MAINTENANCE

Yearly Service

Replace and Gap Spark Plugs

There are two spark plugs associated with the

engine. One in the front of the saw directly

below the oil fill cap, and one directly opposite

of the first between the engine and the upright

assembly.

•

Refer to the engine operator’s manual for

all spark plug specifications.

•

Ensure the engine is turned off and

sufficiently cooled down prior to replacing

the spark plugs.

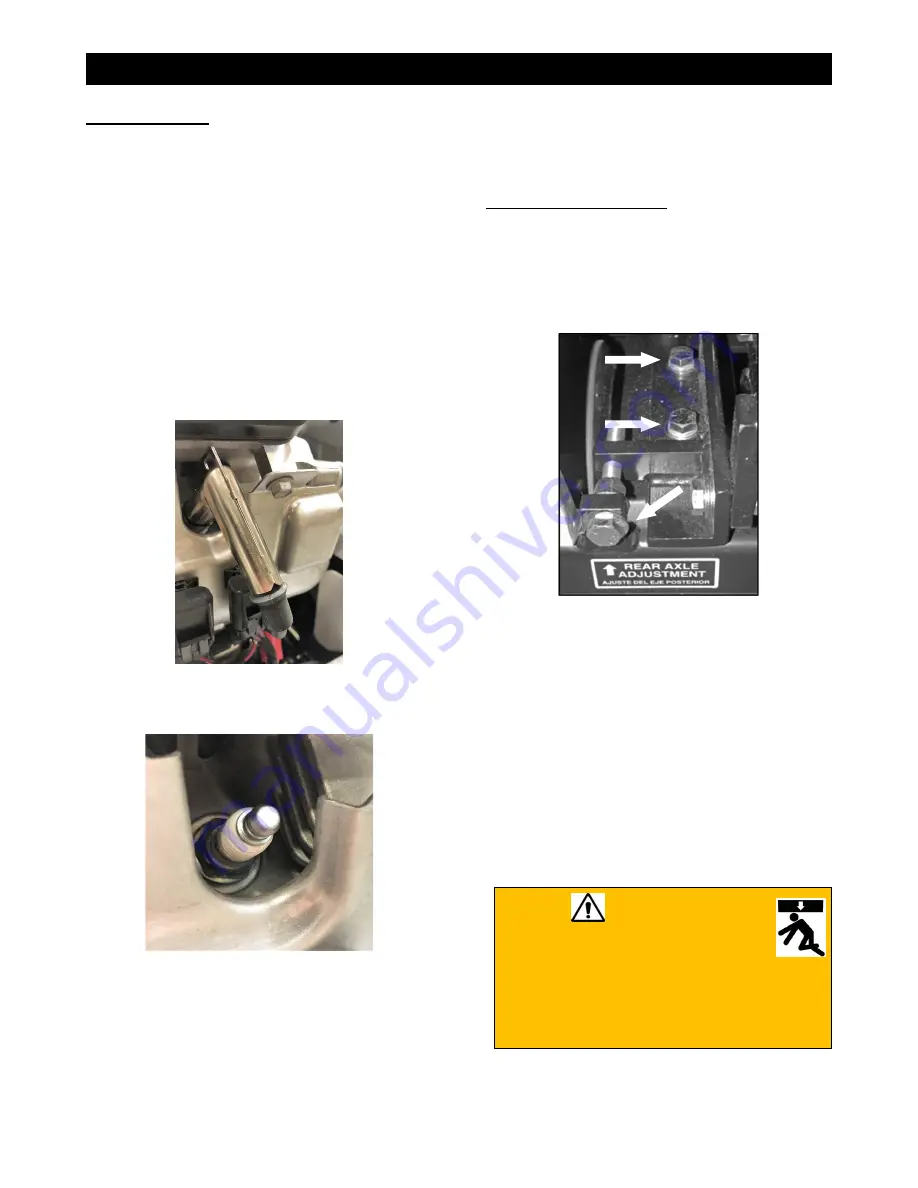

1. Pull the spark plug wire (with a metal cap)

away from the spark plug.

Spark Plug Wire with Metal Cap

2. Remove the spark plug using a 5/8” spark

plug socket.

Spark Plug

3. Gap the new spark plug in accordance with

the engine manufacturer’s specifications.

4. Install the new plug and torque it in

accordance with the engine manufacturer’s

specifications.

5. Reinstall the plug wire ensuring that it is

fully seated onto the plug.

6. Repeat steps 1 through 5 for the second

plug.

Regular Maintenance

Drive Alignment

Adjust the rear axle when the saw’s drive

alignment is off (saw will not cut in a straight

line).

Note: The rear axle can be adjusted

based on preference

.

Rear Axle Bearing Bolts and Adjustment Bolt

1. Loosen the two left rear axle bearing

screws.

2. Loosen the hex nut on the rear axle

adjustment bolt.

3. Turn the adjustment bolt clockwise to

adjust the drive alignment toward the left,

or counterclockwise to adjust the drive

alignment toward the right.

4. Retighten the hex nut on the adjustment

bolt.

5. Retighten the two left rear axle bearing

screws.

Wheels

WARNING

Raise the saw to a proper height

for access when working

underneath the saw. Use chocks to block

the wheels, and fit blocks or jacks under

the frame edges at the front and back of

the frame for additional support.

36

Summary of Contents for CC3538JK Series

Page 1: ...CORE CUT OPERATOR S MANUAL CC3538JK Electronic Fuel Injection May 2020 Rev 20 00 Part 1802723...

Page 2: ......

Page 47: ...REFERENCES 47...

Page 48: ...REFERENCES 48...

Page 49: ...REFERENCES 49...

Page 51: ...REFERENCES...