2

INTRODUCTION

This manual will help you get the most from your

Cobra-H-DLC.

Read these instructions thoroughly

before operating the machine.

This product is intended for commercial use only.

PARTS AND SERVICE

Repairs, when required, should be performed by your authorized Diamond Lustre dealer who maintains

an inventory of original replacement parts and accessories.

Call the Diamond Lustre distributor from whom you purchased your machine when you need parts or

service. Please specify the Model and Serial Number when discussing your machine.

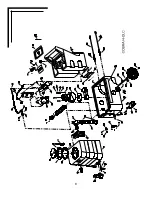

SERIAL NUMBER PLATE

The Serial Number of your machine is shown on the plate that is mounted on the floor of the base

compartment. This serial number and model are needed when ordering replacement parts for the machine.

Use the space below to note the Model and Serial Number of your machine for future reference.

MODEL : COBRA-H-DLC

SERIAL NUMBER : _____________________________________

Be sure to fill out and return your warranty card.

DO NOT OPERATE THE MACHINE UNTIL YOU HAVE READ THIS SECTION.

IMPROPER USE WILL VOID THE WARRANTY.

•

Always use a defoamer when foaming occurs to prevent vacuum motor damage.

•

Never use water above 130

°

F (54

°

C).

•

Do not use outdoors or where temperature is below freezing. Protect your machine from any

extremes in temperatures.

•

Do not let the pump run dry. Turn the pump off and refill the tank when cleaning solution

gets low.

•

Flush the machine with an acid de-scaler regularly (monthly or more often) to prevent a

build-up of minerals or chemicals in the pump and heat systems. Follow the flush with a clear

water rinse to remove any particles and to rinse the acid from the machine.

•

Use approved chemicals only. All chemicals should be mixed thoroughly. Liquid chemicals

are recommended to prevent powder buildups. A pH between 6 and 9 is recommended.

The use of high alkaline detergents or strong acids will accelerate the wear of the pump

and seals, and will void the warranty.

•

All extension cords must have a rating of at least 12/3 (#12 cord). Extension cords should

be no longer than 50 feet. Replace the plug immediately if the ground prong becomes

damaged or is broken off.

UNCRATING

When the machine is delivered, carefully inspect the shipping carton and the machine for damage. If damage is

evident, save the shipping carton so that it can be inspected. Contact Diamond Lustre Customer Service

immediately for instructions on how to file a freight damage claim.

Summary of Contents for COBRA-H-DLC

Page 1: ...1 COBRA H DLC 09 2003 COBRA H DLC OPERATOR S MANUAL ...

Page 8: ...8 ...