26

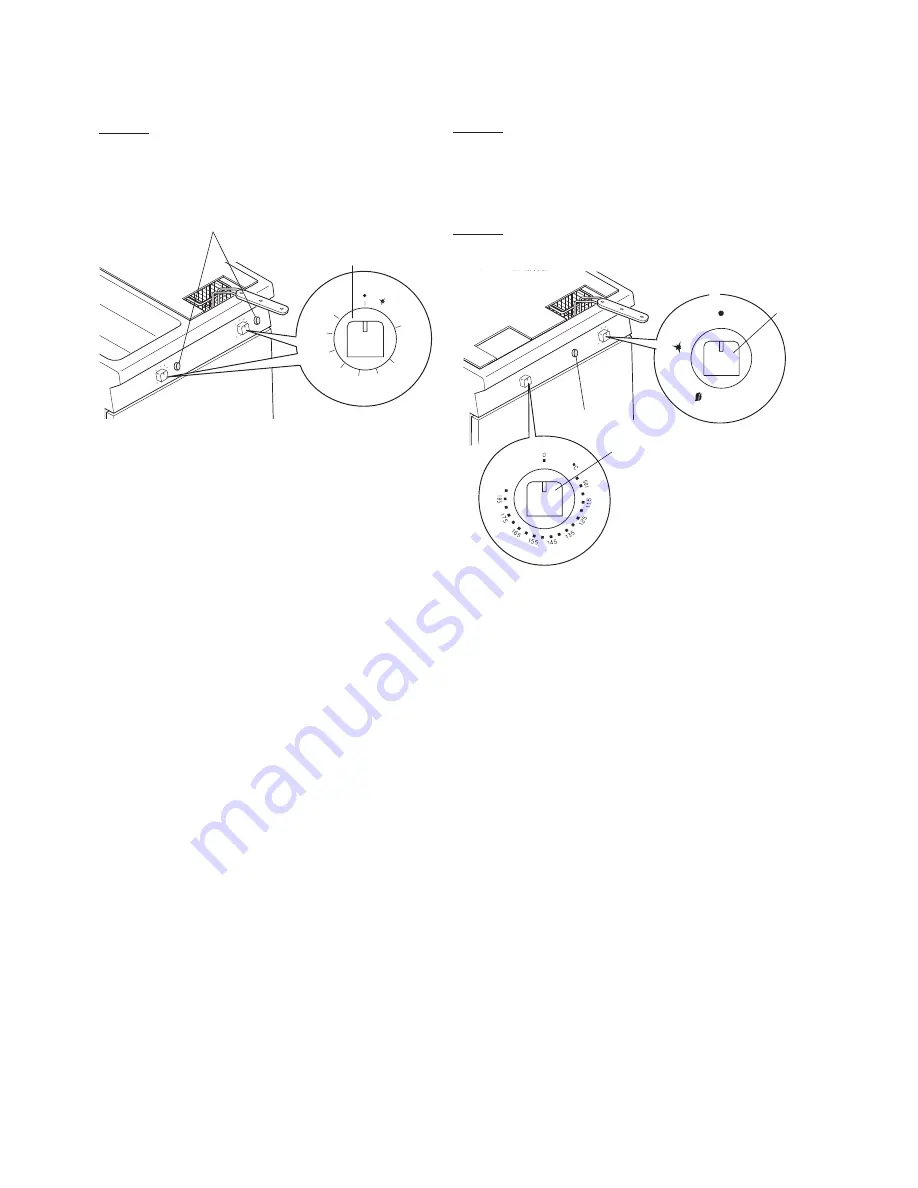

Switch-on (7 L)

Control knob “A” has the following positions:

Knob A:

V

“Off” position

C

“Pilot ignition” position

-

Temperature values

2

7

0

25

0

230

21

0

190

17

0

150

110

2

7

0

250

230

210

1

90

1

7

0

15

0

110

C

11

0

125

140

155

170

180

190

A

B

•

Press and turn knob “A” to “pilot on”, at the same time

press piezoelectric igniter button “B” repeatedly.

•

On releasing knob “A”, the flame must remain alight,

otherwise repeat the operation. In case of emergency,

the pilot can also be lit manually by bringing a flame to it

through hole “C” and keeping knob “A” pressed in the “pilot

ignition” position for the time necessary.

•

Turn knob “A” to the required temperature. The burners light

up and heating starts.

•

When the oil in the tank reaches the set temperature, the

main burners go off and light up again when the

temperature falls below the same value.

•

Place the basket with food to be cooked, slowly in the boiling

oil, making sure that the froth formed does not spill over

the edge of the tank. If this occurs, stop dipping the basket

for a few seconds.

Switching off

•

To switch off the main burners, turn knob “A” to the “pilot

ignition” position.

•

To switch off the pilot flame, press and turn knob “A” to

“off”.

At end of service

•

Turn knob “A” to “off”.

•

Close the gas shut-off cock.

Lighting (40 L Tubes)

Control knob “A” has the following positions:

Knob A:

Control knob “A” has the following positions:

V

OFF

C

pilot ignition

B

max.

Knob B:

Control knob “B” indicates the temperature values

2

7

0

25

0

230

210

19

0

17

0

150

110

B

C

A

• Press and turn knob “A” to “pilot ignition”, hold it down and

press the piezoelectric igniter button “C” several times.

• On releasing knob “A”, after about 20 seconds, the flame

must remain alight, otherwise repeat the operation. In case

of emergency the pilot can also be lit manually by opening

the door and bringing a flame to it, keeping knob “A” pressed

in the “pilot ignition” position for the time necessary.

Important: When turning the knob to “Off” switching

off the pilot burner, wait 60 seconds (knob release)

before relighting it.

• Turn knob “A” to “max.”.

• Turn knob “B” to the required temperature setting.

The burners light up and heating starts.

Note:

First lighting of the pilot when cold involves a delay of

approx. 1 min. in main burner lighting due to inertia of

thermopile heating by the pilot.

• When the oil in the tank reaches the preset temperature,

the main burners go off and light up again when the

temperature falls below the same value.

• Slowly place the basket with food to be cooked in the boiling

oil, making sure that the froth formed does not spill over the

edge of the tank. If this occurs, stop dipping the basket for a

few seconds.

Switching off

• To switch off the main burners, turn knob “B” to the “0”

position.

• To switch off the pilot flame, press and turn knob “A” to

“Off”.

At end of service

• Turn knob “A” to “Off”.