Summary of Contents for LA50

Page 1: ...EK OLASO UG 001 Installing and Using the LASO Printer mamaama...

Page 2: ......

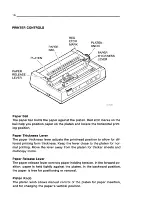

Page 7: ...INSTALLING PRINTER Packing Removal 1 Remove access cover 2 Remove c d ar board ret amer...

Page 9: ...3 3 Replace access cover...

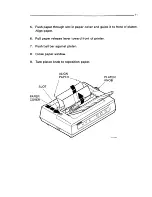

Page 12: ...6 Open paper clamps...

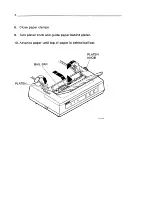

Page 15: ...9 11 Push bail ba r against platen 12 Close paper window 13 Replace paper cover...

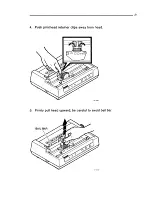

Page 26: ...20 Replacing Printhead 1 Turn off power 2 Remove access cover 3 Remove bb n on cartridge...

Page 27: ...21 4 Push pr mthead ret amer clips away from head MA 10 021 5...

Page 29: ...23 8 Replace b n bon cart d n ge 9 Replace access cover...

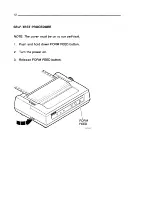

Page 30: ...Replacing Fuse 1 Turn off power MA 10 005 2 Unplug power cord from power outlet...

Page 41: ...Printed in Japan E1 1668 830210000...

Page 42: ...Digital Equipment Corporation Maynard MA 01754...