8.1 Image Defects FIP

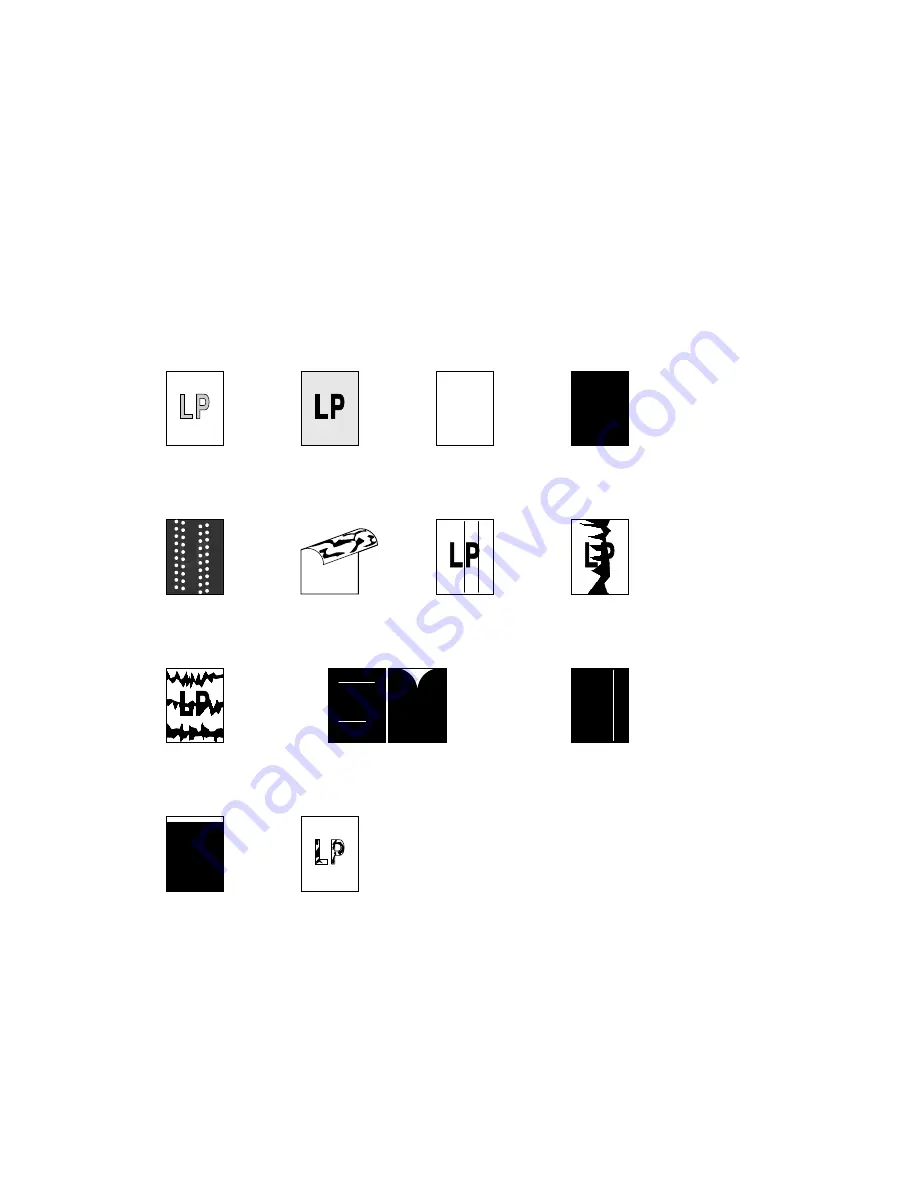

Figure 8–1 Image Defect Examples

Light

Dark

Completely

All black

Large dots

Dirt on back

Vertical black

Irregular and

Irregular and

Blank spots

Solid vertical

Faulty registration

Poor fixing

blank

vertically in a line

of paper

streaks

smudged vertical

bands

smudged horizontal

bands

white lines

MLO-006194

Image Defects FIPS

8–3