5-8

DECcolorwriter 1000

5

Theory of Operation

Thermal head controller

The thermal head controller uses the information received from the heat controller, in

conjunction with timing signals, to drive the thermal head with the data stored in the line

memory buffer. The head controller generates four different strobes. These four strobes

are combined to provide seven drive pulses ranging from 435 uS for “cold” thermal

elements, to 200 uS for “hot” elements. The drive pulses are combinations of these pulse

widths: 145 uS, 120 uS, 90 uS and 80 uS pulses. During printing, the strobe length is

varied, based on the overall thermal head temperature and the volume of dots printed in a

line. The voltage level of the pulse is fixed at 25.5 VDC.

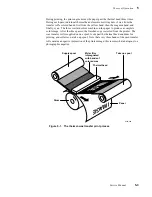

Thermal head

The thermal head is the device that melts wax dots onto paper. It contains a row of 2496

solid-state heating elements. (Only a maximum of 2440 are actually used.) The actual

number of elements used during a particular print depends on the paper size (A or A4)

and the image to be printed. The thermal head prints raster lines parallel to the short axis

of the paper.

Earlier, in the topic “The print process,” we said that the print engine prints one line at a

time; this is not exactly the case, it just appears that way. To simplify its electrical

design, the print engine actually uses a drive signal multiplexing scheme to energize the

heating elements. During printing, the head controller activates a pair of heating element

segments from eight heating segments of the thermal head. (Individual elements in the

segments may or may not be energized depending upon whether the element is to print a

dot; it is just that segments are printed as pairs.) Following the printing of the first pairs

of segments, the head controller energizes the second pair of segments from the eight

heating element segments, then the third pair. Energizing the fourth pair of segments

completes the raster line printing. A line is printed in 1.8 msec.

Mechanical controller

The printer engine mechanical controller interfaces the CPU to the print engine’s motors,

sensors, solenoids and fans. By interpreting signals from the sensors, buffered by the

mechanical controller, the CPU keeps track of the paper drum position, transfer roll

position and paper position during printing. Based on this information the CPU

determines the proper time to transmit signals to the mechanical controller to advance

the paper, energize a solenoid, or check a sensor.

Internal test pattern generator

This circuit produces the print engine's internal test patterns. The test pattern algorithms

are stored in ROM. The internal test pattern data are routed to the interface block and

pass through the rest of the print engine just as regular image data would.

Summary of Contents for DECcolorwriter 1000

Page 11: ...Service Manual xi...

Page 16: ...Service Manual xv...

Page 56: ...2 24 DECcolorwriter 1000 2 Installing the Printer and Drivers...

Page 64: ...3 8 DECcolorwriter 1000 3 Verifying the Printer and Host Connections...

Page 70: ...4 6 DECcolorwriter 1000 4 Key Operator Training...

Page 170: ...8 46 DECcolorwriter 1000 8 FRU Disassembly Assembly...

Page 190: ...9 20 DECcolorwriter 1000 9 Checks and Adjustments...

Page 195: ...Service Manual A 5 Field Replaceable Units List A...

Page 198: ...A 8 DECcolorwriter 1000 A Field Replaceable Units List...

Page 204: ...C 6 DECcolorwriter 1000 C Wiring Diagrams...

Page 208: ...D 4 DECcolorwriter 1000 D Test Pattern Generator...