8

hole (H), allowing the wall mount to be attached to any surface with a nail or screw.

Once the wall mount is secured, its steel plate provides a surface to which the

magnetic pivot bracket can be attached. The position of the laser can then be

fine-tuned by sliding the pivot bracket up or down on the wall mount.

LEVELING THE LASERS

As long as the DW086-XE and DW087-XE lasers are properly calibrated, the lasers

are self-leveling. Each laser is calibrated at the factory to find level as long as it is

positioned on a flat surface within average ± 4° of level. No manual adjustments must

be made.

MAINTENANCE

• To maintain the accuracy of your work, check the laser often to make sure it is

properly calibrated. See

Field Calibration Check

.

• Calibration checks and other maintenance repairs may be performed by D

E

WALT

service centers.

• When not in use, store the laser in the kit box provided. Do not store your laser at

temperatures below -20

˚

C (-5

˚

F) or above 60

˚

C (140

˚

F).

• Do not store your laser in the kit box if the laser is wet. The laser should be dried

first with a soft dry cloth.

Cleaning

Exterior plastic parts may be cleaned with a damp cloth. Although these parts are

solvent resistant, NEVER use solvents. Use a soft, dry cloth to remove moisture from

the tool before storage.

Field Calibration Check

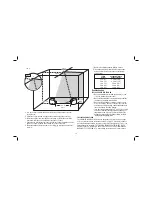

CHECKING ACCURACY – HORIZONTAL BEAM, SCAN DIRECTION (FIG. 6)

Checking the horizontal scan calibration of the laser requires two walls 9 m (30')

apart. It is important to conduct a calibration check using a distance no shorter than

the distance of the applications for which the tool will be used.

1. Attach the laser to a wall using its pivot bracket. Make sure the laser is facing

straight ahead.

FIG. 6

b

Step 1

a

Step 2

45

˚

90

˚

Step 3

Step 4

Step 2

Step 3

2. Turn on the laser’s horizontal beam and pivot the laser approximately 45

˚

so that the right-most end of the laser line is striking the opposing wall at

a distance of at least 9 m (30'). Mark the center of the beam (a).

3. Pivot the laser approximately 90

˚

to bring the left-most end of the laser line

around to the mark made in Step 2. Mark the center of the beam (b).

4. Measure the vertical distance between the marks.

5. If the measurement is greater than the values shown below, the laser must be

serviced at an authorized service center.

Distance

Allowable Distance

Between

Walls Between

Marks

9 m (0')

3.0 mm (1/8")

12 m (40')

4.0 mm (5/32")

15 m (50')

5.0 mm (7/32")

CHECKING ACCURACY – HORIZONTAL BEAM, PITCH DIRECTION (FIG. 7)

Checking the horizontal pitch calibration of the laser requires a single wall at least 9 m

(30') long. It is important to conduct a calibration check using a distance no shorter

than the distance of the applications for which the tool will be used.