25

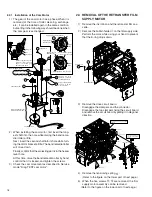

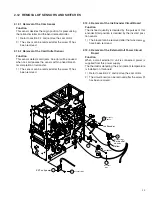

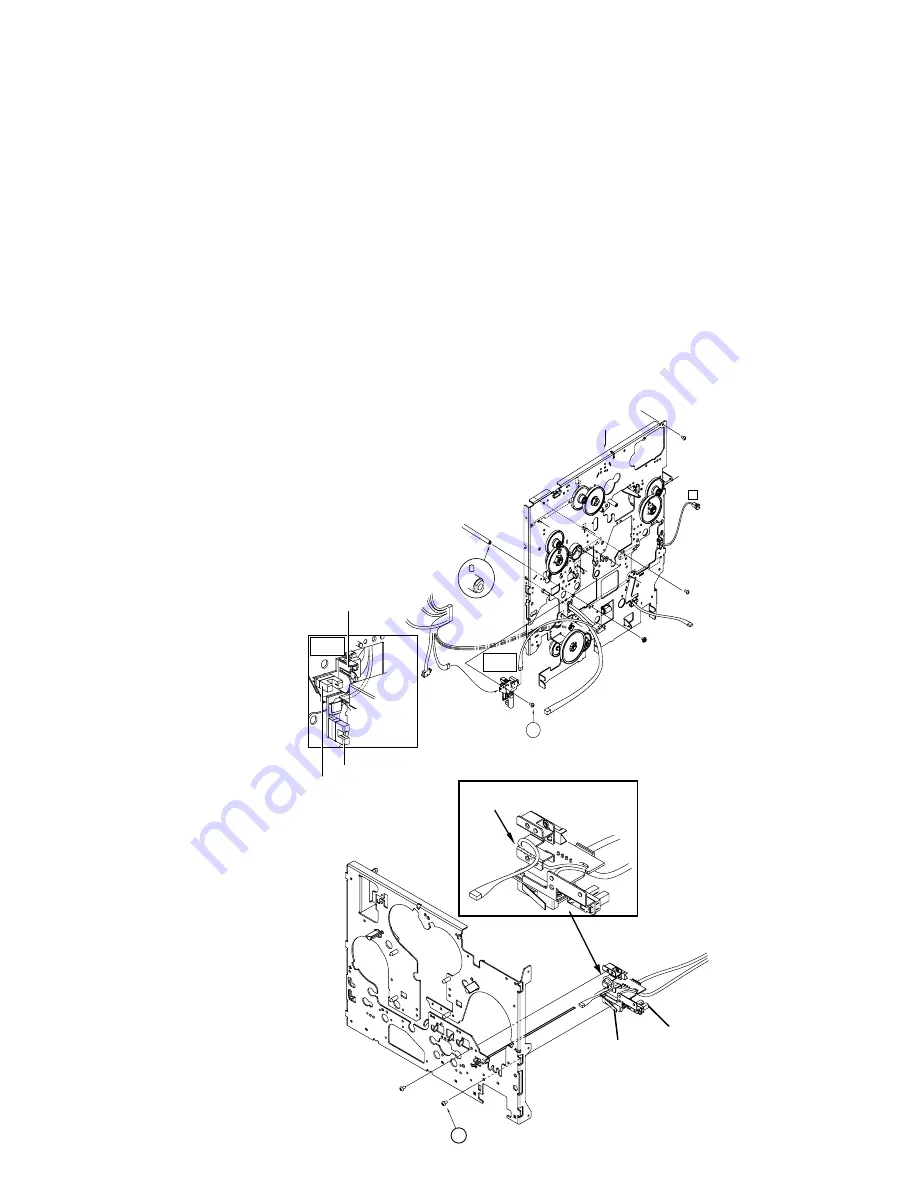

2.12.9 Removal of the Retransfer Film Mark/Ink

Start Position Sensor Circuit Board and the

Card Edge Sensor

Function

•

Card edge sensor

This sensor decides the card position at the time of

card retransfer.

•

Retransfer Film mark sensor

This sensor detects the black bar on the film and

selects the panel for printing.

•

Ink start position sensor

This sensor detects the boundary between magenta

and cyan ink. Next, the pulses of the rotary encoder

are detected and movement is made to yellow.

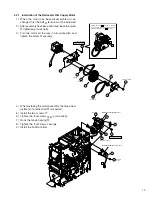

1) When a magnetic encoder is built-in, refer to "Con-

nection of optional parts" and remove the encoder.

2) Remove the feed roller marked with

*

in the lower

drawing of section 2.15.1 “feed roller removal”.

3) The sensor bracket holding the sensor can be re-

moved when the screw

#

has been removed.

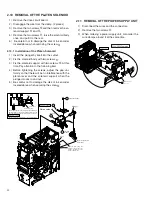

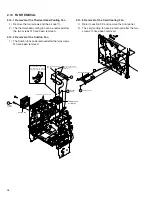

2.12.10 Removal of the C.L. Interlock Circuit Board

and the Card Supply Sensor

Function

•

C.L. interlock switch

This sensor detects the presence or absence of the

cleaning unit.

When the switch is OFF, no power is supplied to the

driver IC for the card supply motor and the turnover

motor.

•

Card supply sensor

This sensor checks whether cards are being sup-

plied or not.

1) Refer to section 2.9 and remove the front panel.

2) The sensor bracket holding these two sensors can

be removed when the screw

6

has been removed.

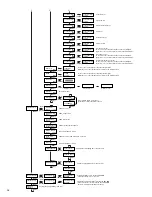

REAR PLATE SA

13

F1

( side)

Explanation

drawing 4

Explanation

drawing 4

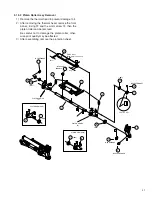

Route the edge sensor

wire underneath the film

mark sensor between

the circuit boards.

Card edge sensor

Retransfer film mark sensor

Ink start position

sensor

6

Pass the wire through the notch

in the bracket.

Card supply sensor

C. LInterlock switch