OPERATING

Blade Speed

Refer to the CC3538JK RPM Chart, the blade,

or the blade packaging information for the

recommended blade speeds when cutting. DO

NOT exceed the maximum recommended

blade speed. DO NOT use a blade for cutting

that requires a lower speed than the minimum

blade shaft speed.

Wrench

Use the wrench provided when installing or

removing a blade. Apply force to the opposite

end of the wrench and tighten the blade shaft

bolt/screw to 125 ft-lb (169.5 Nm) to secure the

outer flange and blade. Verify this

measurement with a torque wrench.

Wrench

Installing the Blade

WARNING

•

DO NOT install a blade with

the engine running.

•

Failure to properly secure the

outer flange and blade may cause parts

to loosen or fall off the saw, resulting in

serious injuries or death!

•

DO NOT pivot the front of the blade

guard up or down when installing very

large blades. Attempting to pivot the

front of a heavy guard when the guard

is positioned higher up for blade

installation makes the guard difficult to

lift and/or lower. In this situation,

remove the blade guard front instead of

pivoting it.

•

Always secure the pivoted section of

the blade guard using the detent pin

(guards 26” and up).

CAUTION

•

Wear gloves and be alert to the

surrounding environment when

handling blades.

The blade can be installed on the right or left

side of the saw. Install the blade on the side

preferred or most appropriate for the cutting

task.

1.

Select a blade size and type. Remember to

check the blade for damages and discard

as necessary.

Note: If changing the blade size, adjust and/or

change all necessary saw components

according to the information in the CC3500J

Parts List.

2.

Remove the detent pin (guards 26” and up)

from the guard hinge and pivot the front of

the blade guard 180° (fully upward) to gain

access to the blade flanges.

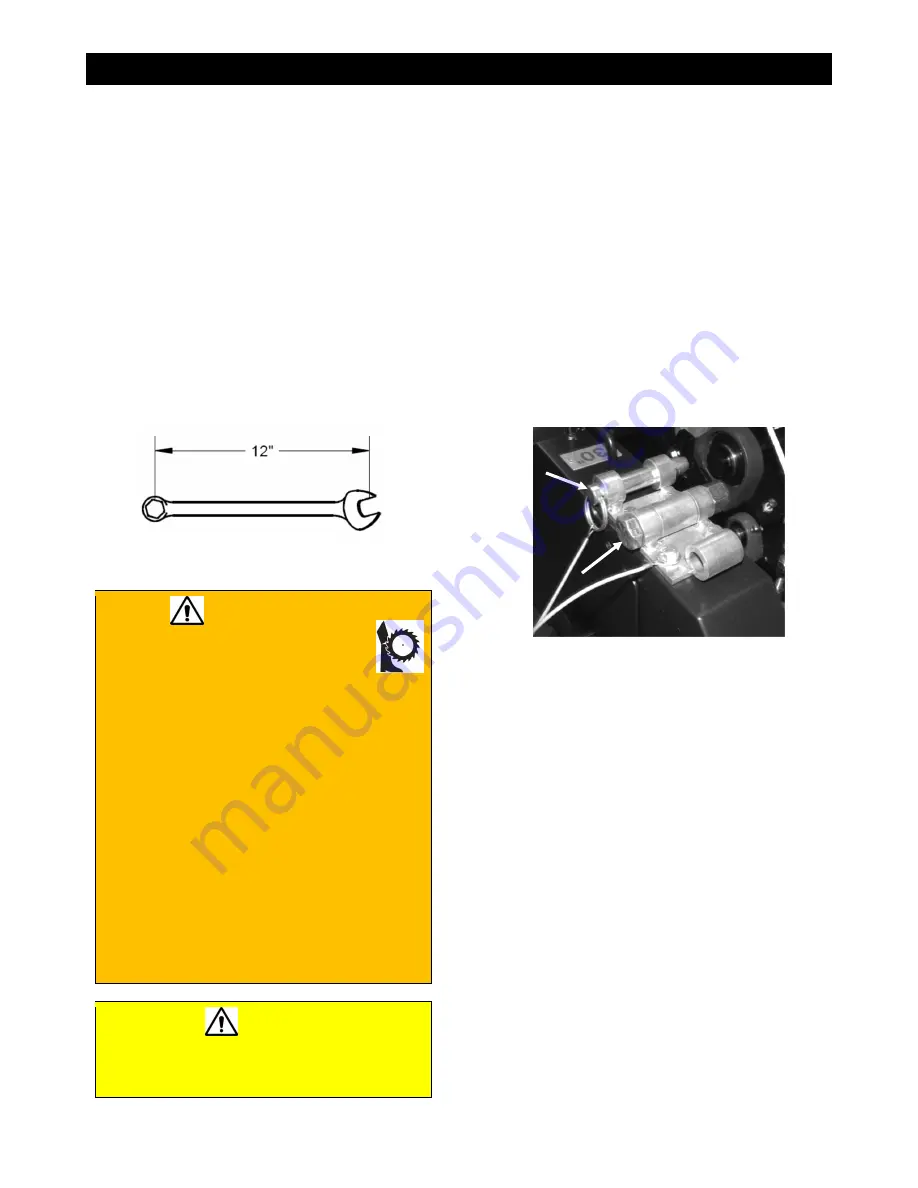

Detent Pin and Hinge Screw

3.

On pivoted guards, insert the detent pin

through the interlocking barrels on the top

of the guard to secure the front of the

guard.

Note: Failure to fully pivot and secure the front

of the guard may cause serious injuries.

4. Remove the blade shaft screw (clockwise

loosens on right side, counterclockwise

loosens on left side) using the wrench.

5. Carefully remove the outer flange. Inspect

the flange assembly and clean or replace

dirty/damaged components.

6. Place the blade against the inner flange.

For large blades, carefully roll the blade up

to the inner flange. Adjust the height of the

saw to align the flange and blade arbor.

Note: Point the arrow printed on the blade in

the direction of the blade shaft’s rotation.

7.

Align and fit the outer flange and flange pin

through the blade and into the inner flange

and blade shaft.

18

Summary of Contents for CC3538JK Series

Page 1: ...CORE CUT OPERATOR S MANUAL CC3538JK Electronic Fuel Injection May 2020 Rev 20 00 Part 1802723...

Page 2: ......

Page 47: ...REFERENCES 47...

Page 48: ...REFERENCES 48...

Page 49: ...REFERENCES 49...

Page 51: ...REFERENCES...