Installation & Operations Guide - SmartSource Expert Micro Elite

June 2019

8227 6059-001

Page 28 of 30

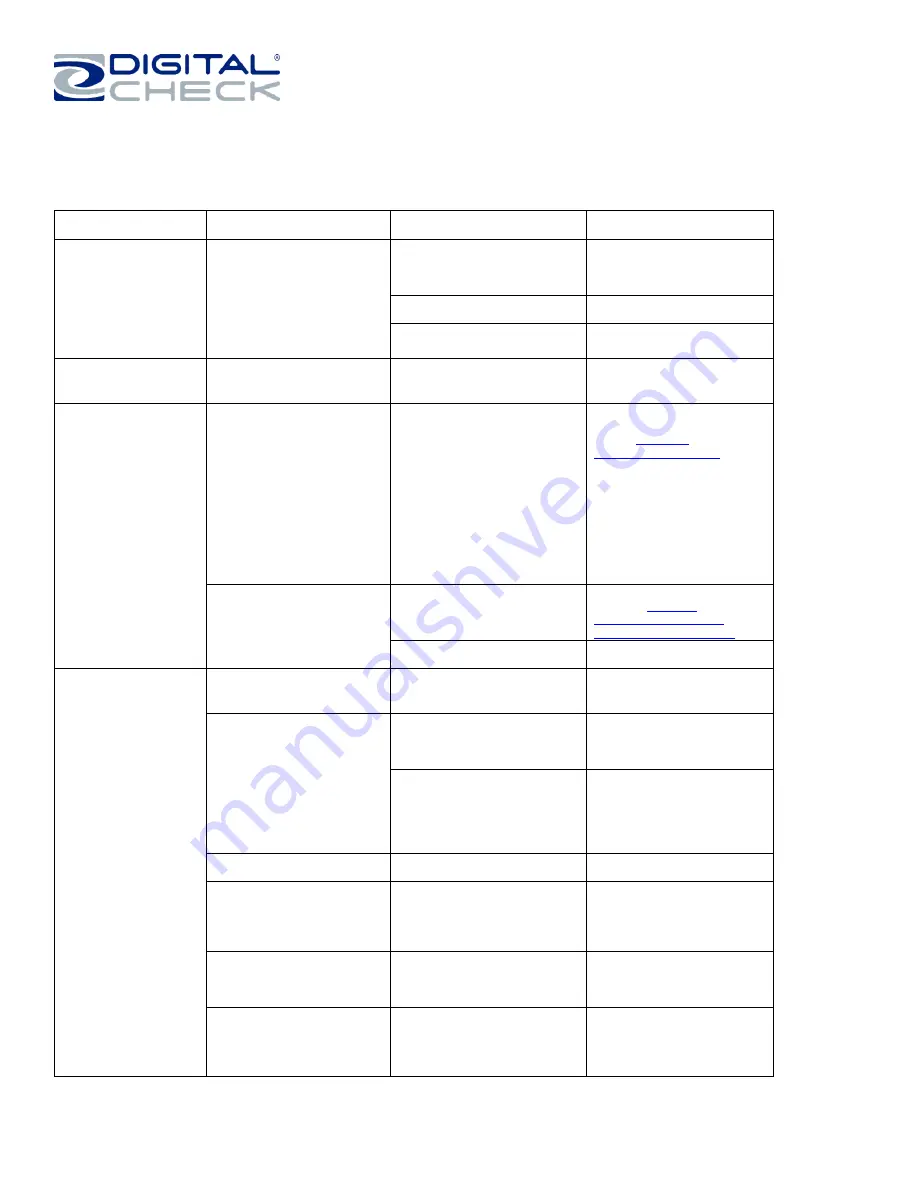

Detailed troubleshooting chart

For more-detailed descriptions of how to resolve operating errors, please refer to the following troubleshooting chart.

Problem

Topic

Condition/Problem

Possible Cause

Corrective Action

Power Supply

Scanner will not

power up. Blue LED

in function switch is

not lit, scanner is off.

Not plugged into AC

outlet,

Plug into a known-good

AC outlet

Non-functioning AC

outlet

Verify AC outlet is OK, try

a different AC outlet

Defective power supply

Replace power supply

Track Noise

Clicking or ticking

noises as document

travels in track

Obstruction in

document track

Inspect track, remove

debris.

Indicators /

Controls

See page 13

for power

button light

interpretation

chart on all

Expert Micro

Elite models

starting with

serial #

9203xxxxx

Power light does not

come on

Multiple causes

See ‘Power Supply’

conditions, above. Also,

refer to

Items do not feed

when button is

pressed

Button is not being

operated correctly

Refer to ‘Power Button

Function’

power/start-stop button /

meaning of the status light

Application is not ready

Consult application

documentation

Frequent

Jams or

Stops

Track stops

frequently with the

same error message

Error message will

indicate the cause of

the repeated problem

Use error message to

identify the appropriate

problem area

Track stops/fails to

start with a

‘document in track’

message

Document or debris is

stopped in track and

blocking track sensor

Inspect and clear as

required.

Several different jams

are “mapped” into this

single message, a

“decoding” effort will

reveal what area of the

track reported the jam

Consult with your IT or

application provider to

analyze error codes.

Items do not feed

correctly

Multiple causes

See “Feeder” conditions

below

Items feed into the

track but then stop

suddenly and have

leading edge

damage

Debris/obstruction in

paper path

Examine paper path to

locate small bits of paper,

tape, staples, etc.

Remove debris gently

using the spatula tool.

Item stops in curved

portion of track

Item is too thick or too

stiff-run through ID

card track.

Card stock, envelopes,

carriers will not travel

correctly if they are too

thick or too stiff.

Items skew as they

are fed

Inadequate document

preparation

Ensure document is

properly aligned on base-

floor bottom