REV. H 10/12

9

E.

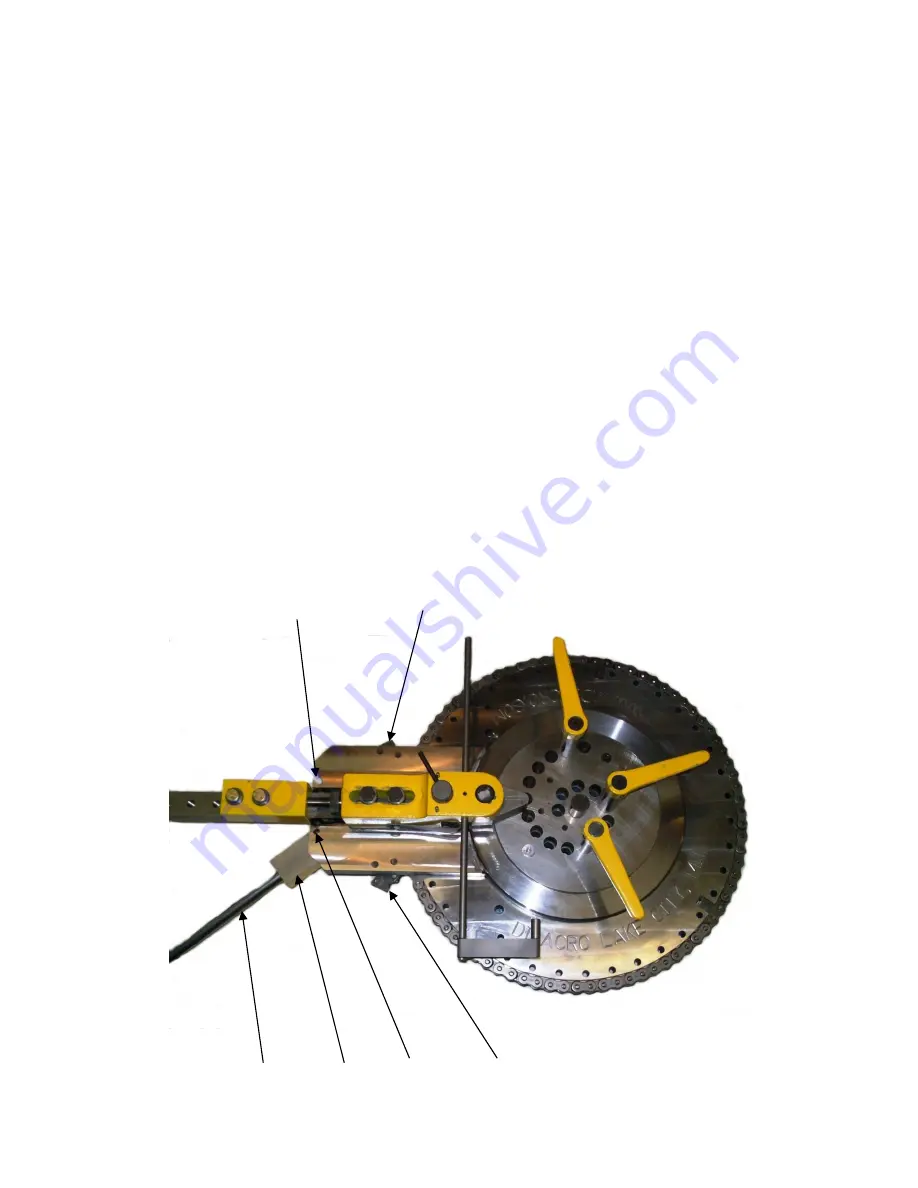

RATCHET AND DIRECT OPERATION

RATCHET OPERATION

For clockwise operation of the Di-Acro No. 4 Bender, engage check

pawl (B) and disengage check pawl (C). Remove stop pin (F) from hole

(D) and place in hole (E). For counter-clockwise operation, engage

check pawl (C) and disengage check pawl (B). Remove stop pin (F)

from hole (E) and place in hole (D).

*CAUTION*

STOP PINS MUST BE USED AS DESCRIBED ABOVE WHEN USING

THE RATCHET MECHANISM. FAILURE TO DO SO CAN RESULT IN

SERIOUS BODILY INJURY.

DIRECT OPERATION

For direct drive operation without the ratchet, disengage both check

pawls (B) and (C). Remove handle (H), place handle holder (I) in

neutral position between holes (D) and (E). Insert stop pins into both

holes.

E-F

C

H I D B