Maintenance Manual DG-808C

Issued: July 2017

TN800/45

0.1

0

General

0.1

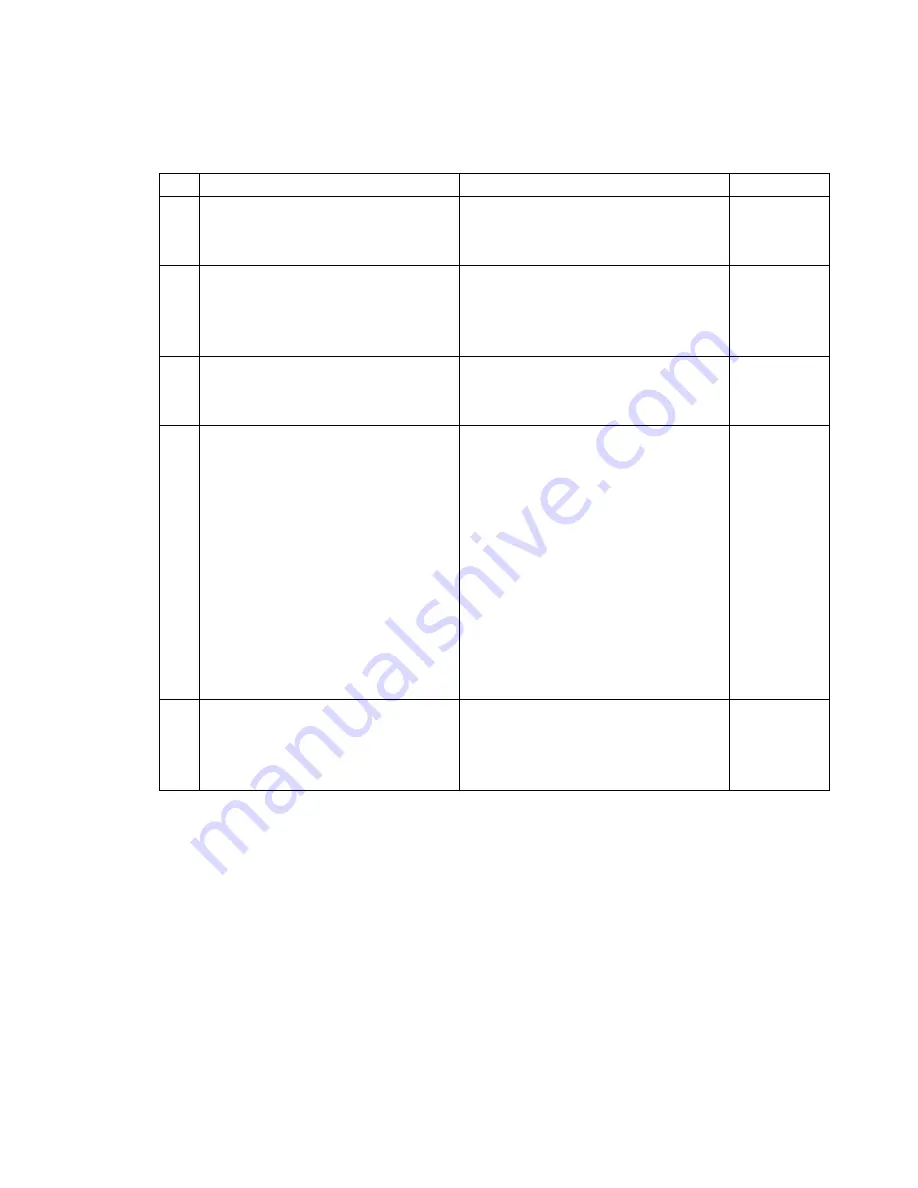

Manual amendments

No. Page

Description

Date

1

0.3, 0.6, 0.10, 1.11, 8.2,

diagrams 5a, 11d, 8EP210

ÄM 800-17-07

Fin tank valve and operating

handle, Refuelling pump

April 2007

2

0.3, 0.4, 0.6, 0.7, 0.10, 0.12,

1.28, 1.29, 2.7, 3.3, 3.5, 3.11,

4.2, 4.8, 4.11, encl. 2 page 1,

TN 4600-2-2 Solo

TN800/34

Manual revision

September

2007

3

0.6, 8.1, diagram 10

TN800/35

Extension-retraction unit, rear

fork of spindle-drive

April 2009

4

0.3 ÷ 0.12, 1.3, 1.5, 1.6, 1.8,

1.10, 1.11, 1.14 ÷ 1.16, 1.24,

1.27, 1.29, 1.30, 2.1, 2.2, 2.6,

2.7, 3.1, 3.3 ÷ 3.11, 4.1 ÷ 4.3,

4.6 ÷ 4.11, 4.13, 4.15, 4.16,

4.18 ÷ 4.23, 4.25 ÷ 4.31, 5.1,

5.2, 6.1 ÷ 6.3, 7.2, 8.1 ÷ 8.4,

9.2,

diagrams 1 ÷ 5, 5a, 8, 9, 10, 11,

11d, 12, 13, 13b, 14, 17,

14a removed,

8M110, 8E250, SI 69-10

TN800/41

Manual revision,

Coolant pump Pierburg

May 2012

5

0.0, 0.1, 0.3 - 0.6, 0.11, 0.12,

2.1, 2.2, 3.7, 4.33, 8.1 - 8.3,

diagrams 3, 9,

8E250h, 8E256b

manual revision,

TN800/45

July 2017

Summary of Contents for DG-800A

Page 3: ...Maintenance Manual DG 808C Issued June 2005 0 2 This page was intentionally left blank...

Page 113: ......

Page 114: ......

Page 115: ......

Page 116: ......

Page 117: ......

Page 118: ......

Page 119: ......

Page 122: ......

Page 123: ......

Page 124: ......

Page 125: ......

Page 126: ......

Page 127: ......

Page 128: ......

Page 129: ......

Page 130: ......

Page 131: ......

Page 132: ......

Page 133: ......

Page 134: ......

Page 135: ......

Page 136: ......

Page 137: ......

Page 138: ......

Page 139: ......

Page 140: ......

Page 141: ......

Page 142: ......

Page 143: ......

Page 144: ......

Page 145: ......

Page 147: ......

Page 158: ......