9

WARNING!

•

Serious or fatal crashing injuries can occur from furniture tipping

over. To prevent this, the rack must always be secured to a wall,

especially in earthquake-prone environments, where surfaces are

uneven, and where children and/or pets are present.

CROSSBEAM INSTRUCTIONS

•

Note: It is recommended for one person to hold the upright

frames in place while a second person installs the crossbeams.

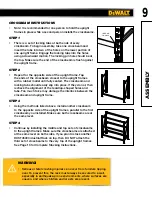

STEP 1

•

There is a set of locking tabs at both ends of every

crossbeam. To begin assembly, take one crossbeam and

insert the tabs into two of the holes on the lower portion of

one upright frame. Engage the locking tabs into the holes

using a downward motion. The locking pin hole should be at

the top. Make sure the end of the crossbeam is flush against

the upright frame.

STEP 2

•

Repeat for the opposite side of the upright frame. Tap

the ends of the crossbeam closest to the upright frames

with a rubber mallet until fully seated. The crossbeam and

locking tabs should easily slip into place. If they do not, then

recheck the alignment of the teardrop-shaped holes and

tabs. Too much force may damage the interlock between the

crossbeam and upright frame.

STEP 3

•

Using the methods listed above, install another crossbeam

to the opposite side of the upright frames, parallel to the first

crossbeam you installed. Make sure both crossbeams are at

the same level.

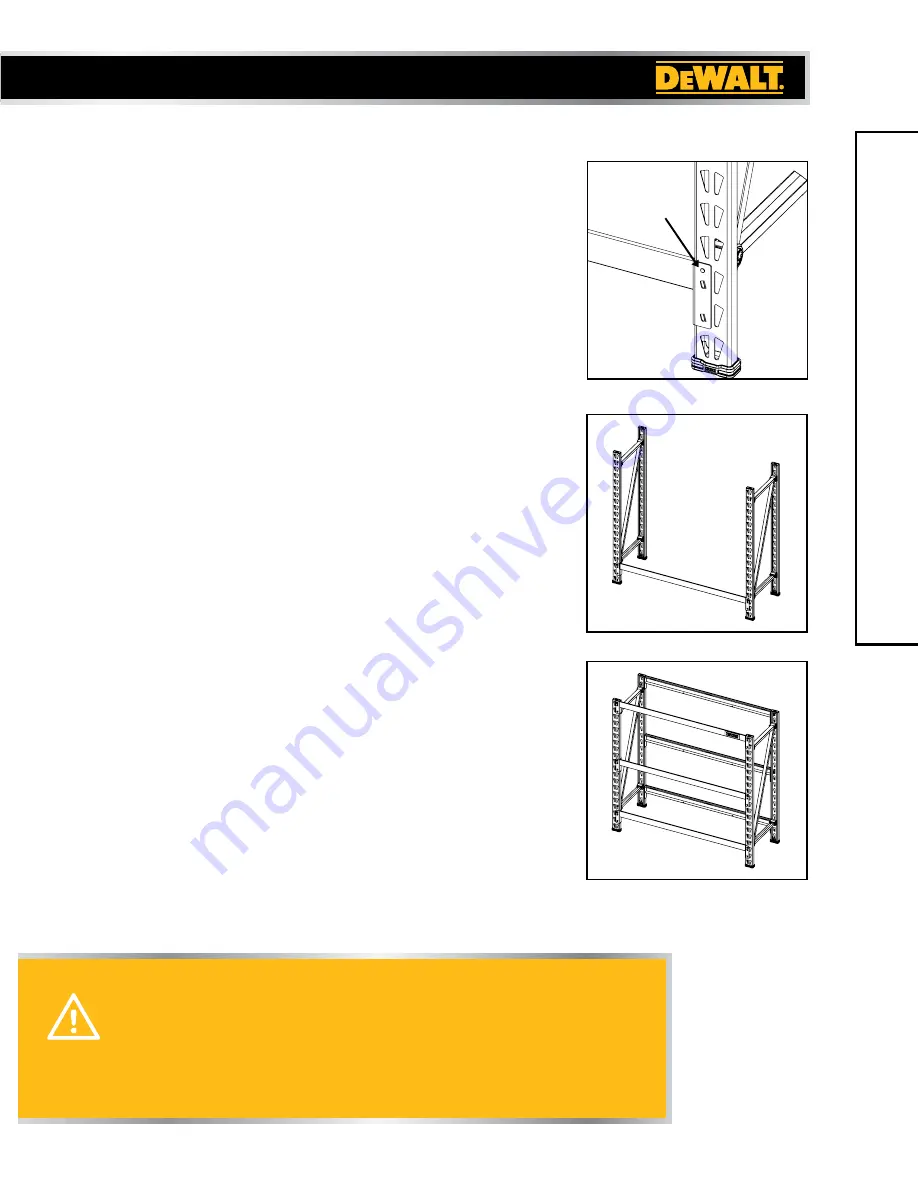

STEP 4

•

Continue by installing the middle and top sets of crossbeams

to the upright frames. Make sure the crossbeams are attached

at the same level on both sides. If you plan to stack another

DXST4500 Industrial Rack on top, then DO NOT attach the

third set of crossbeams to the very top of the upright frames.

See Page 13 for Complete Stacking Instructions.

A

SSEMBL

Y

LOCKING

PIN HOLE

FPO

Summary of Contents for DXST4500

Page 2: ......