37

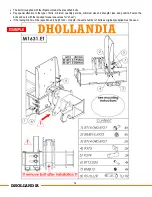

DHOLLANDIA

•

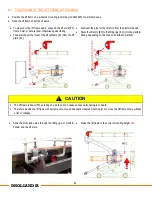

If the forks of the lift cylinders [# 1] have been separated from the lift arms [# 2], operate LIFT / LOWER to align the hole in the

forks [# 1] with the holes in the lift arms [# 2].

•

Mount the pins in same position as originally supplied. Fasten the locking bolts and nuts with required torque.

•

As an alternative, push the piston rod in or pull it out manually, as follows:

1.

Open the safety valves on the lift cylinders manually [see below].

2.

Loosen up the hydraulic couplings of the hoses connected to the cylinder (to eliminate vacuum forces).

3.

Push / pull the piston rod by hand.

Open valve

Close valve

•

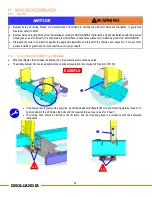

Operate LIFT and pressurize the lift cylinders gently. Stop as soon as you hear the hydraulic system turn in overpressure.

•

If applicable, remove the fitting jigs.

•

Remove the wheeled mounting jack.

Summary of Contents for DH-L 3300 lbs

Page 17: ...16 DHOLLANDIA LMS 55 66...

Page 28: ...27 DHOLLANDIA...

Page 49: ...48 DHOLLANDIA...

Page 52: ...51 DHOLLANDIA 11 3 1 Installation of 3 Button Wander Lead OAE002 E0784 M S...

Page 53: ...52 DHOLLANDIA 11 3 2 Installation of cabin cutoff switch OAE510 15 E0393 S 15...

Page 59: ...58 DHOLLANDIA EF0583 LM EN EF0565 EN EF0620 EN EF0580 EN CAP...

Page 60: ...59 DHOLLANDIA EF0585 US Serial Number EF0581 EN EF0563 EN EF0616 EF0562 EN...

Page 68: ...67 DHOLLANDIA...

Page 69: ...68 DHOLLANDIA...