DA435HA: 99901219:

5-2

19980930

11. Slide the cylinder down until it mates with the

crankcase. Start all cylinder mounting bolts, until

they are snug. Torque the bolts to 180 in-lbs in the

sequence shown. Do not torque to the full 180 in-lbs

all at once, but in 25-50 in-lb increments.

12. Position the gaskets and valve plate on top of the

cylinder. Position the head on the cylinder and turn

studs finger tight. Torque the studs/nuts to 240 in-lbs

in 25-50 pound increments per Figure E-2.

NOTE

INSTALL THE VALVE PLATE WITH THE MARKED

SURFACE FACING UP.

13. Install the pulsation tank, and torque to 180 in-

lbs.

14. Install the compressor, connect the wiring and

the air lines. Test the unit.

NOTE

IF PRESSURE FAILS TO BUILD AND THE

COMPRESSOR IS EXCESSIVELY NOISY, CHECK THE

VALVE PLATE. IT MAY HAVE BEEN INSTALLED UPSIDE

DOWN.

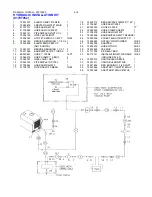

5-3. OIL PUMP REPLACEMENT

1. Remove the bolts and lift off the pump

cover.

2. With a single edged razor blade, or sharp putty

knife, remove the old gasket material. Take care not

to damage the machined surfaces.

3. Lift the pump out of the cavity.

4. Position a new gasket on the rear bearing

housing.

5. Insert the pump into the cavity. Position the

pump slightly to one side, using a common

screwdriver. Wedge the pump into position so that it

partially compresses the spring. Note that the driver

pin and slot in pump must be in line.

6. Place the pump cover into position and start two

bolts (bolts must be diagonally opposed). Strike the

pump cover with a rubber faced mallet to jar the

pump loose. When the tension spring can be felt

against the pump cover, the pump is loose.

7. Insert the two remaining bolts and torque to 180

in-lbs. The bolts should be torqued in a diagonal

pattern.

8. Install the air compressor in the vehicle.

Connect the air lines and wiring.

5-4. CRANKSHAFT AND BEARING

REPLACEMENT

If it is necessary to replace the crankshaft, related

components must also be replaced. Replace both

bearings, both races, the key, pump collar and pump

drive pin.

NOTE

DEPENDING ON THE CONDITION OF THE

CRANKSHAFT, BEARING MAY BE REPLACED

WITHOUT REPLACING THE CRANKSHAFT. REPLACE

THE BEARING RACES WHENEVER THE BEARINGS

ARE REPLACED.

1. Remove the pulsation tank, both heads,

cylinders, and pistons.

2. Remove the bolts on the connecting rods, and

lift them out. Reassemble the connecting rods to be

certain that the matched parts remain together on the

same crankshaft journals.

3. Remove the pump cover, oil pump, sleeve,

spring, and rear bearing housing.

4. Remove the hydraulic motor hub (#301266), and

the front bearing housing.

5. Pull the crankshaft from the crankcase.

6. Remove all gasket material with a single edged

razor blade, or sharp putty knife.

CAUTION

DO NOT GOUGE THE MACHINED SURFACES WHEN

REMOVING THE GASKETS. THIS MAY CAUSE LEAKS.

7. Press the bearing races out of the bearing

housing.

8. Press the tapered roller bearings off of the

crankshaft if only the bearings are being replaced. If

the crankshaft is to be replaced, discard the entire

assembly.

9. Press the new bearings into position.