Arc-Zone.com, Inc.

2091 Las Palmas Drive, Ste. F

Carlsbad, CA 92011 - Tel. 1.760.931.1500

Email: info@arc-zone.com

Copyright©2017, Arc-Zone.com®, Inc. All Rights Reserved

8 / 13

Document: DGP-MANUAL-P3-V2 | DGP-PG3-V2 Product User Manual | Released: 7/11 Rev. C

Page 8

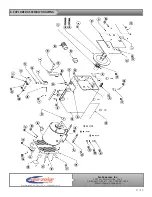

7. WHEEL REPLACEMENT

HOW TO ORDER REPLACEMENT WHEELS

The Piranha III replacement diamond wheels are available either directly through Diamond Ground Products

or through local distributors who sell our products. The part number to use when ordering are listed below in

the ‘”Piranha Grinder Accessories” Chart. These wheels are in stock for immediate delivery. In manufacturing

replacement wheels, a special process is used to bond the diamond to the wheel which makes these wheels last

as long as possible when used for grinding tungsten. Grinding wheels other than DGP wheels will not only offer

less longevity, but may be dangerous and may void the warranty on this equipment.

HOW TO INSTALL REPLACEMENT GRINDING WHEELS

Please use the following steps to remove and replace the Diamond Grinding wheels:

1. Turn the power off, unplug the electrical outlet, and wait until the motor has come to a complete stop.

2. Completely unscrew and remove Handle A (see picture at adjusting handles). Lift up and remove the Arm,

taking care not to lose the washer between the Arm and the Handle. Set them aside.

3. Unscrew the six thumbscrews on the wheel cover. Remove the Wheel Cover to fully expose the Wheel.

4. Using the supplied Allen Wrench, loosen the four screws on the front of the Grinding Disk.

5. Remove the old Wheel and mount the replacement wheel on the arbor.

6. Replace all of the other parts in reverse order the exact same methods you used to remove them.

** IMPORTANT ***

DO NOT REMOVE OR OVER TIGHTEN ARBOR

WHEN CHANGING WHEEL, ONLY REMOVE 4 SCREWS

• For optimum surface finish on .040” through 3/32”, use a 600 Grit Diamond Wheel (DGP-PG1426)

• For optimum wheel life on 3/32” through 3/16”, use a 300 Grit Diamond Wheel (DGP-PG1425)

PART NO. PIRANHA GRINDER ACCESSORIES

DGP-PG1425 Piranha III Grinding Wheel – 300 Grit Single Sided (6” diameter)

DGP-PG1423 Piranha III Grinding Wheel – 150 Grit Single Sided (6” diameter)

DGP-PG1426 Piranha III Grinding Wheel – 600 Grit Single Sided (6” diameter)

All prices are FOB Factory.

Products listed above are normally stock items- consult factory to confirm.

Net 30 terms available O.A.C for deliveries in the U.S. International orders by wire transfer.

Prices that are listed are subject to change without notice.

t

7. WHEEL REPLACEMENT