Maintenance Manual DG-808C

Issued: May 2012

TN 800/41

4.2

4.2

Replacement of control circuit cables

The following cable connections are approved:

3.2 mm dia. control cable construction 7x19 with Nicopress-sleeves 28-3-M

Copper and tool No. 51-M850 or 63-V-XPM or 64-CGMP where the M groove

is to be used.

The above applies to the rudder cables, the tow release cable and the engine

retaining cable.

The cable for the rudder pedal adjustment and the fin tank valve are 1.6 mm dia.

control cable construction 7x7 with Nicopress-sleeves 28-1C Copper and the C

groove for tool 64-CGMP should be used.

The same type of cable is used for the control cables of throttle and manual

propeller brake in Bowden outers with 2.6 mm inside diameter

Attachment of the Nicopress sleeves should only be done using the respective

tool. All the procedures and checks noted by the tool manufacturers should be

followed.

Please refer to aircraft inspection and repair FAA AC 43.13-1 B or later issues.

Caution:

Control cables according to MIL-W-83420 I/A (was MIL-W-1511A)

or ISO 2020 (was LN 9374) should be used.

Note:

For the electric propellerbrake a Bowdencable 1.5 mm 19 x 0.31 with

Bowden outer with Teflon liner 2.5 mm inside diameter should be used instead

of the material mentioned above.

4.3

Adjustment and servicing of the control circuit

a)

In all cases, new self locking nuts DIN 985-8.8 zn or LN 9348 should be

used.

b)

Bolts which are not secured with self-locking locking nuts have to be secured

with Loctite 243. Before installing the bolt clean the thread and the inside

thread. Apply only 1 drop of Loctite on the bolt thread. Too much Loctite

may cause damage when you try to loosen the bolt again.

c)

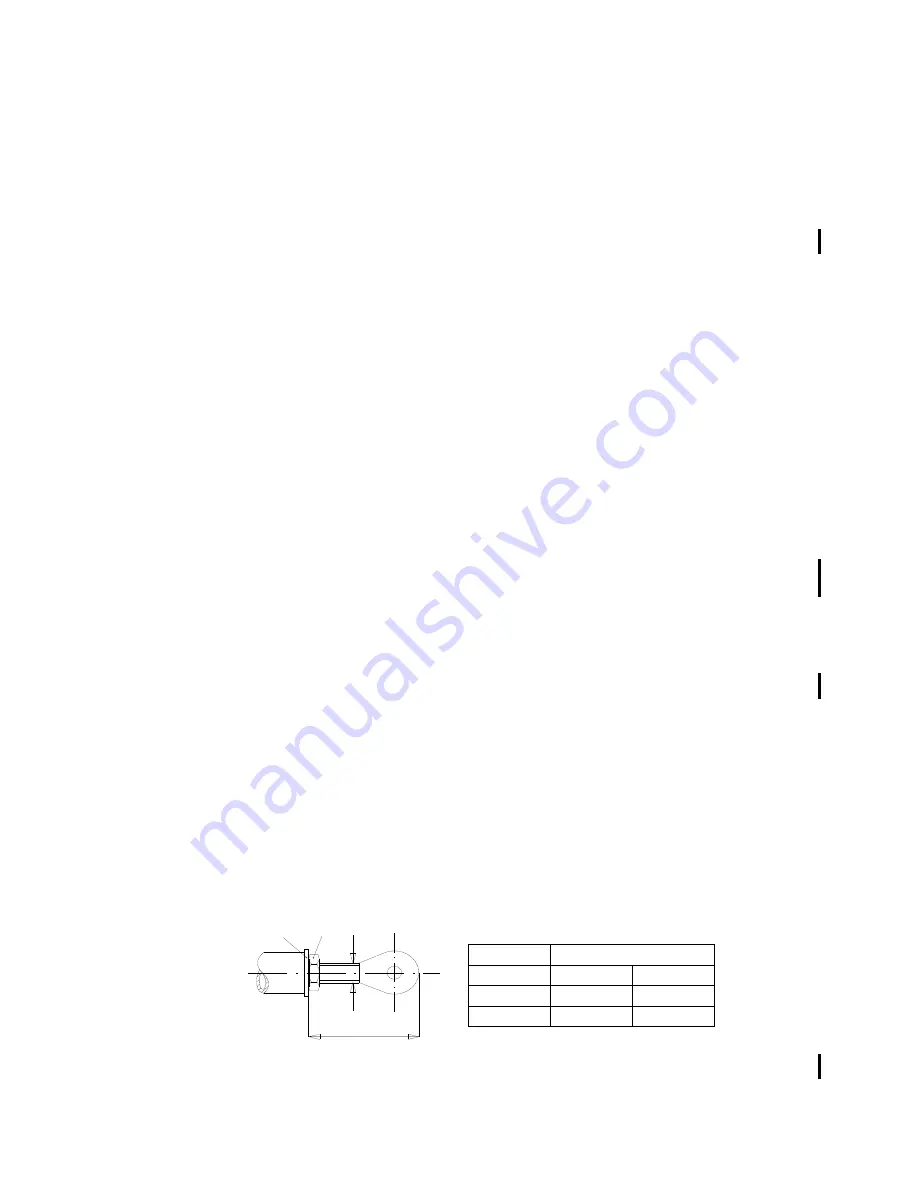

With all adjustment work, it should be ensured that the rod ends are not

screwed out too far from the pushrod - see sketch below for allowable max.

distances for the two sizes used.

Caution:

All lock nuts (B) are secured by a spring washer (C) DIN 6798 I. Be

careful not to loose that washer!

A

max. of x

mm

inch

M 6

36

1.4

M 8

60

2.36

x

A

C

B

Summary of Contents for DG-800A

Page 3: ...Maintenance Manual DG 808C Issued June 2005 0 2 This page was intentionally left blank...

Page 113: ......

Page 114: ......

Page 115: ......

Page 116: ......

Page 117: ......

Page 118: ......

Page 119: ......

Page 122: ......

Page 123: ......

Page 124: ......

Page 125: ......

Page 126: ......

Page 127: ......

Page 128: ......

Page 129: ......

Page 130: ......

Page 131: ......

Page 132: ......

Page 133: ......

Page 134: ......

Page 135: ......

Page 136: ......

Page 137: ......

Page 138: ......

Page 139: ......

Page 140: ......

Page 141: ......

Page 142: ......

Page 143: ......

Page 144: ......

Page 145: ......

Page 147: ......

Page 158: ......