Cleaning the Unit

3-11

82275345-003

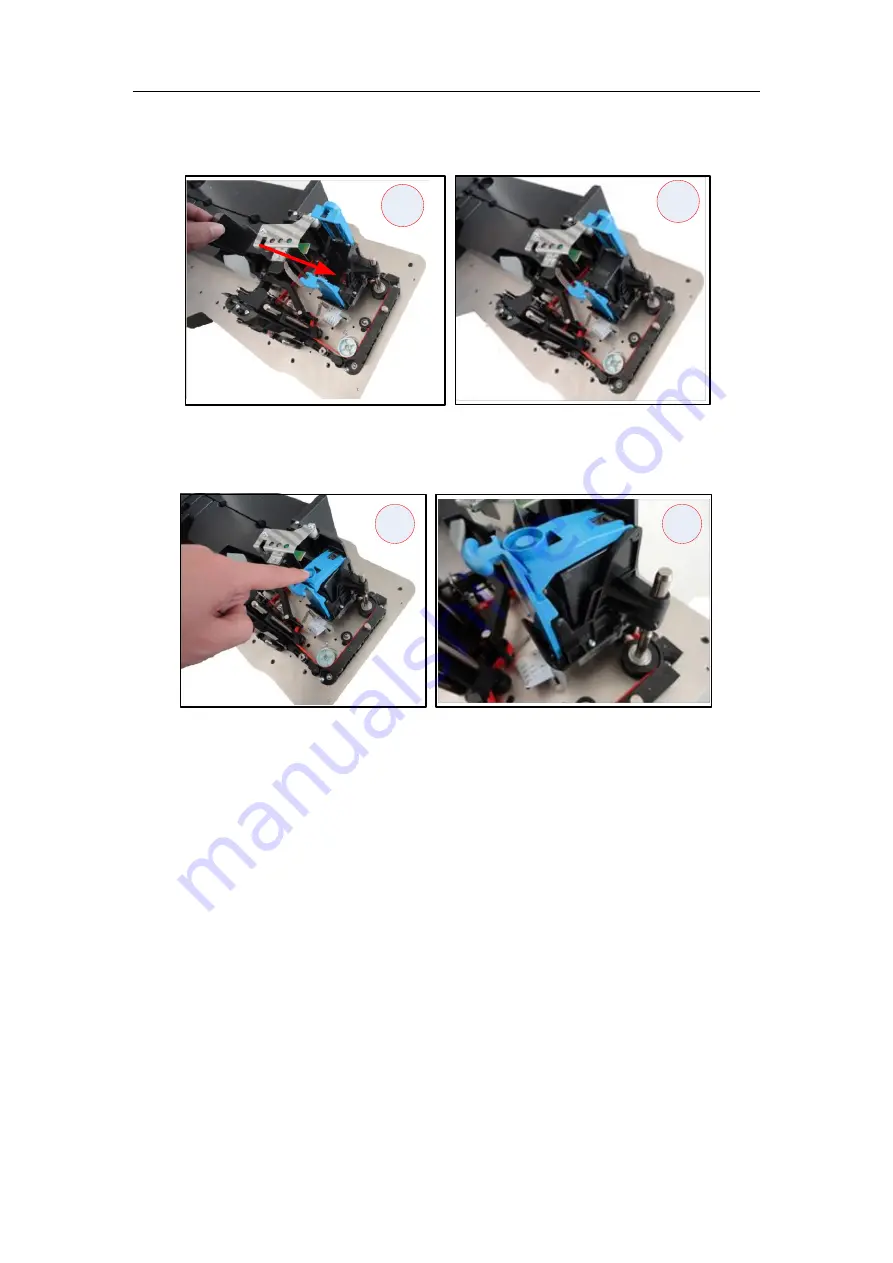

On the unit, place the cartridge back inside the housing assembly and push it

down into place.

1

2

Press the top of the cartridge housing assembly down until it is latched and

closed.

4

3

11.

If print quality does not improve, repeat steps 1 through 10 of this

procedure one more time.

12.

If print quality still does not improve after two cleanings, the cartridge may

be empty or defective. Replace the cartridge.