16

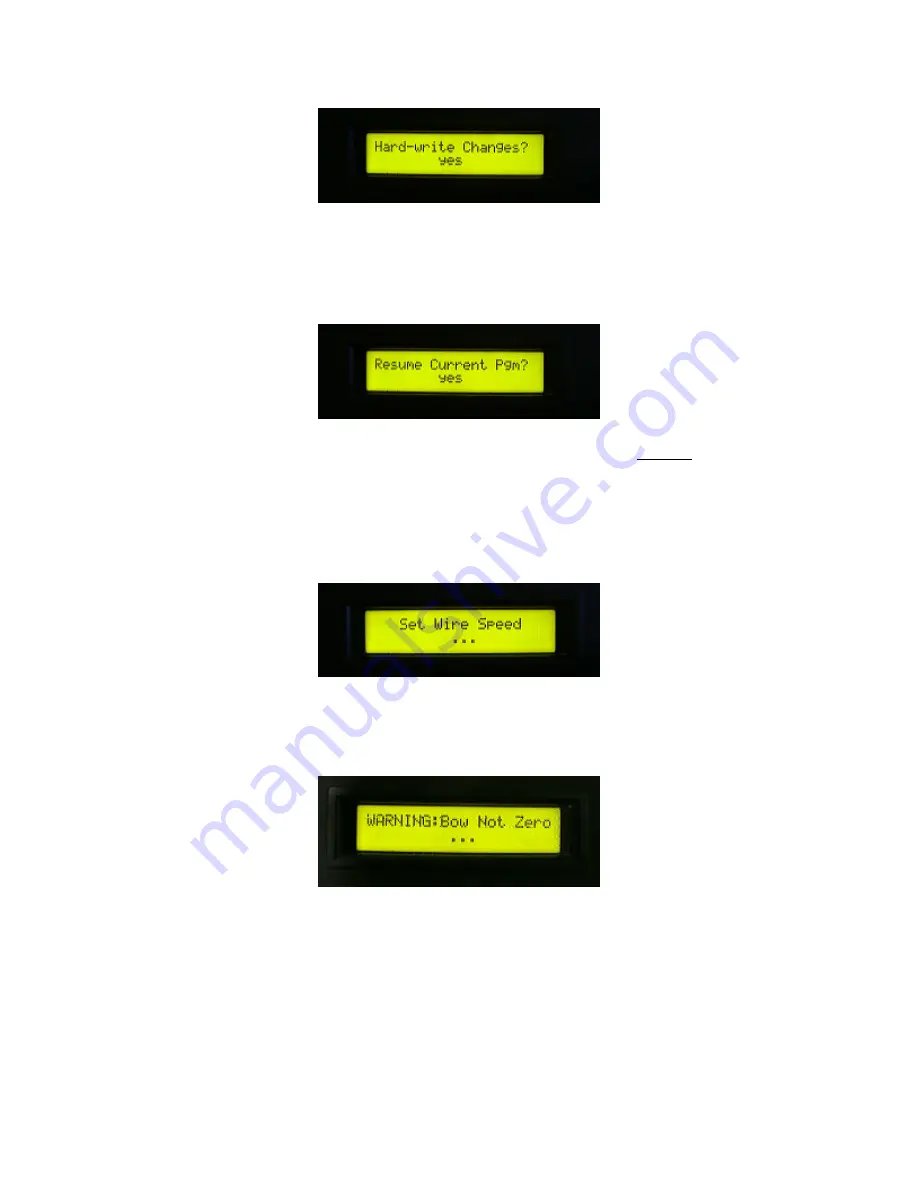

19. This question is asked if any program parameters have changed. Answer “yes” if you want the

operating parameters just specified to be stored in non-volatile EEPROM memory so that they are

“remembered” even if power is turned off. Answer “no” if you want to perform a cut program

using the parameters you just specified without overwriting those stored in EEPROM.

20. In normal operation you will not see this screen and will go directly to Step 21. If however, you

interrupted a cut program in progress, or if there was a wire break during an automatic cut program,

you are asked if you want to resume the interrupted cut program or begin anew. If you jog the yoke

up or down before resuming an interrupted program, the control software compensates and still

considers your programmed cut depth as the end of cut indicator. This allows you to resume back at

the start of the current cut, exactly where it was interrupted, or anywhere in between.

21. This is a simple reminder to set the wire Speed control to the desired speed prior to beginning.

22. This screen appears if and only if the bow sensor is reading a value greater than zero. If you had

temporarily stopped a cut in progress and are now about to resume, the wire is likely already

embedded in the specimen and already bowed. In this case, the bow is appropriate and you should

skip the warning message by pressing the right arrow key to proceed. However, if the wire is not

currently engaged and is stretched straight between the guide pulleys, this warning indicates that

the bow sensor is in need of calibration. Switch to Manual mode and calibrate the bow sensor. See

Calibrate Bow Sensor

in the

Adjustment and Maintenance

section for instructions.