Digicare Biomedical Technology

Operators Manual Multi-parameter Patient Monitor " LifeWindow Lite LW8 "

42

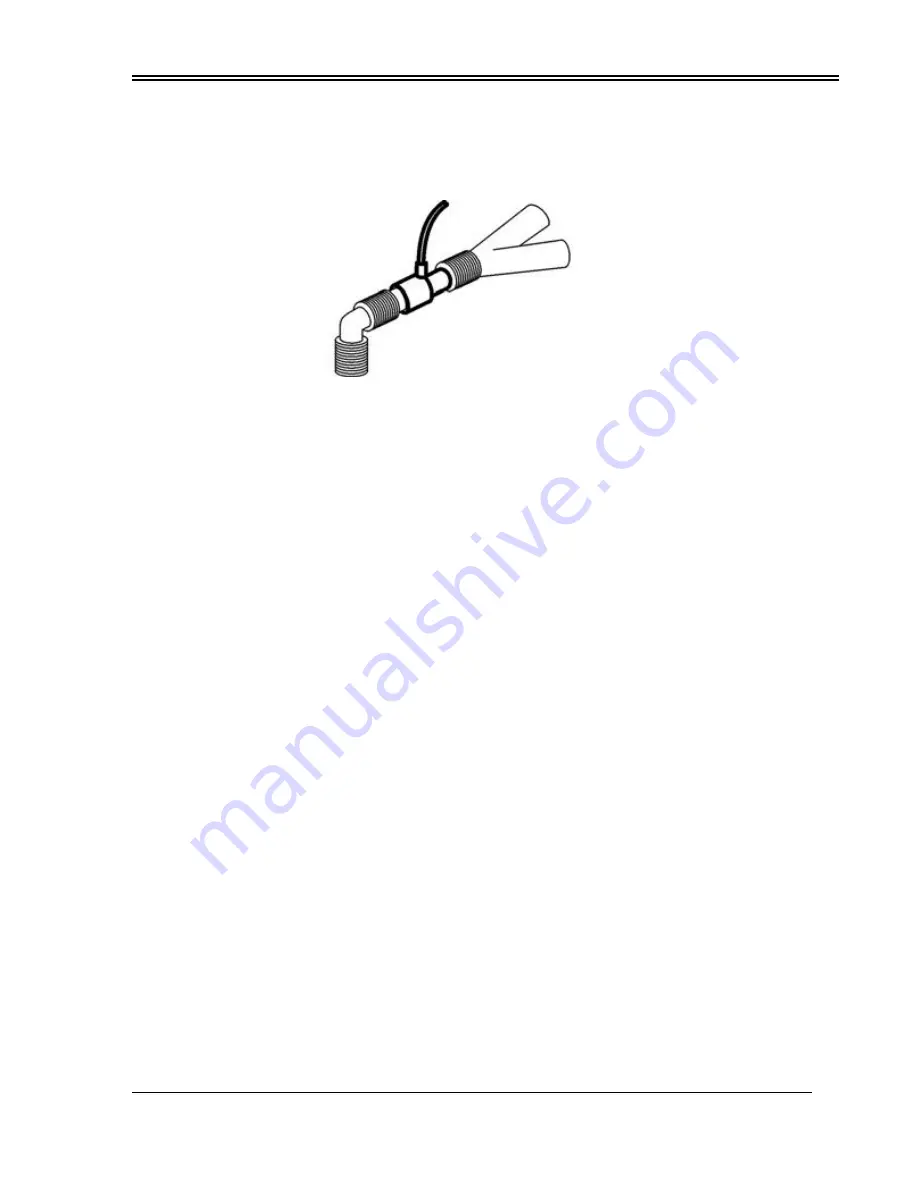

• Place the on-airway adapter at the proximal end of the airway circuit between the elbow

and the ventilator circuit wye.

• Check that connections have been made correctly by verifying the presence of a proper

capnogram on the Patient Monitor.

Figure 3

• CAUTION: Always insert the Sample Cell of the Sample line into the Sample Cell

Receptacle on the MicroFlow™ CO2 sidestream module before inserting the on-airway

adapter into the ventilator circuit. Failure to follow this, may introduce a leak in the circuit,

thereby reducing set minute volume.

• CAUTION: Remove the MicroFlow™ sample cell from the receptacle when not in use.

• NOTE: Do not place the on-airway adapter between the ET tube and the elbow as this may

allow patient secretions to accumulate in the adapter. If pooling does occur, the on-airway

adapter may be removed from the circuit, rinsed with water (or sterile water) and reinserted

into the circuit. If rinsed, make sure that no water has entered the sampling tubing. If so, blow

out water or replace the sample line. To prevent moisture from draining into the on-airway

adapter kit tubing, always place the on-airway adapter tubing in an up position (see Figure 3).

6 – CHECK SAMPLE LINE MESSAGE

• The sample flow rate of the MicroFlow™ CO2 sidestream module is continually monitored. If

the flow rate falls outside the nominal operating range and continues for 15 seconds, the

message “Check Sample Line” will be displayed. The pump will shut off after 2 minutes if the

condition that caused this change is not corrected.

7 – CONDITIONS THAT CAN CAUSE A CHANGE IN FLOW RATE

• Water, mucous or other patient contaminate has entered the sample tubing.

• The sample tubing is crimped or pinched so that the sample flow rate has decreased.

• The exhaust port of the MicroFlow™ CO2 sidestream module is obstructed.

• The sample line is damaged.

• The sample line has been cut, or split, causing the flow rate to increase.

8 –CLEARING THE “CHECK SAMPLE LINE” MESSAGE

• When the “Check Sample Line” message is displayed, the user should inspect the sample

line kit to verify that none of the conditions described above are present. Replace with a

new sample kit if needed.

• If the user removes the sample cell for inspection and then reinserts the sample cell without

correcting the condition, the “Check Sample Line” message will reappear.

• The user should verify that the exhaust port is not obstructed or blocked. If tubing is

connected to the exhaust port, the user should also inspect the tubing for any crimping or

pinching.

Summary of Contents for LifeWindow Lite LW8

Page 1: ......