3. OPERATION

Page 61

© 2008 DH Instruments, a Fluke Company

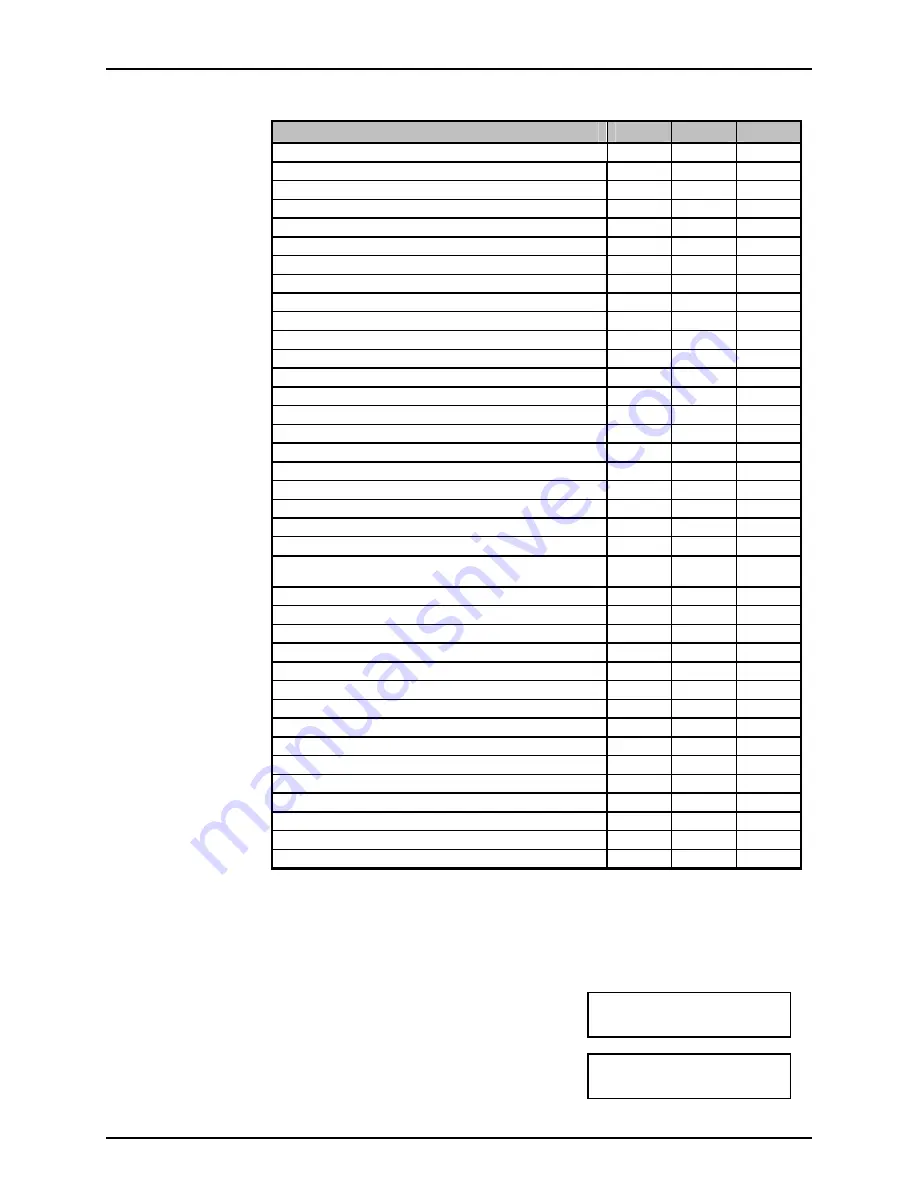

Table 5.

Security levels

FUNCTION

LOW

MEDIUM

HIGH

[RANGE]

•

[ENT] (AutoTest)

•

[UNIT]

•

[MODE]

•

[AutoRange]

• •

[LEAK CK]

•

[DISPLAY]

• •

[HEAD]

•

[SDS] (NOT USED IN THIS RPM4-E-DWT MODEL)

[AutoZ] (in absolute mode)

• •

[SETUP]

•

[SETUP], <1range>

• •

[SETUP], <2res>

• •

[SETUP], <4UL>

• •

[SETUP], <5ATest>

• •

[SPECIAL]

•

[SPECIAL], <1AutoZ>

• •

[SPECIAL], <1AutoZ>, <1on/1off>

• • •

[SPECIAL], <1AutoZ>, <3edit>

• • •

[SPECIAL], <2remote>

•

[SPECIAL], <2remote>,

make changes

• •

[SPECIAL], <3head>

• •

[SPECIAL], <4SDS> (NOT USED IN THIS RPM4-E-DWT

MODEL)

• •

[SPECIAL], <5pref>, <1ScrSvr>

• •

[SPECIAL], <5pref>, <2sound>

• •

[SPECIAL], <5pref>, <3time>

• •

[SPECIAL], <5pref>, <3time>,

make changes

• • •

SPECIAL], <5pref>, <4ID>, <2edit>

• • •

[SPECIAL], <6Punit>

• •

[SPECIAL], <7intern>

• •

[SPECIAL], <7intern>, <3RPT2x> (NOT USED))

• • •

[SPECIAL], <7interrn>, <5log>,

clear log

• • •

[SPECIAL], <8cal>

• •

[SPECIAL], <8cal>, <2edit>

under any selection

• • •

[SPECIAL], <4reset>

• •

[SPECIAL], <4reset>, <4cal>

• • •

[SPECIAL], <4reset>, <5all>

• • •

Remote communications disabled

•

“•” indicates the function/menu is NOT accessible.

OPERATION

RPM4-E-DWT is delivered with no active password and access to the User Level

menu is open. The user level is set to

<1Low>

. User levels can be changed

freely until a password has been created.

To access the LEVEL function

press

[SPECIAL]

,

<5prefs>

,

<5level>

.

The display is:

1change user level

2edit password

Selecting

<1change user level>

brings

up the restriction menu:

Restrictions: 1none

2low 3medium 4high