OPERATOR’S MANUAL

IntelliAg PDC User Level 1

11001-1510-200904

TROUBLESHOOTING & ALARMS / 27

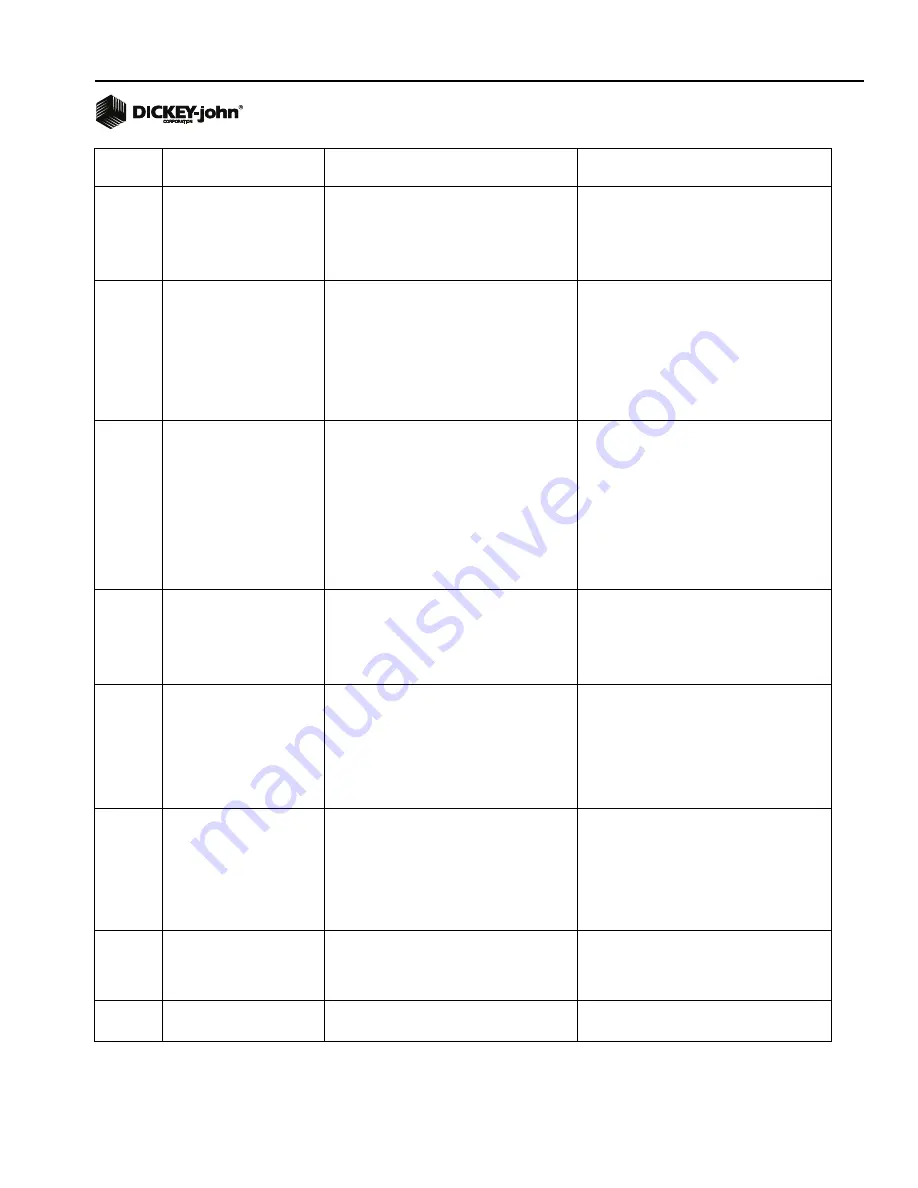

264

Ground Speed Calibration

Calibration Configuration

Alarm

Current ground speed calibration exceeds

the max number of ground speed pulses of

50000 that can be entered as a ground

speed constant.

1. Probable that the marked off course

limits were exceeded. Verify course length

of 400 ft (100 m).

2. Ground speed sensor has too high

resolution of pulses. Check speed sensor

for damage.

602

8 Volt Supply Failure

Alarm

8V SUPPLY VOLTAGE IS BELOW 7.2V

OR HIGHER THAN 16V.

1. Damaged module harness.

2. Defective seed or hopper sensor.

3. Defective module.

1. Inspect module harness for damage.

Repair or replace harness.

2. Inspect seed or hopper sensors

connected to the identified module for

damage. Replace sensors if necessary.

3. Replace identified module.

603

Member Module

Communication Failed

Alarm

COMMUNICATION WITH AN ACTIVE

MODULE HAS FAILED

1. Damaged CAN or module harness.

2. Blown module harness fuse.

3. Defective module.

1. Identify missing module in the Module

Configuration list. Inspect CAN/module

harness of the missing module for damage.

Repair or replace harness.

2. Inspect module harness fuse, replace if

necessary.

3. Identify missing module in the Module

Configuration list. Inspect missing module

for damage or replace.

604

ECU Voltage Out of

Range Alarm

ECU VOLTAGE IS BELOW 11V OR

HIGHER THAN 16V.

1. Damaged CAN or module harness.

2. Defective module

1. Inspect CAN/module harness of the

identified module for damage.

2. Inspect identified module for damage or

replace.

605

Solenoid Voltage Out of

Range Alarm

SOLENOID VOLTAGE IS BELOW 11V OR

HIGHER THAN 16V.

1. Damaged CAN or module harness.

2. Blown module harness fuse.

3. Defective module.

1. Inspect CAN/module harness of the

identified module for damage. Repair or

replace harness.

2. Inspect module harness fuse or replace.

3. Inspect identified module for damage or

replace.

606

Ground Offset Voltage

Out of Range Alarm

1. Damaged/shorted Actuator Harness.

2. Defective PWM valve driver or Servo

valve driver.

3. Defective module.

1. Inspect Actuator Harness for damage

around the WPM and Servo valve

connections. Repair or replace harness.

2. Inspect PWM or Servo valve drivers for

damage and replace if necessary.

3. Inspect identified module for damage

and replace if necessary.

607

Task Controller Task

Stopped Alarm

1. Control rates no longer set by Task

Controller.

1. Press TC RATE to keep the last target

rate from the Task Controller.

2. Press MAT RATE to use the target rate

from the material setup.

608

Task Controller Data

Logging Error

1. Task Controller is setting target rates

without logging the data.

1. Restart Task Controller task.

2. Cycle power to entire system.

ALARM

#

ALARM

PROBABLE CAUSE

CORRECTIVE ACTION

Summary of Contents for IntelliAg

Page 8: ...OPERATOR S MANUAL IntelliAg PDC User Level 1 11001 1510 200904 6 PRE OPERATING PREPARATION...

Page 14: ...OPERATOR S MANUAL IntelliAg PDC User Level 1 11001 1510 200904 12 SYSTEM OPERATION...

Page 22: ...OPERATOR S MANUAL IntelliAg PDC User Level 1 11001 1510 200904 20 TROUBLESHOOTING ALARMS...

Page 30: ...OPERATOR S MANUAL IntelliAg PDC User Level 1 11001 1510 200904 28 TROUBLESHOOTING ALARMS...