ENGLISH

12

GB

6. CLEANING AND MAINTENANCE

6.1. Recommendations for Cleaning and Maintenance

!

Before carrying out any maintenance

intervention, activate all envisioned safety

devices. In particular, deactivate the electrical

power supply using the automatic disconnecting

switch.

6.2. Routine

Maintenance

Routine maintenance consists of daily cleaning of

all the parts which can come into contact with

foodstuffs and the periodic maintenance of the

burners, nozzles and draining pipes.

Correct maintenance allows the user to maximise

performance levels and operating life and

constantly maintain safety requirements.

Do not spray the appliance with direct jets of

water or high pressure appliances.

When cleaning stainless steel, do not use iron

wool, brushes or scrapers as ferrous particles

could be deposited which, on oxidising, could lead

to rust.

To remove hardened residues, use wooden or

plastic spatulas or abrasive rubber pads.

During long periods of inactivity, spread a

protective layer on all stainless steel surfaces by

wiping them with a cloth soaked in Vaseline oil

and airing the rooms periodically.

!

Do not use products which contain

substances which are harmful and dangerous for

personal health (solvents, petrol etc.).

Periodically

have the following operations carried

out by specialised staff:

Periodically clean the condenser using

suitable tools (suction device or soft

brushes).

Check the perfect sealing of the door

gaskets and replace them if necessary.

Periodically clean the condensate

evaporation tray.

Check that the electric connections have

not loosened.

Check the efficiency of the heating

element (in BT models).

Check functioning of the remote-

thermostat or cards and probes.

check the efficiency of the electrical system.

Routine Maintenance (350+350)

In these models, the two cells have a different

cooling and defrosting system.

In the upper ventilated cell, defrosting takes place

automatically at regular periods by the passage of

hot air. The condensation that is formed is

conveyed into the appropriate tank under the

compressor and then evaporated. No operation is

therefore required by the user.

In the lower static cell, defrosting takes place by

stopping the machine and frequency is at the

user's discretion.

Perform the operations stated below:

1.

Switch the lower compartment off by

acting on the relevant switch

2.

Empty the cell, removing the products

contained

3.

Leave the door open for the time

necessary until the ice formed on the

walls melts; if necessary, ease

detachment from the walls using the

appropriate scraper supplied.

4.

Clean well, dry the cell and reposition the

cap before re-starting the appliance.

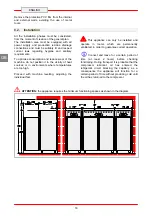

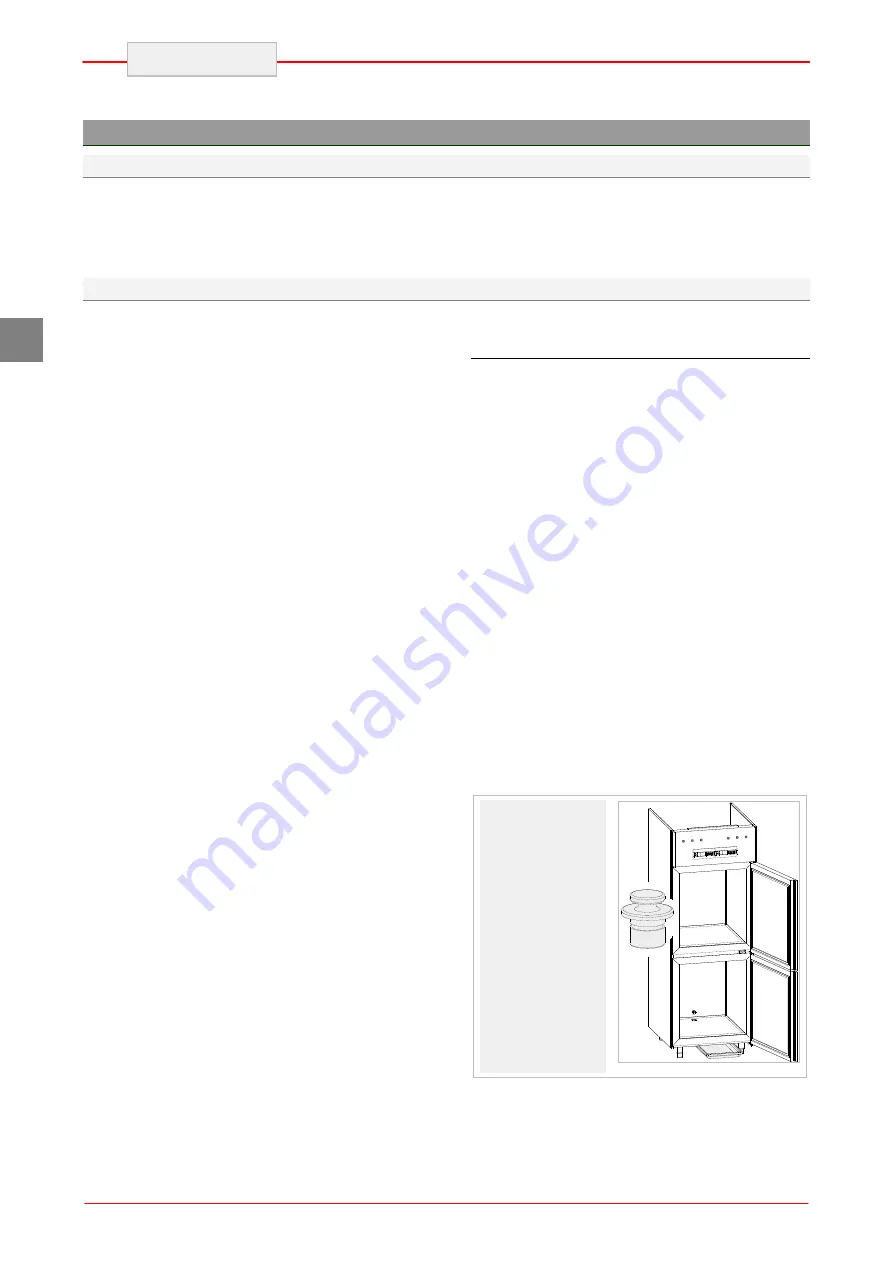

ATTENTION

To ease

evacuation of

the water from

the bottom,

remove the

cap and at the

end of the

operation

empty the

collection tray

positioned

under the

cabinet

as shown in the