33

EN

DHOLLANDIA

5.3

5.4

5.5

5.1

5.2

M

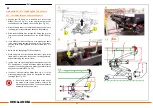

5) MOUNTING OF HTL FRAME UNDER THE CHASSIS

§5.1 - Test fitting lift frame and mounting plates

Position the lift frame on a wheeled jack (order code

M0025) [See 1 on Fig. 5.1], or use a similar device to slide

the frame under the chassis of the vehicle [See Fig. 5.2].

Slide the frame under the chassis, and raise the lift arms to

the fitting jigs (or the articulation hands on the platform).

Slide the articulation pins through the fitting jigs (or plat-

form hands) and the articulations on the lift arm [See fig.

5.3].

If it is difficult to raise the lift arms, or to present the frame

in the correct fitting position [see below & Fig. 5.4], discon-

nect the forks of the cylinders from the lift arms [See 2 in

Fig. 5.1].

Raise it to the fitting height C [See chapter 3].

While doing this, don’t force either side (left or right) of the

frame higher or lower than the position it is taking naturally,

without exercising any special force.

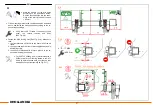

In side view, the mounting plates are designed to put the

HTL frame under 1° upward inclination. Make sure that the

top side of the mounting plates is perfectly parallel with the

body and the chassis [See Fig. 5.4].

In case of bolt-on mounting plates [See Fig. 2.1], fit the

mounting plates over the frame. Do not tighten the nuts at

this stage [See Fig. 5.5].

Do not drill, weld, cut... any parts of the mount-

ing plates or the vehicle chassis, until the full

mounting position of the HTL has been validated

and tested with positive result.

EX.

2

1

!

!