MACHINE SET UP &INSTALLATION

UNCRATING MACHINE

Be sure and check packing carton for any damage.

Immediately report any damage to carrier. Check

contents of package to ensure that the following

items are included: Machine, batteries (x2),

squeegee assembly, battery charger, and pad driver.

BATTERY CONNECTIONS

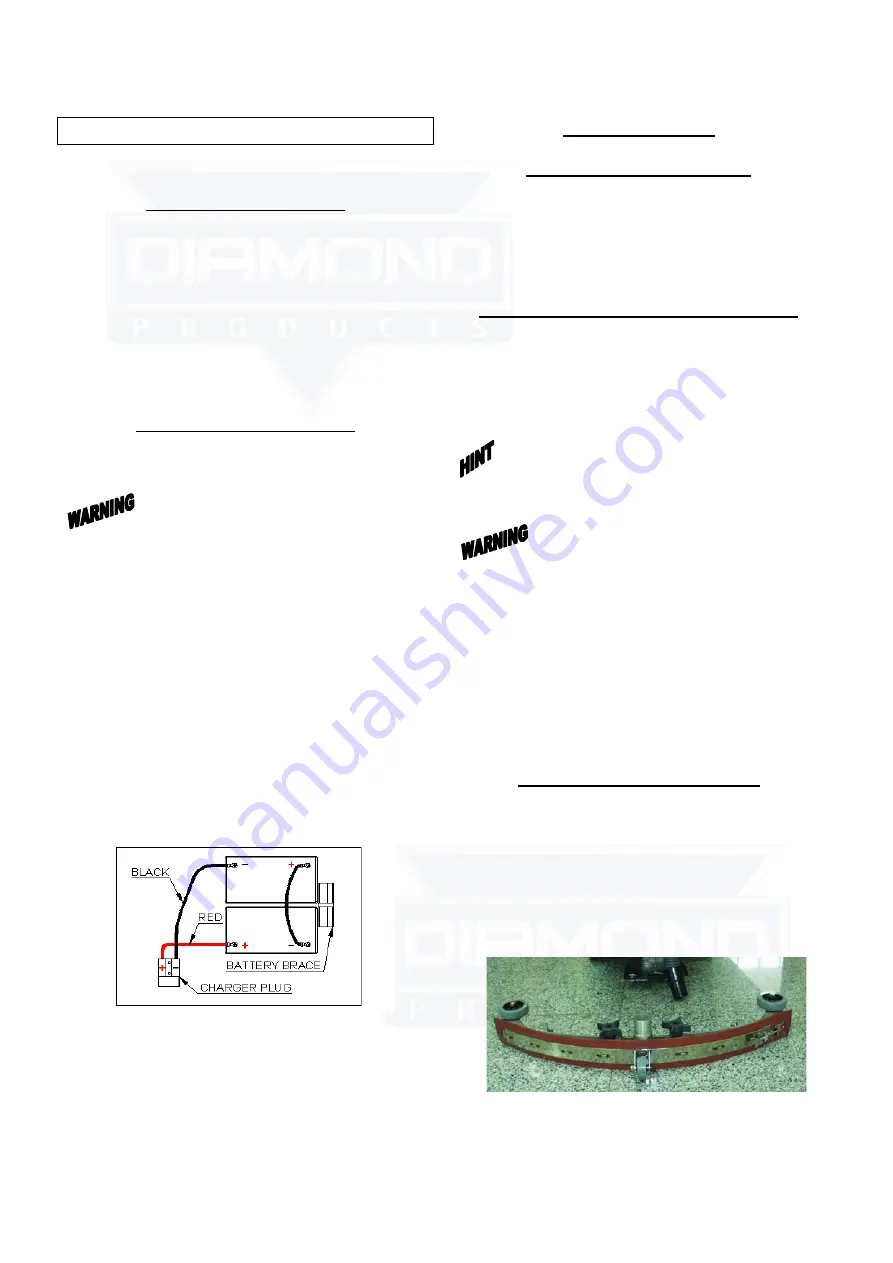

The batteries are already in the machine upon

delivery; however, you will need to connect the

cables to the battery posts.

: Batteries emit hydrogen gas.

Explosion or fire can result from hydrogen gas.

Keep sparks and open flames away! Keep battery

compartment open when charging.

1. Be sure power switch is in the “off” position.

2. Open recovery tank to gain access to battery

compartment.

3. Carefully place the two batteries into the

compartment as shown in figure below. Place

the battery brace at the rear of the two batteries.

DO NOT DROP BATTERIES INTO

COMPARTMENT!

4. Connect battery cables to posts in numbered

order as shown in drawing below. (RED to

POSITIVE and BLACK to NEGATIVE)

5. Apply a coat or protective spray on the cable

connections to prevent battery corrosion.

MACHINE SET UP

PRE-OPERATION CHECKS

1. Sweep or dust mop the surface to be cleaned.

2. Check battery meter to make sure batteries are

fully charged. (see BATTERY CHARGING)

3. Check that squeegee is properly installed.

4. Check that brush / pad is properly installed.

INSTALLING PAD DRIVER OR BRUSH

1. Ensure that the machine is turned off

2. Lower brush head assembly to the floor by

stepping on the foot pedal and pushing pedal

forward.

3. Tilt the machine backward to access the drive

motor hub.

: Remove the squeegee assembly prior to

tilting the machine backwards. It makes the

process faster and easier.

: Do not keep the machine tilted back for

a long time. This could cause battery acid to leak

from the batteries.

4. If using a pad driver, first attach the

appropriate pad to the pad driver surface.

5. Mount the pad driver or brush to the drive

motor hub by lining up the three studs with the

three holes in the drive motor hub. Once in the

holes, rotate the driver toward the spring clip

to lock driver into place.

MOUNTING THE SQUEEGEE

1. Pull back on the squeegee lift lever to raise the

squeegee bracket up.

2. Loosen the two knobs on the squeegee and

slide the squeegee into the slots at the rear of

the squeegee bracket. (the wheels on the

squeegee point to the back)

3. Tighten the knobs securely.

.

-5-

Operator's Manual

Diamond Products

Summary of Contents for CROWN G20

Page 11: ...3b_g 7 11 Operator s Manual Diamond Products...

Page 13: ...3b_g 7C 13 Operator s Manual Diamond Products...

Page 15: ...3B G 7 7C 15 Operator s Manual Diamond Products...

Page 17: ...3B G 7 7C 17 Operator s Manual Diamond Products...

Page 19: ...3B G 7 7C 19 Operator s Manual Diamond Products...

Page 21: ...3B G 7 21 Operator s Manual Diamond Products...

Page 23: ...3B G 7 7C 23 Operator s Manual Diamond Products...

Page 25: ...3B G 7C 25 Operator s Manual Diamond Products...

Page 27: ...3B G 7 7C 27 Operator s Manual Diamond Products...

Page 29: ...3B G 7 7C 29 Operator s Manual Diamond Products...

Page 31: ...3B G 7C 31 Operator s Manual Diamond Products...