63

DHOLLANDIA

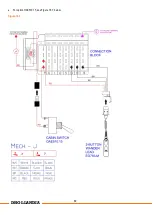

The electrical platform mounted options (flashing lights, foot controls, etc.) function properly.

4 - Inspection of the hydraulic part

There are no visible oil leaks after the load test tests in operation and at rest.

The visible oil level corresponds with the oil level instructions of this manual.

The hydraulic circuits have been purged to remove any remaining air.

During the various movements of the lift, the flexible oil pipes stay clear from the the vehicle chassis & body. They cannot

be damaged by rubbing, squeezing, etc.

None of the thermoplastic pipes has been damaged or marked during welding.

The cover of the pump unit is mounted and securely latched.

5 - Inspection of the platform

The centre point of maximum load is correctly marked and corresponds with the data mentioned on the identification sticker

supplied with the tail lift.

The safe working zone for the operator is clearly and permanently marked on the platform (if applicable). The provided foot

protection conforms with the fitting instructions.

The platform is made sufficiently visible for the surrounding traffic (platform lights, flags, reflective tape, traffic cones).

At vehicle floor level, the platform aligns flush with the extension plate.

A hand grip for the operator to hold when lifting / lowering with the platform, is mounted on the rear frame of the vehicle

body.

7- General operation, practical tests

Unfolding and folding test:

▢

The platform opener is mounted in adequate position. When LOWERED at the ground, the platform stands just inside

from vertical position.

▢

The platform unfolds and folds without touching the vehicle chassis.

General operation with an empty platform: execute all movements several times with ALL available control units. The tail

lift should work smoothly and quietly, and almost silently, through its full range of motion.

▢

Gravity down lifts: during LIFT, only the sound of the running DC motor in the pump unit should be audible.

▢

Power down lifts: the sound of the running DC motor in the pump unit will be audible during LIFT and LOWER

movements.

▢

Any other (creaking, grinding or squeaking) noise should be carefully investigated and solved.

Dynamic test at 100% of maximum rated lift capacity:

▢

Verify if the lift has sufficient lift capacity.

▢

Verify the general performance & stability.

Summary of Contents for DH-LM Series

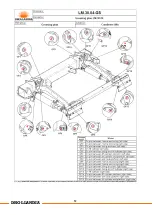

Page 11: ...10 DHOLLANDIA 1 2 9 8 11 2 13 4 7 11 5 v 3 v 10 Figure 6 1 14 6 v...

Page 13: ...12 DHOLLANDIA Figure 6 2 MTG MFT...

Page 27: ...26 DHOLLANDIA Figure 9 6...

Page 34: ...33 DHOLLANDIA Figure 9 15...

Page 42: ...41 DHOLLANDIA EX EX Figure 11 9 Figure 11 10...

Page 46: ...45 DHOLLANDIA Figure 14 1 EX...

Page 50: ...49 DHOLLANDIA Figure 16 2 400mm 400mm 250mm 400mm 400mm 250mm...

Page 52: ...51 DHOLLANDIA EF0583 LM EN EF0565 EN EF0620 EN EF0570 CAP serial nr EF0564 EN EF0581 EN xxxx...

Page 58: ...57 DHOLLANDIA...

Page 59: ...58 DHOLLANDIA...

Page 60: ...59 DHOLLANDIA...

Page 68: ...67 DHOLLANDIA Figure 18 4 Figure 18 5...

Page 70: ...69 DHOLLANDIA For option OAE510 15 see Figure 18 7 below Figure 18 7...