean nozzle as described in

Nozzle Maintenance

s

section.

Sprayer leaks from the bottom of

the tank.

1. Loose pump nut.

2. Damaged or worn o-rings or seals.

1. Tighten pump nut as described in

Seal Servicing

se

Section.

2. Replace o-rings and seals as described in

Seal

Se

Servicing

section.

Sprayer leaks where piston rod enters

top of the tank.

Dirty, damaged, or worn grommet.

Clean and lubricate hole in grommet or replace

g

grommet as described in

Seal Servicing

section.

Hose leaks at tank connection.

Cracked, swollen or faulty hose.

Replace shut-off assembly.

Hose leaks at shut-off.

Cracked, swollen or faulty hose.

Replace shut-off assembly.

Pump handle is difficult to operate.

1. Swollen or damaged pump piston o-ring.

2. Dirty, dry or damaged grommet.

1. Clean and lubricate or replace o-ring as described in

S

Seal Servicing

section.

2. Clean and lubricate hole in grommet or replace

g

grommet as described in

Seal Servicing

section.

Nozzle drips when shut-off lever is

released.

1. Dirt or debris in shut-off valve.

2. Damaged o-ring or seal in shut-off.

1. Clean shut-off as described in

Shut-off Maintenance

s

section.

2. Service shut-off seals as described in

Shut-off

M

Maintenance

section.

Nozzle tip leaks, poor spray pattern,

partial spray or complete stoppage.

1. Flat seal is missing or damaged.

2. Spray extension or nozzle clogged.

1. Replace flat seal at extension tip.

2. Remove nozzle and clean as described in

Nozzle

M

Maintenance

section.

TROUBLESHOOTING

© 2020 DEWALT

DEWALT® and GUARANTEED TOUGH® are registered trademarks of

the DEWALT Industrial Tool Co., used under license. All rights reserved.

The yellow and black color scheme is a trademark for DEWALT

Power Tools and Accessories.

Made in China

Manufactured under license and distributed by:

The Fountainhead Group, Inc.

23 Garden Street

New York Mills, NY 13417 U.S.A.

Fax: (315) 768-4220

Email: Info@TheFGI.com

www.TheFountainheadGroup.com

Three Year Limited Warranty

The warranty of this product is covered by:

The Fountainhead Group, Inc. (800)-311-9903

We warrant that each product sold by us will be free from defects in material

and workmanship for a period of three years from the date of shipment by us.

We make no other express warranties, and all implied warranties, including

fitness and merchantability, are limited to three years from the date of shipment

by us. Within the warranty period, we will repair or replace any part found to

be defective upon our examination but will not pay shipping cost or other

expenses. To obtain warranty service, contact us at: The Fountainhead Group,

Inc., c/o Customer Service, 23 Garden Street, New York Mills, New York 13417,

or call prepaid, Area Code (800) 311-9903 or (315) 736- 0037. Merchandise may

not be returned without prior permission and must be returned to us prepaid.

This warranty service is an exclusive remedy and we are not responsible for

any consequential or incidental damages or injury to person(s) or property.

This warranty shall not apply to any product which has been subject to misuse,

negligence or accident, or been damaged in shipment, or misapplied, or which

has been modified or repaired by unauthorized persons. This warranty only

applies to products owned by persons purchasing directly from us or from our

approved distributors and merchandisers. The right is reserved to incorporate

subsequent design or parts changes after publication and without reissue of

descriptive literature or catalogs.

NOTE: Limitations on duration of implied warranty and/or consequential

damages might not apply to you if your state does not permit them. This

warranty gives you specific legal rights in addition to rights you may have under

state law..