6

DHOLLANDIA

4

SAFETY PRECAUTIONS FOR OPERATION

It is essential that the personnel involved in installing, servicing and repairing tail lifts knows, understands and

applies the safety instructions and precautions contained in the OPERATION MANUAL issued with the tail lift.

Therefore, make sure you consult the OPERATION MANUAL prior to installing or operating the tail lift.

5

SAFETY PRECAUTIONS FOR INSTALLATION

It is essential that the personnel involved in installing, servicing and repairing tail lifts knows, understands and

applies the safety instructions and precautions contained in the GENERAL SAFETY INSTRUCTIONS FOR

INSTALLATION, MAINTENANCE AND REPAIR manual.

Therefore, make sure you consult the GENERAL SAFETY INSTRUCTIONS FOR INSTALLATION,

MAINTENANCE AND REPAIR manual prior to installing the tail lift.

These instructions are supplied as a separate manual with your tail lift.

You can also contact your national DHOLLANDIA distributor for the latest edition of this manual. See page 5 for

contact info. Or download the latest edition from the website:

www.dhollandia.com → your language → Downloads → User’s manuals → General information

WARNING

Improper use of the tail lift will put the operator and other parties at great risk of serious bodily injury and death.

To reduce the risk of serious bodily injury to the operator and any bystanders, the use of the tail lift is restricted to skilled

operators, who have been properly trained, and who know and understand the full contents of the operation manual.

To reduce the risk of serious bodily injury or death, THE OPERATOR MUST COMPLY WITH ALL SAFETY INSTRUCTIONS

AND WARNING LABELS IN THE OPERATION MANUAL before and while operating the tail lift.

Please confirm you have reviewed the most up-to-date version of this manual prior to installation and operation of the associated

DHOLLANDIA tail lift.

Summary of Contents for DH-LM Series

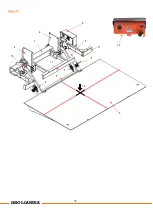

Page 11: ...10 DHOLLANDIA 1 2 9 8 11 2 13 4 7 11 5 v 3 v 10 Figure 6 1 14 6 v...

Page 13: ...12 DHOLLANDIA Figure 6 2 MTG MFT...

Page 27: ...26 DHOLLANDIA Figure 9 6...

Page 34: ...33 DHOLLANDIA Figure 9 15...

Page 42: ...41 DHOLLANDIA EX EX Figure 11 9 Figure 11 10...

Page 46: ...45 DHOLLANDIA Figure 14 1 EX...

Page 50: ...49 DHOLLANDIA Figure 16 2 400mm 400mm 250mm 400mm 400mm 250mm...

Page 52: ...51 DHOLLANDIA EF0583 LM EN EF0565 EN EF0620 EN EF0570 CAP serial nr EF0564 EN EF0581 EN xxxx...

Page 58: ...57 DHOLLANDIA...

Page 59: ...58 DHOLLANDIA...

Page 60: ...59 DHOLLANDIA...

Page 68: ...67 DHOLLANDIA Figure 18 4 Figure 18 5...

Page 70: ...69 DHOLLANDIA For option OAE510 15 see Figure 18 7 below Figure 18 7...