AIRCRAFT

DA 40 Series AMM

Temporary Revision

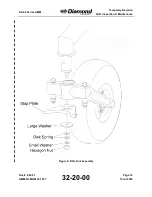

NLG Inspection & Maintenance

100 hr items marked X* apply to US registered airplanes only

Inspection Items

100 200 1000 2000 Time Initials

31.

Examine the elastomeric spring. Look specially for:

Looseness. Tighten if necessary. (Refer to Section

32-20).

Damage. Replace elastomer donuts if necessary.

(Refer to Section 32-20).

X

X

X

X

32.

Examine the elastomer pack center tube:

Remove the elastomer pack (refer to Section 32-20)

Remove the elastomer elements (refer to Section

32-20).

Remove the elastomer pack center tube:

If the center tube shows signs of deformation:

Replace the center tube (refer to Section 32-20).

If the center tube shows signs of wear:

Replace the center tube if a radial wear limit

(depth measured) of 0.8 mm is exceeded.

Remove the elastomer elements in the event that

they are worn or cracks are found. (Refer to Section

32-20).

Adjustment and installation of the elastomer pack

(refer to Section 32-20).

X

33.

Remove the NLG fork (Refer to Chapter 32-20)

. Inspect

the fork for cracks, corrosion and deformation. Look

specially on the legs and filleted areas.

X

X

X

X

34.

Inspect the nose landing gear fork collar bushings.

X

X

X

X

35.

Inspect the NLG leg for cracks, corrosion and damage.

Use a flashlight and a 10X magnifier. Pay special

attention to the pivot axle (especially the radius at the

top), filleted areas, and the threads at the bottom of the

fork pivot axle. If cracks are suspected, perform NDT.

X

X

X

X

36.

Inspect the stop plate for cracks and damage.

X

X

X

X

Doc # 6.02.01

AMM-TR-MÄM 40-1037

05-28-50

Page 7

13 Jul 2020