JINDLE04 Rev B 15/09/15

C

LEARANCES TO

C

OMBUSTIBLE

M

ATERIALS

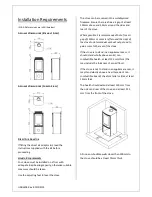

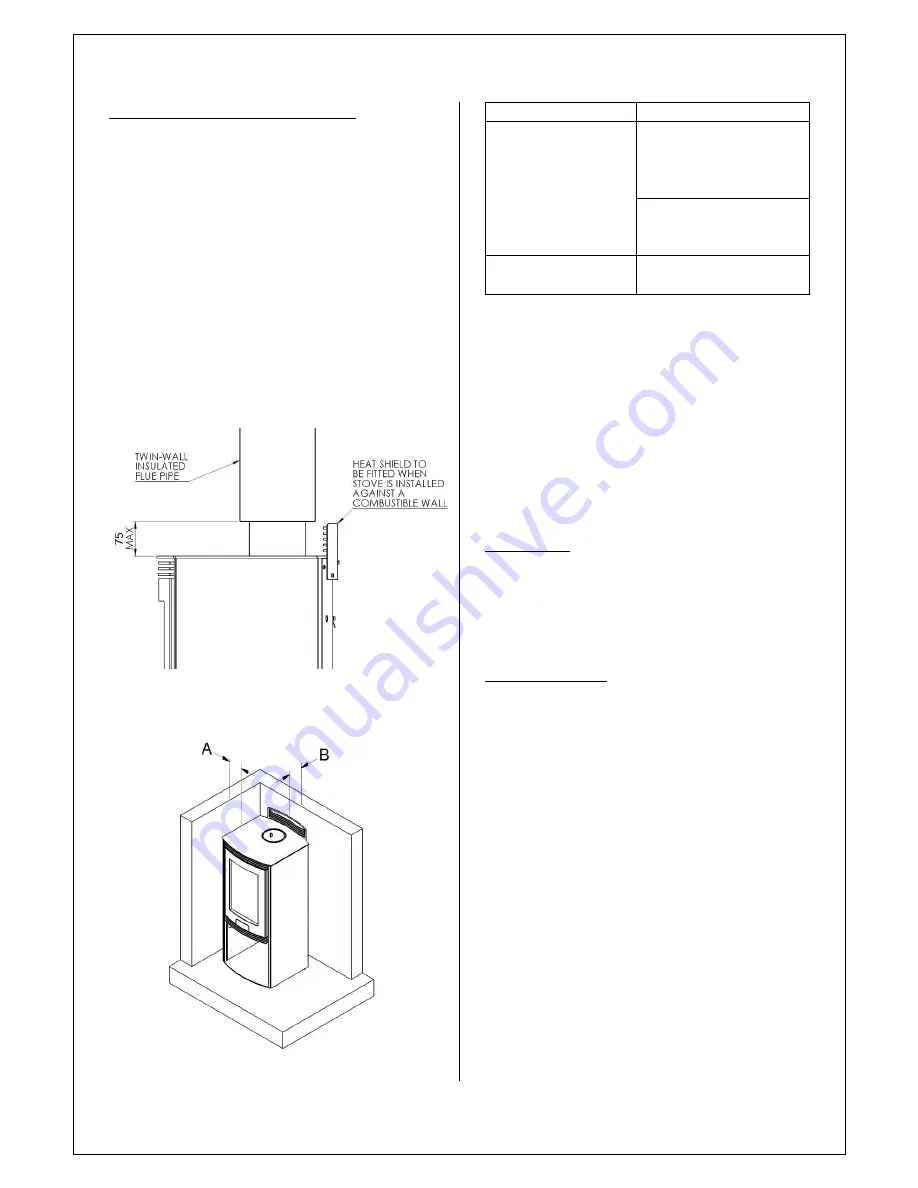

Note: combustible material refers to any material

that will degrade when subjected to heat e.g.

plaster.

For distances to combustible materials, see table

below. No combustible furniture should be placed

any closer than 900mm from the front of the

stove.

Note: To achieve the specified distances to

combustible materials, twin-wall insulated flue

pipe must be used, starting no higher than 75mm

above the stove.

D

ISTANCES TO COMBUSTIBLE MATERIALS

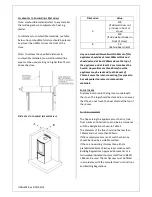

Dimension

Value

A

100

(If side wall does not

protrude in front of

stove)

300

(If side wall protrudes in

front of stove)

B

50

(Behind heat shield)

Any non-combustible walls within 50mm of this

appliance should be at least 200mm thick and

should extend at least 300mm above the top of

the appliance and at least 1.2 metres above the

hearth. Any walls more than 50mm from the

appliance may be reduced to a thickness of

75mm. Ensure the inter-connecting flue pipe also

has adequate clearances to combustible

materials.

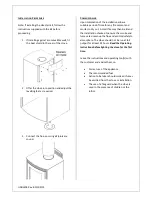

F

UEL

S

TORAGE

Fuel may be stored in the log recess underneath

the stove. The logs should be stacked in such a way

that they do not touch the heat shield at the top of

the recess.

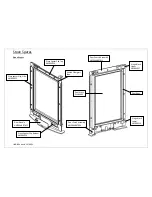

F

LUE

R

EQUIREMENTS

The flue serving this appliance must be dry, free

from cracks and obstructions and be in accordance

with the designations shown in Table 1.

The diameter of the flue should not be less than

150mm and not more than 200mm.

If these requirements are not met the chimney

should be lined by a suitable method.

If there is no existing chimney then either a

prefabricated block chimney in accordance with

Building Regulations Approved Document J or a

twin-walled insulated stainless steel flue to BS EN

1856 can be used. These chimneys must be fitted

in accordance with the manufacturer’s instructions

and Building Regulations.