OPERATOR’S MANUAL

Seed Manager SE ®

11001-1359A-200810

/I

Safety Notices ..................................................................................................... 1

Introduction ......................................................................................................... 3

System Overview .............................................................................................................. 3

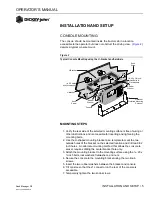

Installation and Setup ......................................................................................... 5

Console Mounting ............................................................................................................. 5

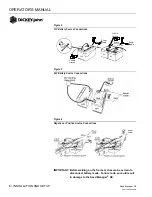

Console Harness Installation ............................................................................................ 6

Power Connection ............................................................................................................. 7

Implement Harness/Module Connection ........................................................................... 9

Module Order ................................................................................................................................... 9

Module Installation ........................................................................................................................... 9

Module Setup Examples ................................................................................................................ 12

Connecting Sensors to Modules .................................................................................................... 14

Hopper Level Sensors .................................................................................................................... 15

Harnesses ....................................................................................................................... 18

12 Row Harness ............................................................................................................................. 18

16 Row Harness ............................................................................................................................. 18

Shaft Speed Module Harness ........................................................................................................ 19

RS485 Extension Harness ............................................................................................................. 19

Startup ............................................................................................................... 21

Switchpad Overview ....................................................................................................... 21

On/Off ............................................................................................................................................. 21

Alarm .............................................................................................................................................. 21

Setup .............................................................................................................................................. 21

Min Avg Max Scan ......................................................................................................................... 21

Select Row ...................................................................................................................................... 21

Select .............................................................................................................................................. 22

Set................................................................................................................................................... 22

Start Stop Reset ............................................................................................................................. 22

Back ................................................................................................................................................ 22

Operate 1 ....................................................................................................................................... 22

Operate 2 ....................................................................................................................................... 23

Operate 3 ....................................................................................................................................... 23

Setup Mode ..................................................................................................................... 24

Setup Constants ............................................................................................................................. 24

Seed Flow Alarm Adjustment ......................................................................................................... 26

Population Hi Limit ......................................................................................................................... 27

Population Lo Limit ......................................................................................................................... 27

Row Width ...................................................................................................................................... 27

Implement Width ............................................................................................................................ 28

Ground Speed Source ................................................................................................................... 28

Distance Calibration ....................................................................................................................... 28

Automatic Configuration ................................................................................................................. 29

Split Row Configuration .................................................................................................................. 30

Number of Seed Modules .............................................................................................................. 31

Row Status ..................................................................................................................................... 32

Total Number Of Rows Configured ................................................................................................ 33

Number of Fan Speed Sensors ...................................................................................................... 33

Number of Shaft Speed Sensors ................................................................................................... 35

Summary of Contents for seed manager

Page 4: ...OPERATOR S MANUAL Seed Manager SE 11001 1359A 200810 2 SAFETY NOTICES...

Page 6: ...OPERATOR S MANUAL Seed Manager SE 11001 1359A 200810 4 INTRODUCTION...

Page 22: ...OPERATOR S MANUAL Seed Manager SE 11001 1359A 200810 20 INSTALLATION AND SETUP...

Page 46: ...OPERATOR S MANUAL Seed Manager SE 11001 1359A 200810 44 STARTUP...

Page 64: ...OPERATOR S MANUAL Seed Manager SE 11001 1359A 200810 62 SELF TEST ERROR CODES...

Page 70: ...OPERATOR S MANUAL Seed Manager SE 11001 1359A 200810 68 SELF TEST ERROR CODES...