OPERATION AND MAINTENANCE (CONT.)

12. Method for replacing the brush disk

A. Installation of the brush pad: Put the brush pad under

its cover (If the dial is used, the brush pad should be

installed on the dial, then put the brush pad under its

cover.) Lay down the brush pedal and align the brush

head with the brush clip. Then press, the brush disk will

be installed automatically with the running of the motor.

And then you can carry out your operation as usual.

B. Removal of the brush pad: There are two ways to

remove the brush pad:

The first way is to step on the brush pedal after the work

(Uplift the brush pad), then turn off the brush switch. At

this time, the brush pad will be removed automatically

after the motor stops running. The second way is to

press, and then the brush pad should be removed auto-

matically in the condition that the brush pedal is stepped

on.

13. Method for replacing the batteries

n

turn off all the switches, lift off the dirty water tank

(see figure11)

n

loosen the strap of the batteries, discharge the

connecting cables, replace the batteries separately.

14. Maintenance of the squeegee

As a major component of the machine, the squeegee

will be worn away due to friction between the glue bars

and the ground during operation. In case it is not effec

-

tive, the following procedures should be conducted:

A. Check whether there is anything in the rubber scraper;

(Prepare a towel to wipe the dirty rubber blade at any

time)

B. Check whether the joint of the squeegee and hose is

clogged up by the small pieces. (Remove the connection

of hose or squeegee to clean the clog.)

C. Check whether the angle between the scraper and

ground is proper; if not, you can adjust the angle by

regulating the hand wheel. (Seen in figure8)

D. Check the wearing condition of the scraper edge. If the

wearing condition is so serious that the adjustment will

not work, turn over the rubber blade and use another

side of it. (see figure 12) If another side is also worn out,

it has to be replaced by new rubber blade.

Note: If the brush pad is in the process of being

raised, the brush motor should not be started up

arbitrarily; otherwise, the brush disk will be

removed automatically.

Figure 12

15.Daily upkeep when operation is finished:

n

clean the machine surface with a wet and dry cloth, and

open the water tank cover to check and make sure there

is no damage with the inside seal.

n

pumping out the dirty water from the pollution tank,then

add more clean water to wash the inside again.

n

uplift the brush and the squeegee, pack the machine in

a dry, flat place without combustible gas, combustible

liquid, chemicals, or fire.

n

if unused for a period of time, please disassemble the

battery from the machine and clean the tanks. Cover the

opening of the tank cover with a dust cloth.

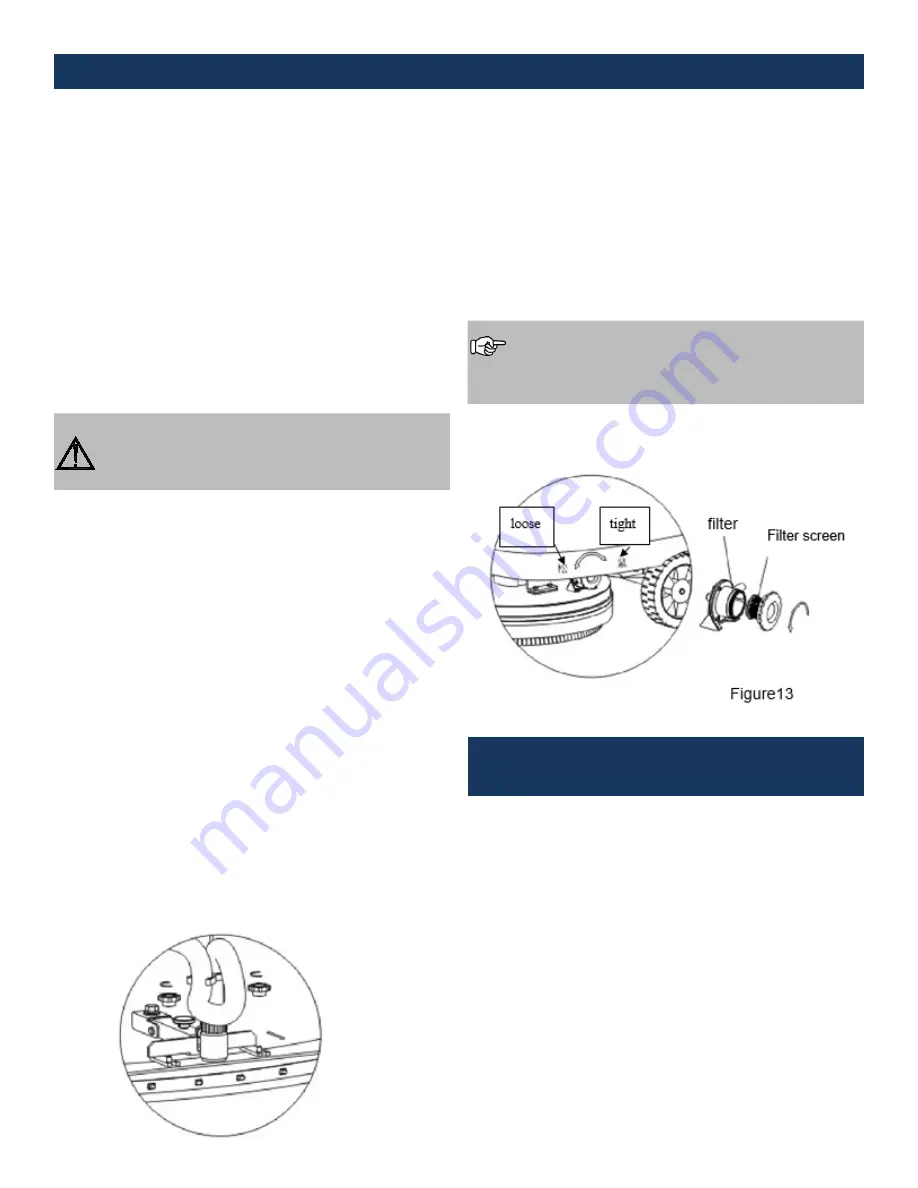

16.Ensure the clean water tank is clean. Cumulation may

cause a blockage. Clean the filter weekly to ensure the

water pipe expedite when in operation (see figure 13)

For the battery, you should keep charging as per the

instruction in the clause <battery maintenance and

charging> even though the battery is disassembled

from the machine.

MAINTENANCE AND CHARGE

OF BATTERY

This machine is battery-powered and thus the quality of

the battery will directly affect the function of the machine.

Please use the battery recommended by our company or

other high-quality power batteries.

(Never use any automotive battery.)

In order to adapt itself to the requirements of various work-

ing conditions, battery 12V×2/100AH can be used in this

machine. Please choose proper batteries according to your

demands. Except for the difference in capacity, the batter

-

ies can be classified in two main categories: maintenance

battery and maintenance-free battery according to their

nature.

As an open type battery, a great deal of vapor bubbles

will be produced when charging the maintenance battery.

Therefore, the battery chamber cover should be taken off

every time it is being charged. The liquid height of the

electrolyte should be often checked. If it is lower than a

specified height, distilled water should be added in time.