Method: Take the waste pipe out of the clip, open the

cap of the tube, discharge sewage to the sewer and

clean the recovery tank.

(Seen in figure 9)

B. If the water level of the recovery tank is not too high and

it’s not bubbling, the connection between squeegee and

hose should be checked for clogs. In this case, the wa-

ter sucker will recover normal after being cleaned.

C. If the water level of recovery tank is not so high but

it is bubbling too much, that indicates that excessive

cleansers have been added or the cleanser you used

is a bubble-productive one. The water absorption motor

recovers only after enough bubble-dispelling agents are

put into the recovery tank.

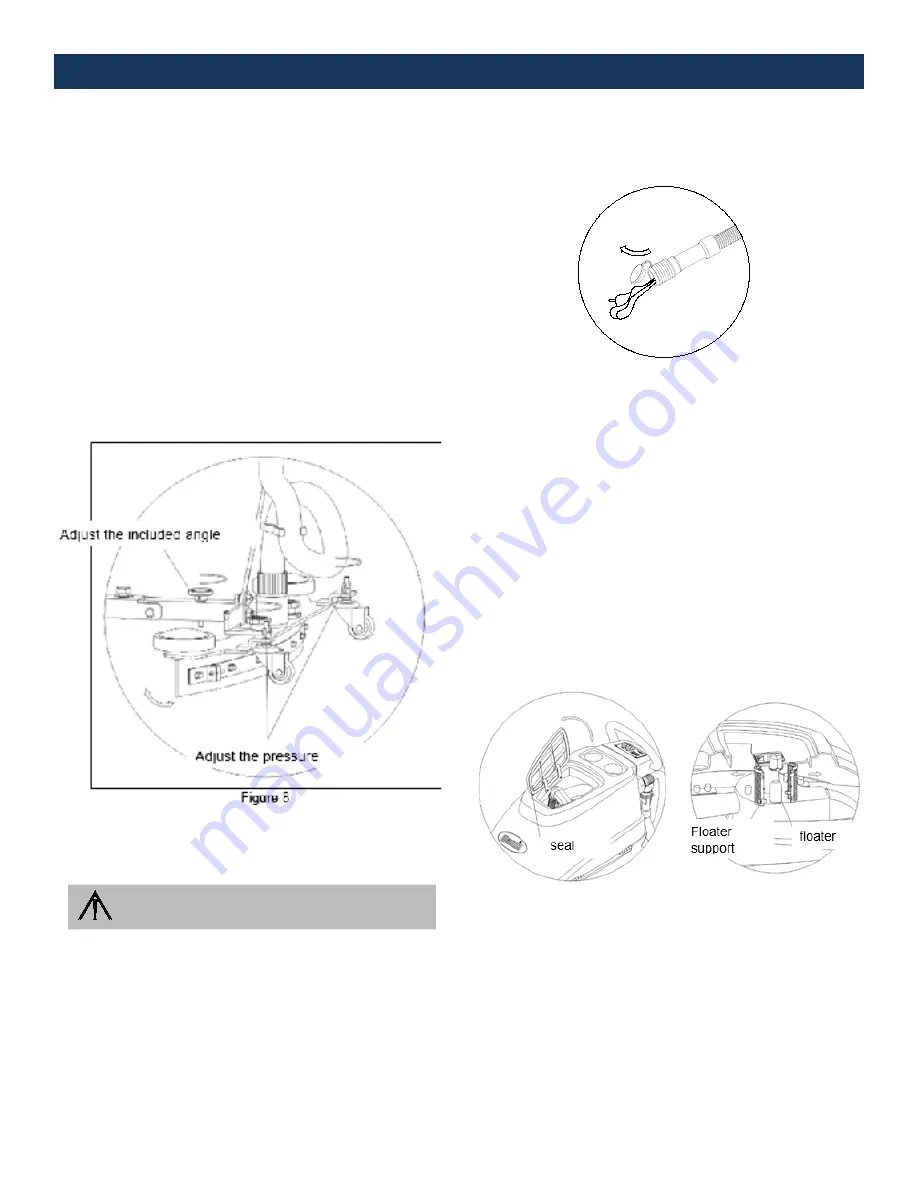

D. Remove the upper cover (see in figure 10), start up the

suction motor, and make sure that the suction intake is

normal. If the suction is too weak, check the seal and

whether the floater is jammed (Seen in figure 10).

8. With the regulating handle of squeegee, increase or de-

crease the angle between the squeegee and the floor.

The suction of dirt would be efficient with a suitable

included angle.(see figure8)

9. Regulating the pressure between the squeegee and the

floor

n

screw the small casters up to keep them from

touching the floor when the squeegee is working,

then adjust the included angle between the squee

-

gee and floor to have the best working status for the

squeegee.(the included angle is 90° between the

rubber blade and floor).

n

screwing the casters down keeps them on the floor

when the squeegee working. Keep adjusting the

casters until the squeegee is working efficiency.

n

screw the casters up a bit, to give the squeegee the

best working efficiency (see figure 8).

10. If there is still cumulation after one way cleaning on a

rough floor, just lift up the squeegee and switch on the

suction motor, repeat the sucking in that area.

11.Problems occurred while adjusting the water suction.

During the operation, you should stop the machine and

check it immediately if the suction motor sounds abnor-

mal, or if the squeegee can not suck or absorb water at

all.

A. When the water level rises to the highest point (the

bobber can touch the cap), the sewage should be dis

-

charged.

OPERATION AND MAINTENANCE (CONT.)

Deep grooves may cause incomplete cleaning,

please dispose separately.

Figure 9