38

DHOLLANDIA

11

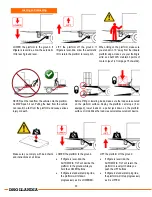

MEANING OF SAFETY AND WARNING SIGNS

WARNING signs

Overview and keep visual control over the working

area of the liftgate at all times.

General warning sign used to alert the user to

potential hazards. All messages that follow this

sign shall be obeyed to avoid possible harm.

Entrapment hazard. Keep hands, limbs, loose

clothes and long hair away from moving parts.

Crushing & shearing hazard. Keep hands away

from moving parts.

Crushing & shearing hazard. Keep feet away from

moving parts.

Slipping hazard.

Tripping hazard.

Hazard caused by tilting objects.

Hazard of falling from heights.

MANDATORY ACTION signs

Contact your regional DHOLLANDIA distributor.

Consult the DHOLLANDIA website.

Download from DHOLLANDIA website.

Read the manual or instructions.

Hold onto safety rail. Protect yourself from falling

off the platform, or vehicle floor.

Wear safety gloves.

Wear safety-toe shoes.

Wear appropriate work clothes, avoid loose-fitting

clothes that might be trapped in the moving parts

of the lift.

Wear safety protection, eye protection and a

safety hard hat.

Use a safety shield.

PROHIBITION signs

General prohibition. DO NOT do!

DO NOT use machine by more than 1 operator!

General prohibition. DO NOT do!

DO NOT step or stand here!