4-1

CHAPTER 4 MAINTENANCE

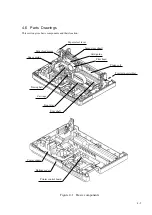

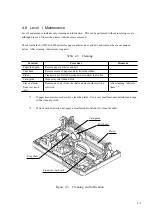

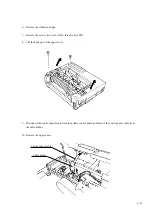

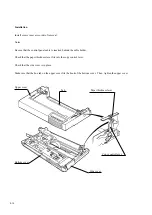

This chapter explains the maintenance levels 1, 2, and 3 for cleaning, lubrication, inspection, and adjustment of

the LA30N and LA30W printers.

4.1

Overview

Designed using the latest technology, the LA30N/LA30W printer offers high reliability and easy maintenance.

Parts requiring lubrication and adjustment have been reduced and the replacement of defective parts made easier

than in previous models.

Difference between LA30N and LA30W is as follows:

• LA30N is an 80-column printer and LA30W a 136-column printer. Therefore, many mechanism components

differ only in size (length).

• Bail rollers of LA30N are mounted on the printer mechanism as the bail roller unit. Bail rollers of LA30W

are built in the top cover.

• Other components are the same.

The printer has useful maintenance functions that can be initiated by the control panel without the host computer.

This greatly reduces maintenance time for testing and adjusting the printer.

The printer also has the self-test print and hex dump functions to indicate whether an error is due to the printer or

the host and to test operation after error recovery.

4.2

Notes on Use

Note the following:

• Do not connect or disconnect connectors or printed circuit boards while power is on.

• Use screwdrivers, wrenches, and other tools suited to the parts being replaced. Do not leave screws or parts

inside the printer.

• Use only the specified type of oil, grease, and cleaning solutions.

• Be sure power is turned off before starting to replace parts.

Summary of Contents for LA30 N

Page 1: ...Order Number ER LA30N SV 003 Service Manual TM LA30N LA30W Companion Printer...

Page 2: ......

Page 5: ......

Page 39: ...3 16...

Page 91: ......

Page 137: ......

Page 140: ......

Page 141: ...TM Printed in Ireland...