Installation & Operations Guide - SmartSource Micro Elite IJ

Rev. 022720

8227 5727-003

Page 20 of 27

The more-frequently and more-thoroughly the track is cleaned, the fewer processing problems you will experience due to

dust and dirt. Excessive accumulation of dust and dirt will cause processing problems such as jams, document damage

and poor image quality, and may degrade the life of the unit. It is easier to avoid these problems by cleaning the track

regularly so that dust, dirt and foreign objects do not accumulate.

For heavier accumulations of dust and dirt, which a cleaning card will not remove, use canned compressed air, or piped

compressed air where available. Air should be regulated to no more than 30 psi (2.0 bar, 200 kPa). Open the front cover

and image cover, and blow the track and surrounding walls and rollers clear of dust and debris. (Canned compressed air

and additional cleaning cards are available from the Digital Check Store,

part numbers 75-0501-

900 and 75-7200-995 respectively)

If foreign objects cannot be blown out with compressed air, you can attempt to remove them using a non-metallic tool or

probe such as the Digital Check track-cleaning tool (available from the Digital Check Store,

, part

number 75-0381-907).

Do not use any metallic tool or probe, as damage to the track walls and other parts may result.

Do not use any magnetic tool, as damage to the MICR read head may result.

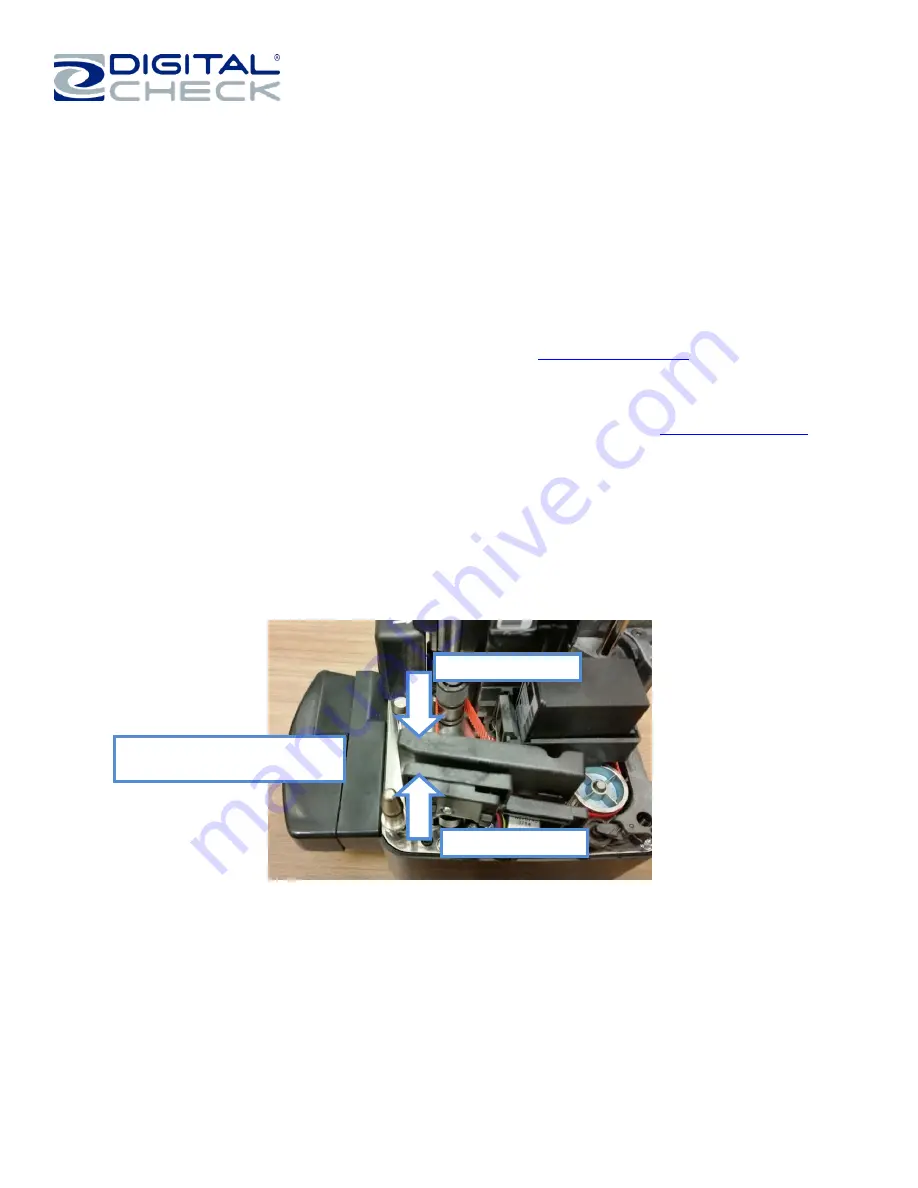

The track contains two powerful magnets which are located about

¾”

in from the document entry as shown.

Foreign objects such as staples and paper clips will often stick to these magnets, making them easier to find and remove.

Magnets are located in both sides

of the track towards the base

plate…

…here…

… and here.