DA435HA: 99901219:

5-1

SECTION 5. REPAIR

19980930

5-1. GENERAL

This section describes the disassembly and assembly

procedures for the air compressor. In all cases,

remove the compressor from the vehicle before

proceeding with disassembly and repair within a

clean environment. Refer to the parts drawing in

section 4 of this manual for parts locations.

5-2. PISTON RING REPLACEMENT

1. Remove the pulsation tank.

2. Unscrew the head bolts and remove the heads.

NOTE

A RUBBER FACED MALLET WILL HELP WHEN

REMOVING THE HEAD. TAP THE SIDES OF THE HEAD

CAREFULLY UNTIL THE HEAD IS LOOSE. LIFT OFF

THE HEADS.

3. Remove the cylinder bolts. Tap the sides of the

cylinder several times to break it loose from the

gasket. Rock the cylinder back and forth and lift

until it is free. Lift it off the pistons.

4. Use a single edged razor blade, or sharp

putty knife, to remove the old gasket material.

CAUTION

DO NOT ALLOW THE GASKET MATERIAL TO FALL INTO

THE CRANKCASE. DO NOT NICK THE HEAD,

CYLINDER, OR CRANKCASE MATING FACES WHILE

REMOVING THE OLD GASKET. REMOVE ALL OF THE

OLD GASKET MATERIAL TO PROVIDE A SMOOTH,

CLEAN SURFACE FOR THE NEW GASKET. FAILURE

TO FOLLOW THIS PROCEDURE MAY RESULT IN THE

NEED TO RESEAL THE UNIT LATER.

5. Hone the cylinder to break the glaze and to

remove the buildup at the top of the cylinders.

6. Measure the inside diameter of the cylinder for

roundness and excessive wear. The bore should be

2.625" (0.0025" tolerance). If the bore is oversized,

the cylinder must be replaced.

7. With a ring expander, remove the compression

and oil rings.

8. With the ring expander, install the new ring kit.

Make certain that the oil ring is on the bottom and

the beveled inside edge of the compression ring is

toward the top of the piston.

9. Position the cylinder base gasket on the

crankcase. Use a few drops of oil to hold it in

position. Install the cylinder block spacer and gasket

on the crankcase.

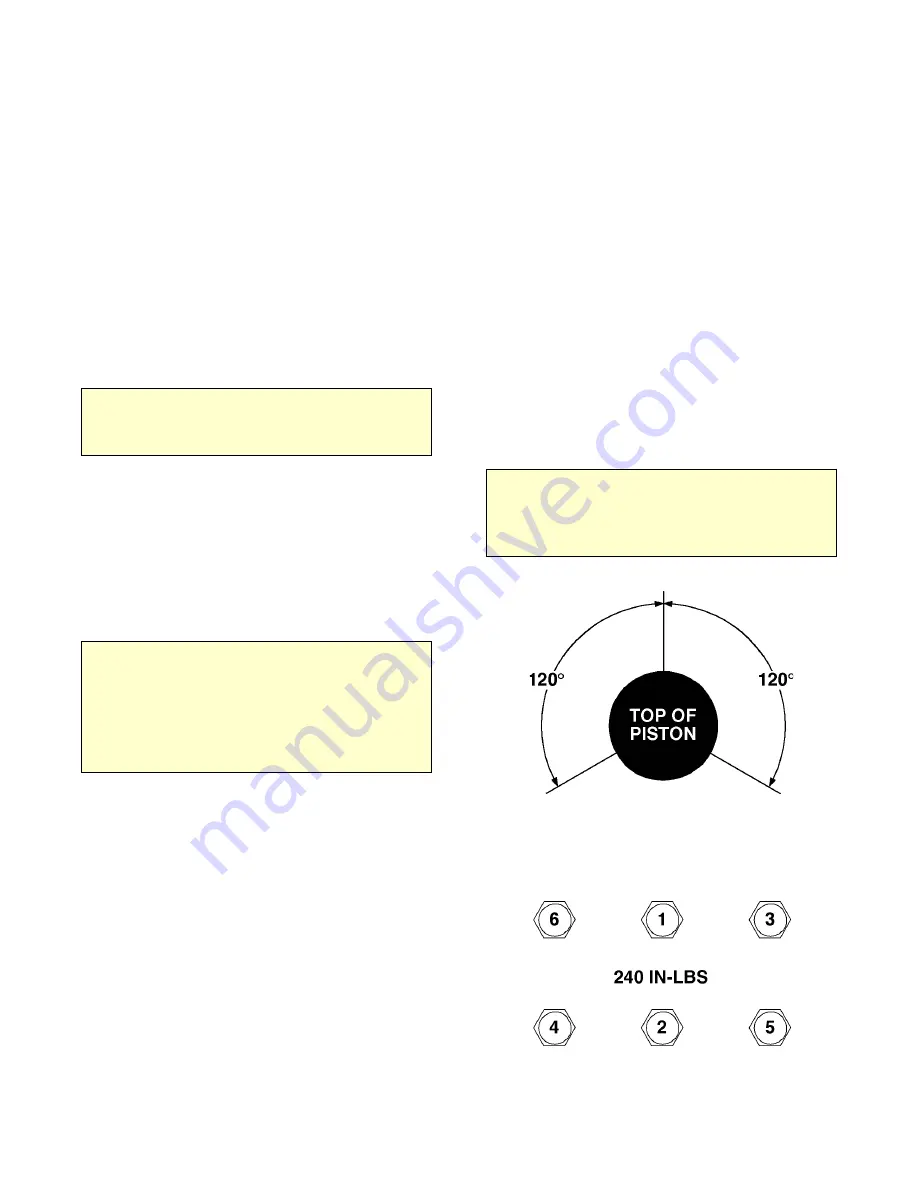

10. Rotate the rings so that the gaps of the three

rings are 120° apart. Lightly lubricate the inside of

the cylinder. Rotate the crankshaft so that a piston is

at the top of the stroke. Compress the rings with a

ring compressor, and slide the cylinder over the

piston. Repeat for the other piston.

CAUTION

DO NOT LUBRICATE THE RINGS. USE A LIGHT

LUBRICANT, SUCH AS WD-40 ONLY, ON THE

CYLINDER WALLS. OILING THE RINGS WILL

PREVENT THEM FROM SEATING AND CAUSE

EXCESSIVE OIL CONSUMPTION.

FIGURE E-2. CYLINDER HEAD TORQUE

SEQUENCE

FIGURE E-1. PISTON RING

ORIENTATION