Service Manual

7-3

Cleaning and Maintenance

7

The two clutches used in the printer look slightly different but function and

are serviced in the same manner. Refer to the Section 8 topics “Paper-pick

roller, clutch, and paper-empty flag” on page 8-9 and “Lower aligning roller,

clutch, and paper-pass sensorþ1þflag” on page 8-11 for the procedures on

removing the clutches.

n

White plastic gear train: This gear train from the paper-feed motor to the

paper-feed module requires only a small amount of white grease for noise

reduction purposes. Apply it sparingly so that the grease does not fling off of

the gears when they turn. You need only to apply a dab of grease to a single

gear and the grease will migrate throughout the entire gear train.

n

White (nylon) plastic bearings and cams: No lubrication required.

Inspecting

Rollers: Replace the rollers when you see any of the following defects:

n

Flat spots.

n

Out of roundness.

n

Cracked rubber.

n

Loss of traction (tackiness) causing consistent pick or feed failures.

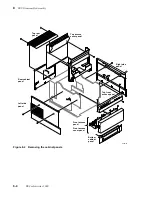

Figure 7-1. Lubricating the clutches

8699-22

Spring end

fits into slot

of clutch sheeve

Spring end

fits into center

hole of clutch boss

E-ring

Washer

Clutch

boss

Clutch

spring

Clutch

sleeve

Gear

Roller

shaft

Summary of Contents for DECcolorwriter 1000

Page 11: ...Service Manual xi...

Page 16: ...Service Manual xv...

Page 56: ...2 24 DECcolorwriter 1000 2 Installing the Printer and Drivers...

Page 64: ...3 8 DECcolorwriter 1000 3 Verifying the Printer and Host Connections...

Page 70: ...4 6 DECcolorwriter 1000 4 Key Operator Training...

Page 170: ...8 46 DECcolorwriter 1000 8 FRU Disassembly Assembly...

Page 190: ...9 20 DECcolorwriter 1000 9 Checks and Adjustments...

Page 195: ...Service Manual A 5 Field Replaceable Units List A...

Page 198: ...A 8 DECcolorwriter 1000 A Field Replaceable Units List...

Page 204: ...C 6 DECcolorwriter 1000 C Wiring Diagrams...

Page 208: ...D 4 DECcolorwriter 1000 D Test Pattern Generator...