22

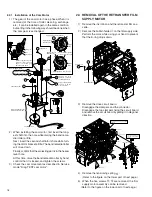

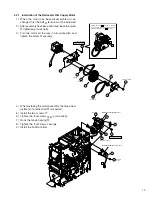

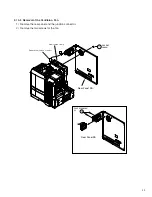

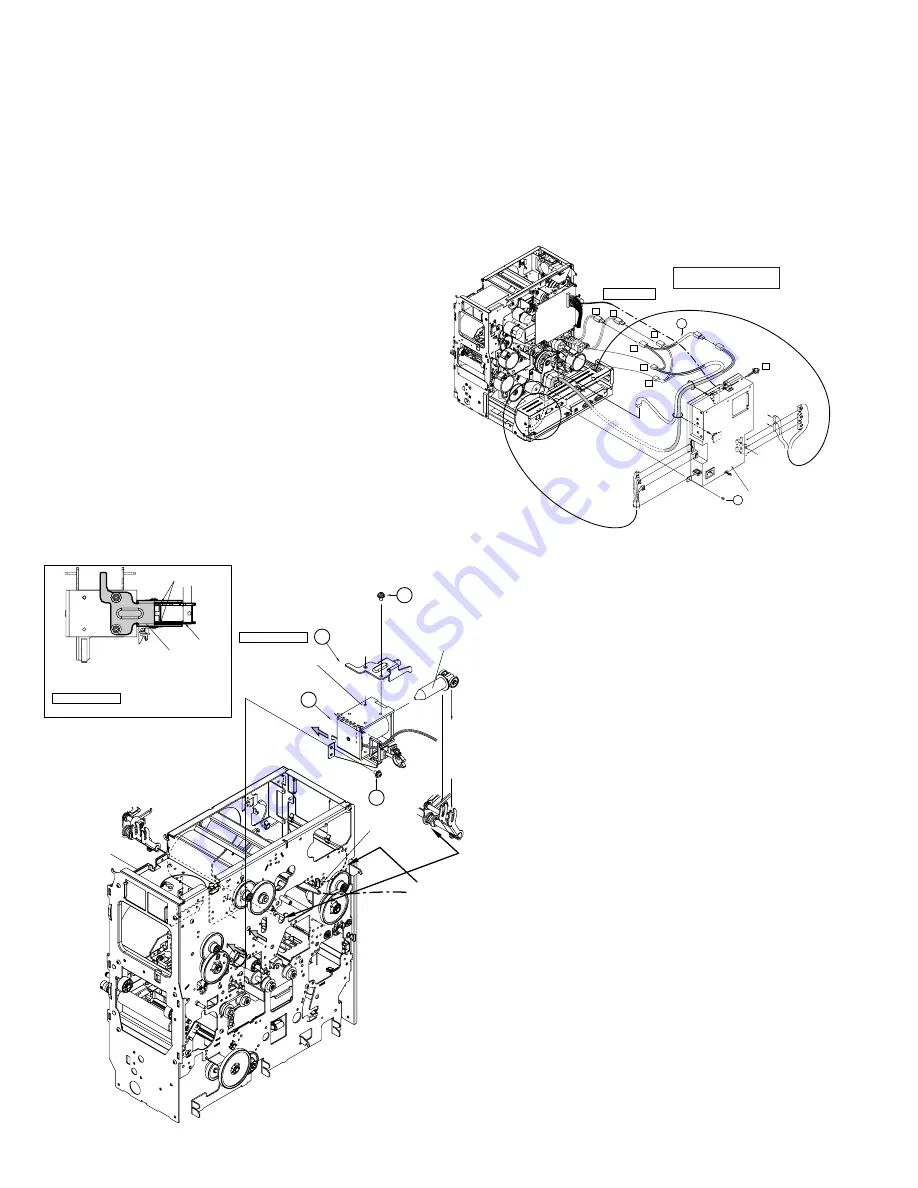

2.10 REMOVAL OF THE PLATEN SOLENOID

1) Remove the drive circuit board.

2) Disengage the wire from the clamp. (2 places)

3) Remove the two screws

(

and then remove the so-

lenoid support

@

and

#

.

4) Remove the two screws

&

, raise the solenoid body

once, and pull it to the rear.

5) Be careful not to damage the disk of ink encoder

located above when removing the screw

(

.

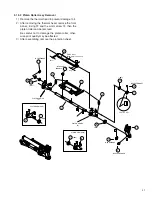

2.10.1 Installation of the Platen Solenoid

1) Insert the plunger by itself into the cutout.

2) Fix the solenoid body with two screws

&

.

3) Fix the solenoid support with two screws

(

. At this

time, Pay attention to the following item.

4) Before tightening the screws, adjust the gap uni-

formly so that there will be no interference with the

platen lever and the solenoid support when the

plunger moves in and out.

5) Be careful not to damage the disk of ink encoder

located above when securing the screw

(

.

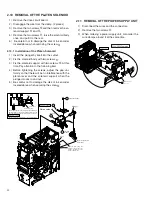

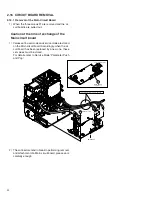

2.11 REMOVAL OF THE POWER SUPPLY UNIT

1) Disconnect the wires and the connectors.

2) Remove the two screws

0

.

3) When ordering a power supply unit, also order the

wire clamps around it at the same time.

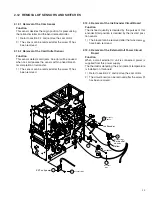

Explanation drawing 1

Explanation drawing 1

Engage the bearing with

the rear frame.

11

19

QYSPSPD4008Nx2

(TSS0179)

12

Plunger

17

QYSPSPD

4008Nx2

Clamp

Gap

Platen lever

Solenoid support

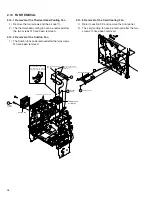

Lead the wire along the

bracket so that it does not

become an obstacle on the

inside of the bracket.

Before tightening the screws, adjust the gap uniformly so

that there will be no interference with the platen lever and

the solenoid support when the plunger moves in and out.

Caution for the time of installation of the solenoid support

Platen solenoid

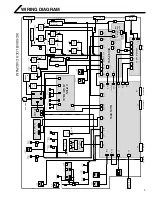

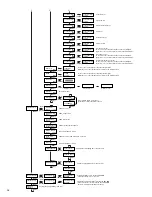

100V/200VCommon

H1

H2

CN8

CN4

CN5

CN6

CN7

CN8

CN4

CN2

CN1

CN3

H1

H2

6

KWS0639-001

POWER SUPPLY SA

F3

H1

H2

10

KJJ46271-003x2

H1=Retransfer heater

H2=Bend Remedial heater