DA435HA:

4-1

99901219: 19980930

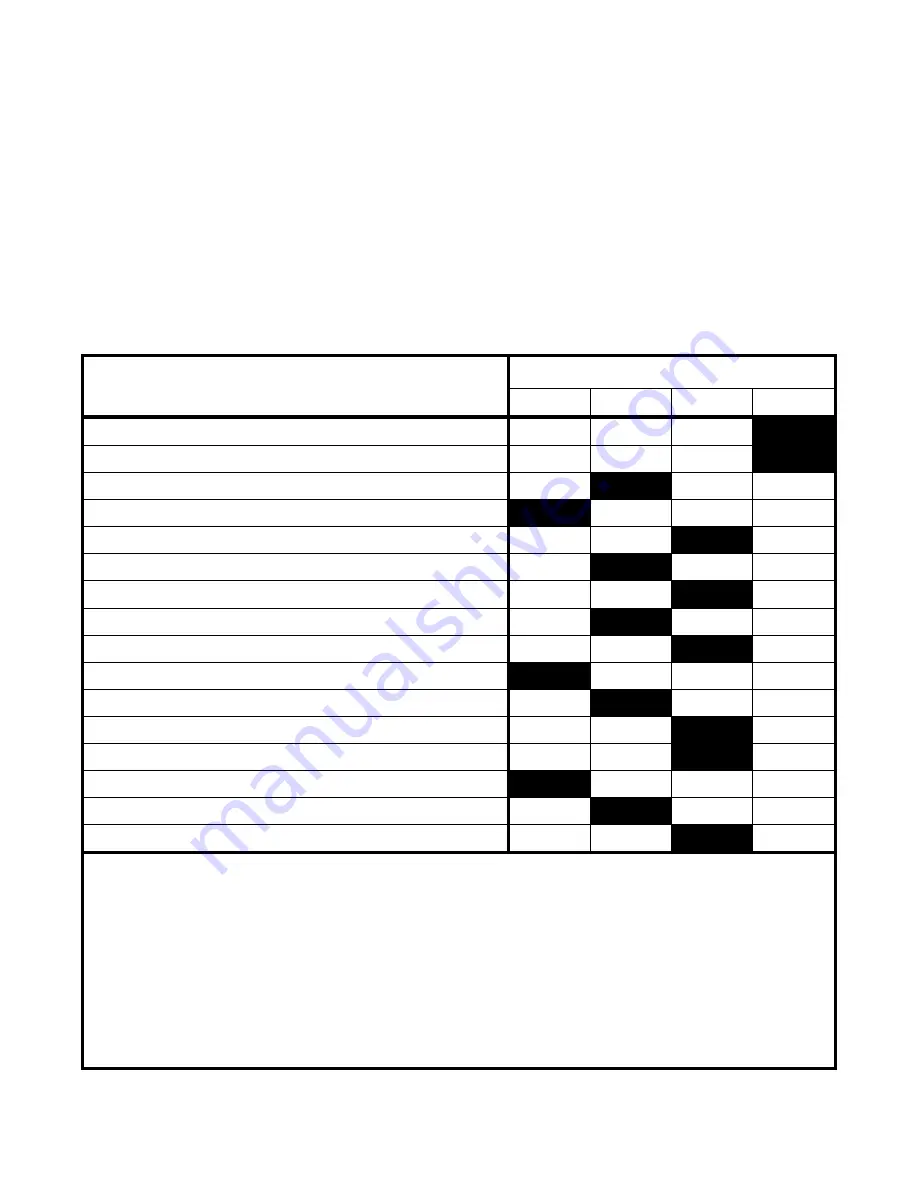

4-1. GENERAL

The following table provides list of routine

maintenance items, including service intervals. The

remainder of Section 4 includes a part lists and

assembly drawings of the compressor.

Section 4. MAINTENANCE & PARTS

FIGURE D-1. ROUTINE MAINTENANCE CHECKLIST

Service intervals are listed as hours/months, whichever occurs first.

Use only IMT’s synthetic compressor oil. The use of any other oil causes excessive carbon buildup, and will void the

warranty on the compressor.

NOTE 1.

Under normal operating conditions, oil changes are required every 3 months. When operating in a dirty environment,

change the oil and air filter more frequently as your particular operating conditions dictate. Oil capacity is 1-1/3 quarts.

NOTE 2.

Cylinder head stud torque MUST be checked after the initial 8-10 hours of operation. The compressor must be cold (room

temperature) before retorquing of studs. Torque studs to 240 in-lbs plus or minus 10 in-lbs.

MAINTENANCE OPERATION

SERVICE INTERVALS

DAILY

WEEKLY

250/3

500/6

AIR INTAKE - INSPECT

CRANKCASE OIL LEVEL - CHECK, ADD IF NEEDED

CRANKCASE OIL - CHANGE (SEE NOTE 1)

CHECK CYLINDER HEAD STUD TORQUE (SEE NOTE 2)

COOLING VANES (FINS) - CLEAN

SAFETY VALVES - CHECK OPERATION

SAFETY VALVES - CLEAN

AIR RECEIVER - DRAIN CONDENSATION

RECEIVER SAFETY VALVES - CHECK OPERATION

TIGHTEN AND CHECK ALL VALVES

CHECK ALL ELECTRICAL CONNECTIONS

CHECK FITTINGS AND AIR LINES FOR LEAKS

INSPECT CHECK VALVES FOR PROPER OPERATION

INSPECT CHECK VALVES FOR CARBON BUILDUP

AIR CLEANER - CHANGE

INSPECT DRIVE COUPLING FOR WEAR