5-4

DECcolorwriter 1000

5

Theory of Operation

Plain-paper printing

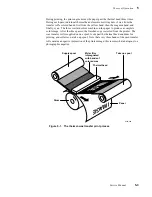

Using the special 4-pass, Plain Paper Transfer Roll, the printer can print on ordinary

Bond paper. In this process, a special coating is applied to the paper in its first pass past

the thermal head. The coating supplies a smooth, flat surface for the yellow, magenta

and cyan wax applied in the following three passes. The coating is applied only to the

portions of the paper where colored wax is to be applied.

Because of the extra pass required for printing on plain paper and the fact that the drum

moves in a slower, half-step mode while laying down the precoat layer, plain-paper print

times are about 10 seconds longer than printing on coated paper with the standard

3-Color transfer roll.

In addition, a greater demand is made on the image processor board's memory for

plain-paper printing. The image processor board must generate a composite bitmap of

the cyan, magenta, and yellow bitmaps. The composite bitmap guides the print engine

on where to apply the precoat on the plain paper.

Summary of Contents for DECcolorwriter 1000

Page 11: ...Service Manual xi...

Page 16: ...Service Manual xv...

Page 56: ...2 24 DECcolorwriter 1000 2 Installing the Printer and Drivers...

Page 64: ...3 8 DECcolorwriter 1000 3 Verifying the Printer and Host Connections...

Page 70: ...4 6 DECcolorwriter 1000 4 Key Operator Training...

Page 170: ...8 46 DECcolorwriter 1000 8 FRU Disassembly Assembly...

Page 190: ...9 20 DECcolorwriter 1000 9 Checks and Adjustments...

Page 195: ...Service Manual A 5 Field Replaceable Units List A...

Page 198: ...A 8 DECcolorwriter 1000 A Field Replaceable Units List...

Page 204: ...C 6 DECcolorwriter 1000 C Wiring Diagrams...

Page 208: ...D 4 DECcolorwriter 1000 D Test Pattern Generator...