MAINTENANCE

CONTINUED ON NEXT PAGE

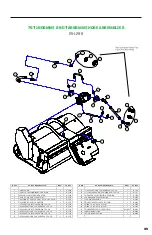

Bearing Maintenance:

•

Clean any oil or debris off the

surface of the insert where the end

cap will mate

(4)

.

•

Remove the cap screws.

◦

NOTE:

Failure to remove excess

oil from the holes may result in a

cracked insert when the end cap

is secured to the insert.

•

Place the end cap upside down on

the work surface and clean any oil

or debris off of the grooved surface

where the insert will mate to

(4)

.

◦

Place a dot of RTV silicone

sealant

(12)

on the groove between

each hole.

◦

Place the O-ring

(13)

into the

groove on the end cap.

•

Place the end cap onto the ground

insert without dislodging the O-ring

from its groove

(14)

.

•

Secure the end cap to the insert

with the cap screws

(14)

.

◦

Tighten the cap screws evenly in

a criss-cross pattern.

◦

Torque the cap screws to

29ft-lbs (39Nm).

◦

Make sure the plug hole is not

blocked to allow air to escape.

•

Wrap the 1/8” NPT plug

(15)

with teflon

tape and thread it into the plug hole

on the end cap.

◦

Tighten until snug.

(12)

(13)

(15)

(14)

22