System Inaccurate

(continued)

Mounts, Platform or Cart Not Shimmed or Supported Properly to

Provide Equal Load at Each Load Cell:

On MOBILE applications, side pressure on a wheel or tongue can cause inaccurate

readings. Make sure wheels are on a level surface and there is no draw bar pull on

tongue.

On PLATFORM applications, use a large screwdriver or pry bar to pry up on the corners

of the deck. If one of the corners has noticeably less resistance, the deck may require

shimming or adjustment of the leveling screws (if present).

On FEED BIN applications, rock the bin back and forth, and check the mounts for any

movement or play. Insure that each mount has equal pressure and is secured to the slab.

Defective Load Cell:

If you suspect that you have a defective load cell, test them using the procedure on page

11.

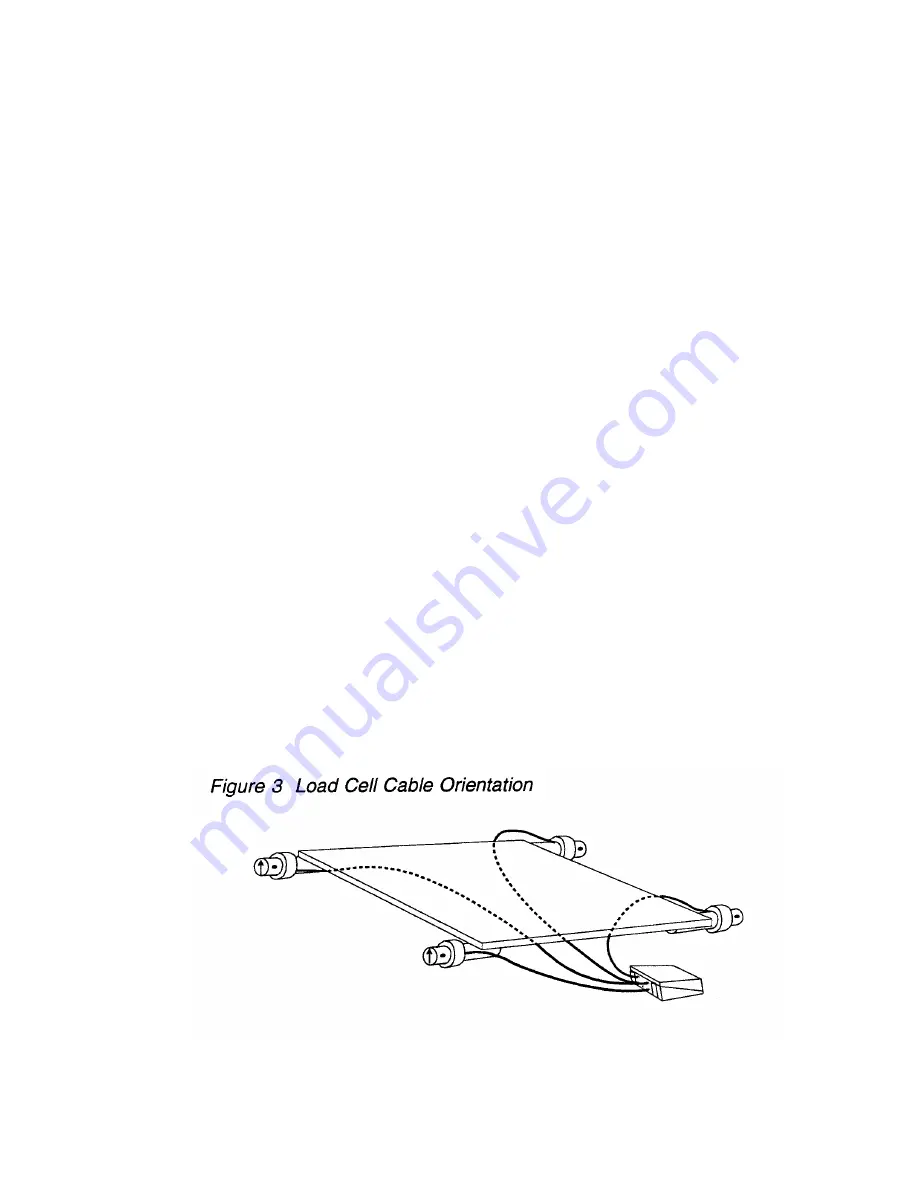

Load Cell Up-Side Down:

If one load cell is mounted up-side down, the corner with the upside-down cell would read

negative. Visually check load cells for proper orientation (see below). The load cell should

deflect the same direction as the black arrow on the end of the cell.

NOTE: Each load cell is manufactured so that the cable comes off of the same side of the

cell (see diagram). Decals are also placed on the same side of each load cell.